Method for making semi-finished dental base

A semi-finished product, base technology, applied in dentistry, dental prosthesis, manufacturing tools, etc., can solve the problems of high material consumption, regular refurbishment of milling cutter head wear, and increased operating costs of milling machines, and achieve low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

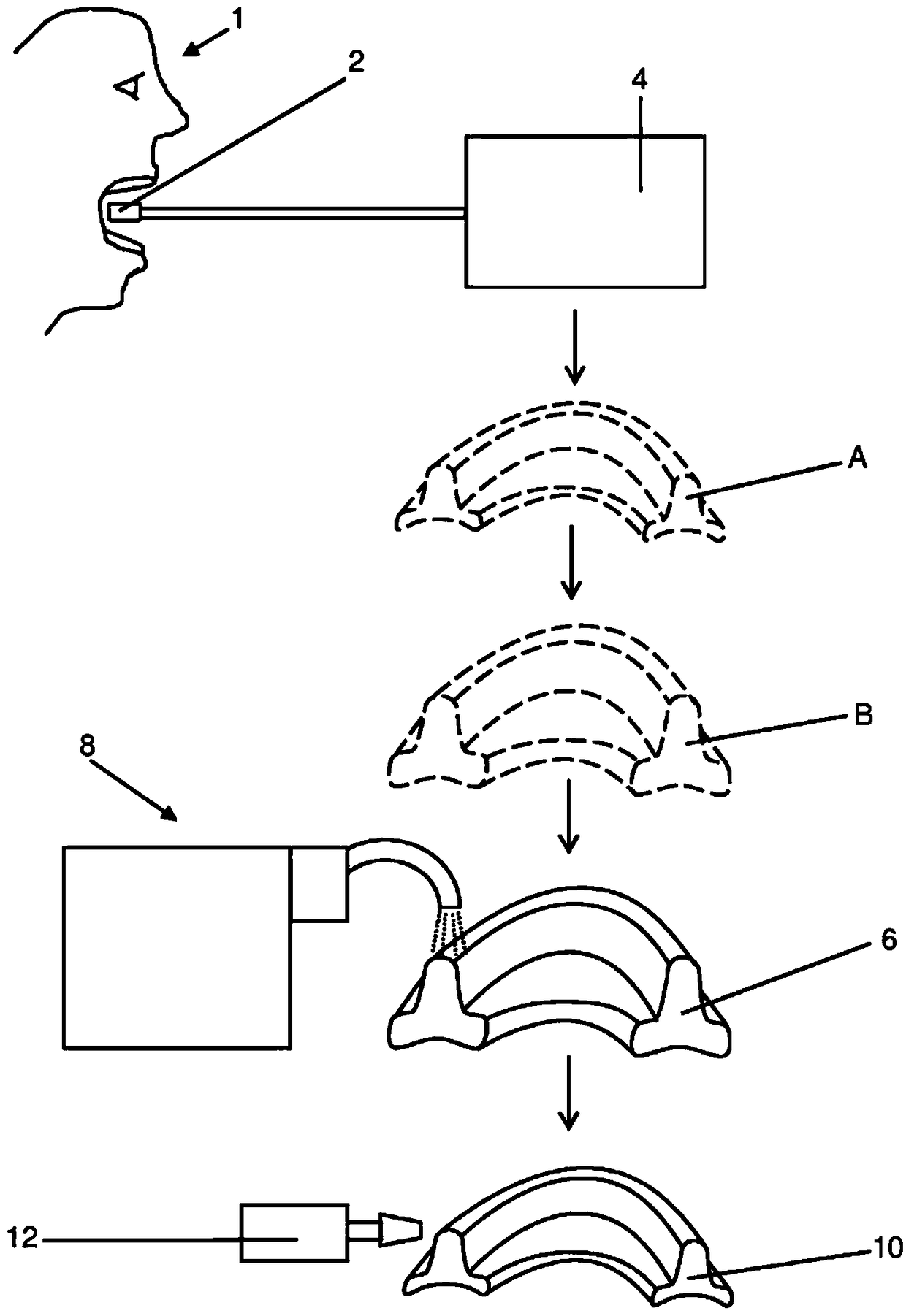

[0058] In a first step, an intraoral scanner 2 is used to acquire a three-dimensional image of the oral cavity of the patient 1 . Mouth at least partially devoid of teeth. The intraoral scanner 2 can be, for example, a suitable stereo camera. The image data of the intraoral scanner 2 is transmitted to the computer 4, and the computer calculates a three-dimensional digital oral model of the oral cavity part related to prosthesis production according to the image information.

[0059] Based on the oral cavity model and possibly other data such as data relating to the occlusion, position and orientation of the denture to be inserted, the position of markers (for adjusting the orientation of the denture base to be produced), with the aid of a bite mold including the occlusal embankment (Bisswall) (Bissschablone) and / or generally at the patient for the adjustment of the articulator (Artikulator), the computer 4 calculates the first digital three-dimensional of the denture base mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com