Zinc-system phosphating solution additive and use method thereof

A zinc-based phosphating solution and additive technology, which is applied in the direction of metal material coating process, etc., can solve the problems of short service life of phosphating solution, environmental treatment burden, and difficulty in washing, and achieves low cost, reduced slag, and film formation. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

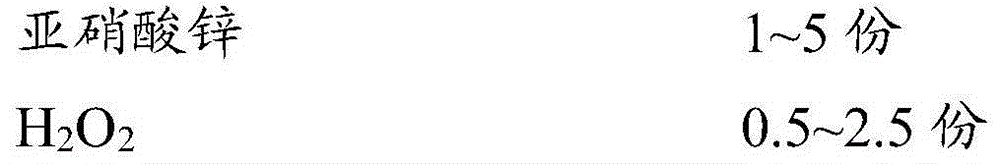

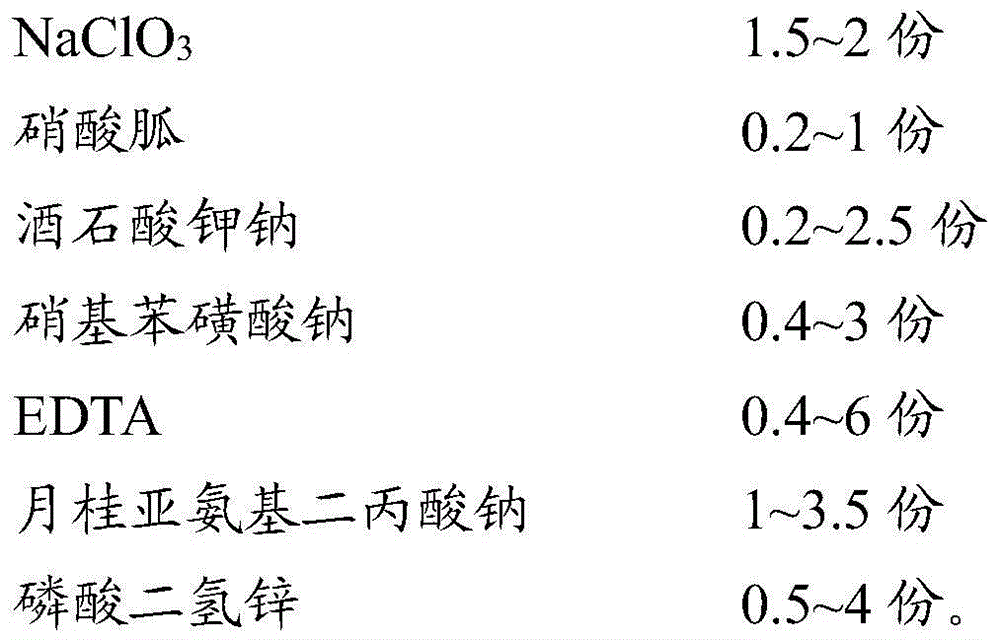

[0017] (1) The components of zinc phosphating solution additives are:

[0018]

[0019] (2) Preparation of phosphating solution:

[0020] First, stir the main salt of the phosphating solution with water, add nitric acid or phosphoric acid to dissolve, then add appropriate amount of zinc nitrite, H 2 o 2 , NaClO 3 Stir while adding, then add tartrate, guanidine nitrate and nitrobenzene sulfonate in turn, wait for the temperature of the phosphating solution to drop to room temperature, add organic carboxylate, sodium lauryl iminodipropionate and zinc dihydrogen phosphate, Stir until completely dissolved, and adjust the pH to 2-4.

[0021] (3) Surface treatment:

[0022] Put the metal after degreasing, water washing, rust removal and surface conditioning into the phosphating solution in step (2), and phosphating at 35-45°C for 6-8 minutes to form a uniform gray zinc-based phosphating film .

Embodiment 2

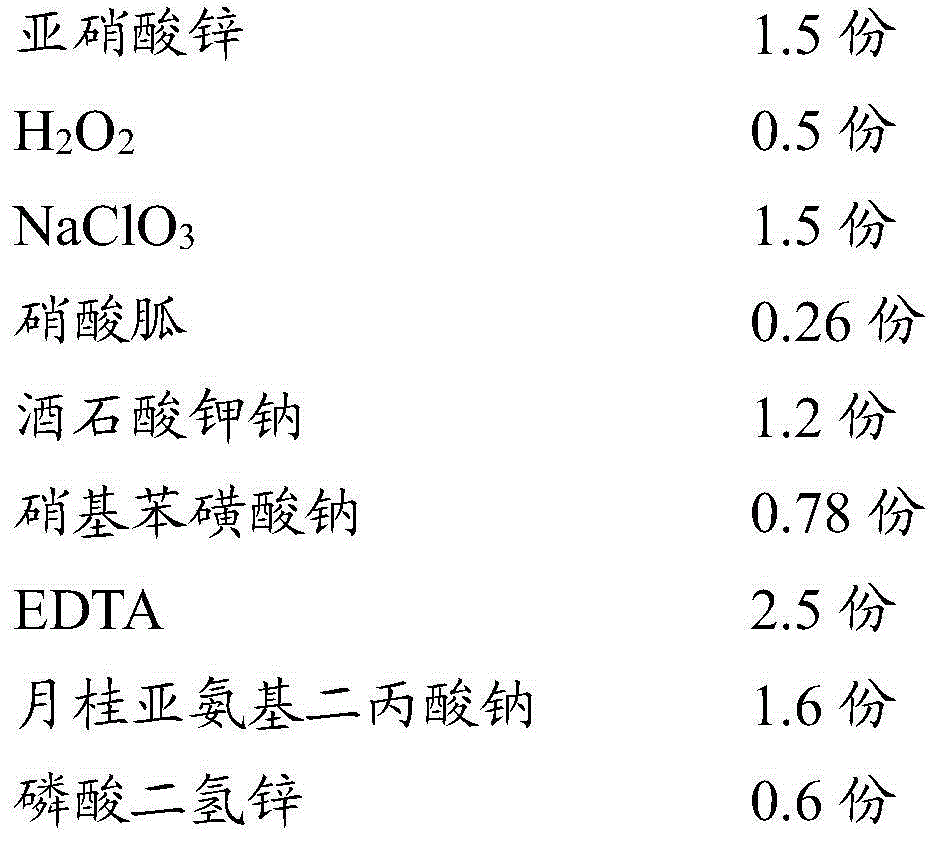

[0024] (1) The components of zinc phosphating solution additives are:

[0025]

[0026]

[0027] (2) Preparation of phosphating solution:

[0028] First, stir the main salt of the phosphating solution with water, add nitric acid or phosphoric acid to dissolve, then add appropriate amount of zinc nitrite, H 2 o 2 , NaClO 3 Stir while adding, then add tartrate, guanidine nitrate and nitrobenzene sulfonate in turn, wait for the temperature of the phosphating solution to drop to room temperature, add organic carboxylate, sodium lauryl iminodipropionate and zinc dihydrogen phosphate, Stir until completely dissolved, and adjust the pH to 2-4.

[0029] (3) Surface treatment:

[0030] Put the metal after degreasing, water washing, rust removal and surface conditioning into the phosphating solution in step (2), and phosphating at 35-45°C for 6-8 minutes to form a uniform gray zinc-based phosphating film .

Embodiment 3

[0032] (1) The components of zinc phosphating solution additives are:

[0033]

[0034] (2) Preparation of phosphating solution:

[0035] First, stir the main salt of the phosphating solution with water, add nitric acid or phosphoric acid to dissolve, then add appropriate amount of zinc nitrite, H 2 o 2 , NaClO 3 Stir while adding, then add tartrate, guanidine nitrate and nitrobenzene sulfonate in turn, wait for the temperature of the phosphating solution to drop to room temperature, add organic carboxylate, sodium lauryl iminodipropionate and zinc dihydrogen phosphate, Stir until completely dissolved, and adjust the pH to 2-4.

[0036] (3) Surface treatment:

[0037] Put the metal after degreasing, water washing, rust removal and surface conditioning into the phosphating solution in step (2), and phosphating at 35-45°C for 6-8 minutes to form a uniform gray zinc-based phosphating film .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com