Zirconia ceramic slurry for manufacturing false tooth as well as preparation method and application thereof

A zirconia ceramic and slurry technology, applied in the field of zirconia denture ceramic materials and ceramic denture crowns, can solve very few problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

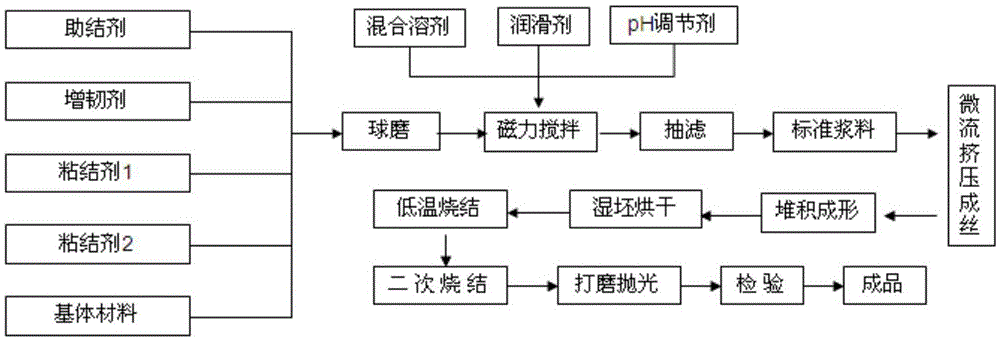

Method used

Image

Examples

Embodiment 1

[0037] According to the present invention, the ceramic material used for micro-fluid extrusion molding to make dentures, the mass percentage of solid raw materials used is:

[0038] 2.4% magnesium oxide, 4.8% zinc oxide, 4.8% silicon oxide, 8% carrageenan, 3Y-ZrO with a particle size of 50-80 nanometers 2 80%.

[0039] The model of the silane coupling agent in the mixed solvent is KH570, the lubricant is glycerol, and the pH regulator is glacial acetic acid. The bonding agent is magnesium oxide, the toughening agent is zinc oxide, the binder is silicon dioxide and carrageenan, and the dental matrix material is 3Y-ZrO with a particle size of 50-80 nanometers. 2 .

[0040] The preparation process is to mix and ball-mill 0.6g of magnesium oxide, 1.2g of zinc oxide, 1.2g of silicon oxide, and 2g of carrageenan for 8 hours in the early stage, and then mix 5g of the obtained mixed powder with a particle size of 50-80 nanometers 3Y-ZrO 220g mixed, high energy ball milled for 20 ho...

Embodiment 2

[0044] According to the present invention, the ceramic material used for micro-flow extrusion molding to make dentures, the mass percentage of raw materials used is:

[0045] 4.7% magnesium oxide, 4.7% zinc oxide, 4.7% silicon dioxide, 7.8% carrageenan, 3Y-ZrO with a particle size of 50-80 nanometers 2 78.1%.

[0046] The preparation process is to mix and ball-mill 1.2g of magnesium oxide, 1.2g of zinc oxide, 1.2g of silicon oxide and 2g of carrageenan for 8 hours in the early stage, and then mix 5.6g of the obtained mixed powder with a particle size of 50-80 nanometers 3Y-ZrO 2 20g mixed, high energy ball milled for 20 hours, fully mixed evenly. Then the mixed solid powder 25.6g was mixed with 270ml of mixed solvent, and stirred on a magnetic stirrer for 5 hours, finally added 4ml of lubricant and 28ml of pH value regulator to adjust the pH value to 4.2, and the solid content was obtained by vacuum filtration. 50% ceramic slurry. The slurry is a ceramic slurry with high so...

Embodiment 3

[0049] According to the present invention, the ceramic material used for micro-flow extrusion molding to make dentures, the mass percentage of raw materials used is:

[0050] 2.2% magnesium oxide, 4.4% zinc oxide, 4.4% silicon oxide, 14.8% carrageenan, 3Y-ZrO with a particle size of 50-80 nanometers 2 74.1%.

[0051] The preparation process is to mix and ball-mill 0.6g of magnesium oxide, 1.2g of zinc oxide, 1.2g of silicon oxide and 4g of carrageenan for 8 hours in the early stage, and then mix 7g of the obtained mixed powder with a particle size of 50-80 nanometers 3Y-ZrO 2 20g mixed, high energy ball milled for 20 hours, fully mixed evenly. Then 27g of the mixed solid powder was mixed with 270ml of mixed solvent, and stirred on a magnetic stirrer for 5 hours, and finally 4ml of lubricant and 34ml of pH regulator were added to adjust the pH to 4.0, and the solid content was obtained by vacuum filtration. % ceramic slurry. The slurry is a ceramic slurry with high solid pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com