Extinguishment combination with hot gas sol

A fire extinguishing composition and the technology of the composition, applied in the direction of fire prevention equipment, etc., can solve the problems of fire extinguishing device product cost increase, fire extinguishing ability, volume and weight increase, etc., and achieve the effect of low price, high oxidation performance and wide source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

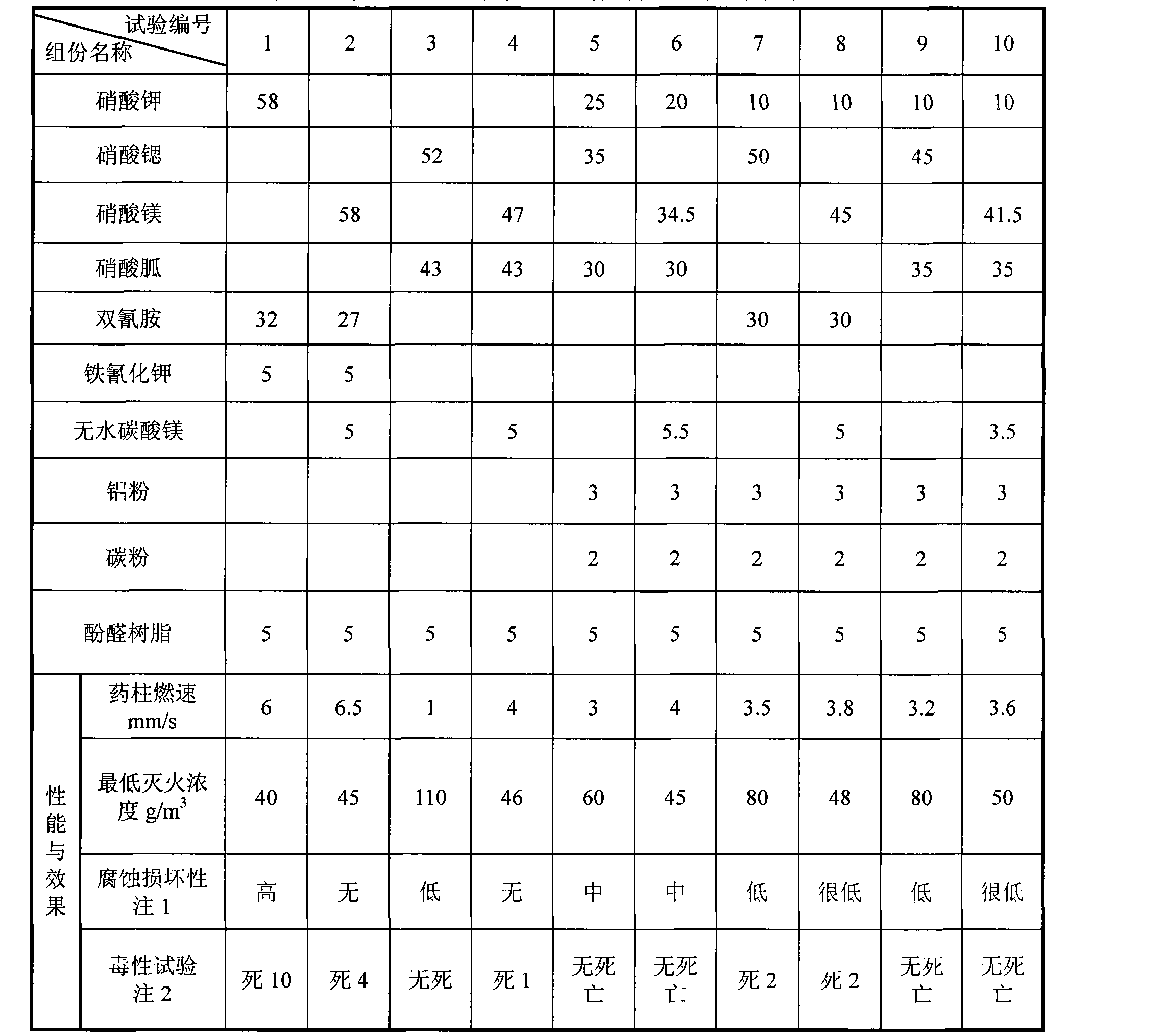

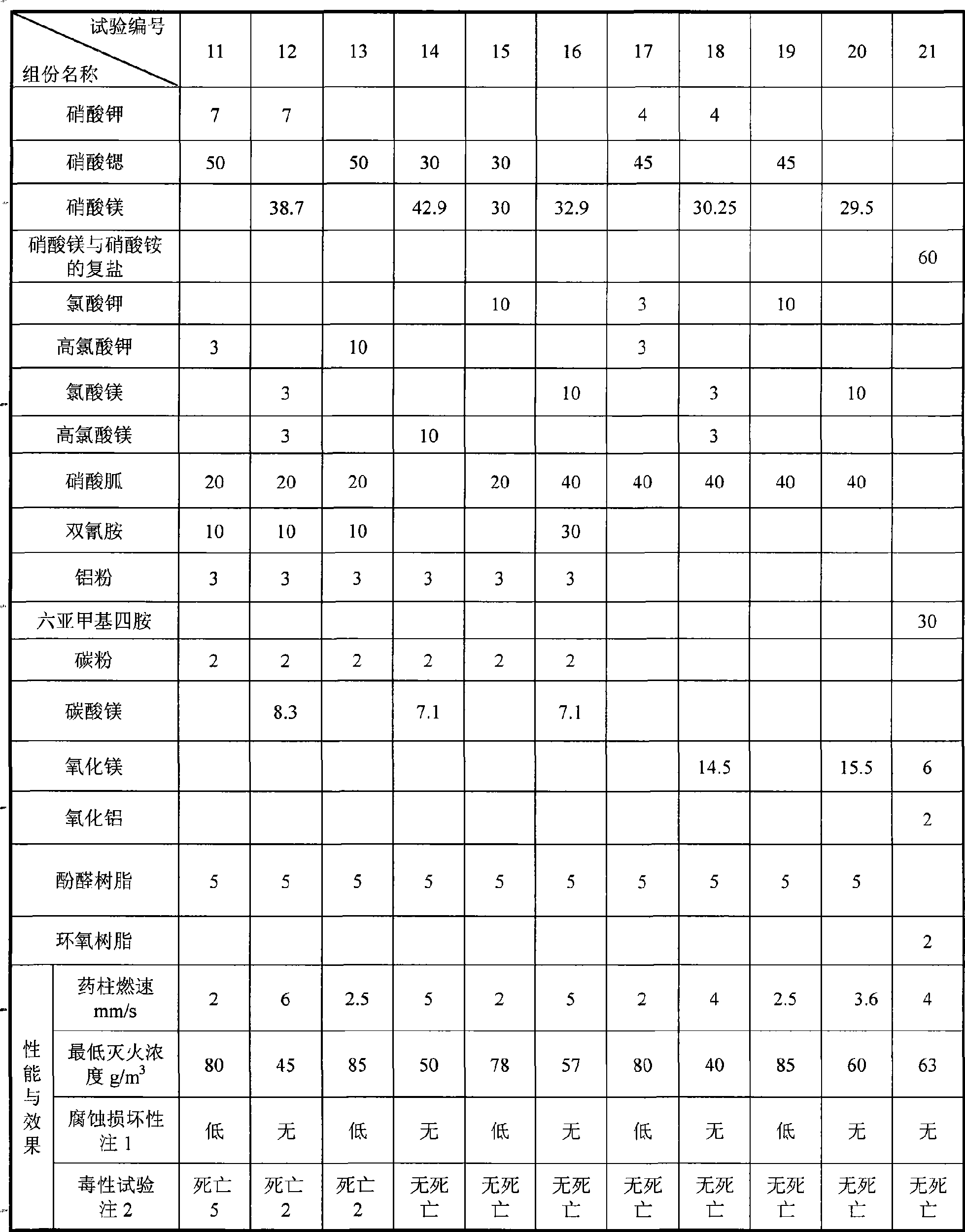

[0051] This embodiment is the enlargement and extension of Test No. 2 in Table 1. Composition and mass percentage thereof are in this embodiment:

[0052] Magnesium nitrate 50%~60%

[0053] Potassium ferricyanide 7%~10%

[0054] Dicyandiamide 20%~30%

[0055] Magnesium carbonate 5%~20%

[0056] Phenolic resin 2%~5%

[0057] Compared with the performance of the test No. 1 composition in Table 1, the performance of the No. 2 composition is obviously superior to that of Composition 1, with high fire extinguishing efficiency and no corrosion.

Embodiment 2

[0059] Embodiment 2 is the enlargement and expansion of No. 4 in Table 1. Composition and mass percentage thereof are in this embodiment:

[0060] Magnesium nitrate 40%~55%

[0061] Guanidine nitrate 40%~45%

[0062] Magnesium carbonate 5%~15%

[0063] Phenolic resin 2%~5%

[0064] This embodiment is obviously better than the comparative example of No. 3: the burning rate is not increased, and the combustion deposits have no corrosion; the fire extinguishing ability is equivalent to that of No. 3.

Embodiment 3

[0066] This embodiment is the enlargement and expansion of No. 6 in Table 1. Composition and mass percentage thereof are in this embodiment:

[0067] Potassium nitrate 10%~30%

[0068] Magnesium nitrate 30%~40%

[0069] Guanidine nitrate 20%~40%

[0070] Magnesium carbonate 10%~20%

[0071] Aluminum powder 2%~8%

[0072] Toner 0%~5%

[0073] Phenolic resin 2%~5%

[0074] Compared with the comparative example of No. 5, the composition shows that the same formulation of magnesium nitrate and potassium nitrate has similar corrosion damage and toxicity; but the burning rate is accelerated, and the fire extinguishing ability is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com