A technology for removing laser printing or copying writing on the surface of paper

A laser printing and paper technology, applied in chemical paint/ink remover, coating, etc., can solve unseen problems, achieve the effect of easy procurement, simple and easy removal method, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Take the removal of the handwriting on the surface of the paper after laser printing as an example, where the laser printer used is the HPLaserJet1020 laser printer. The concrete process of this embodiment is:

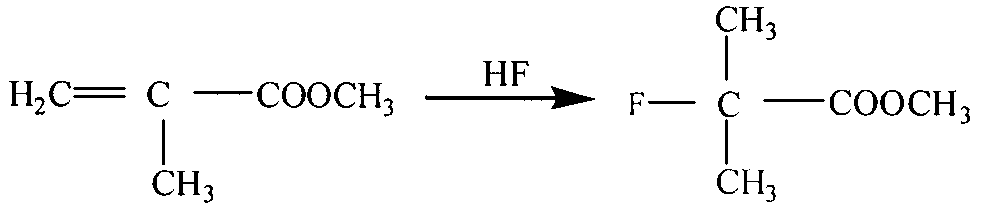

[0029] Step 1: Prepare the solution: Use a graduated cylinder to measure 500mL of denture base resin (Type II) self-setting denture water and 10mL of hydrofluoric acid (analytical grade), and mix them in the container;

[0030] Step 2: Removal of handwriting: completely immerse the paper to be cleaned of handwriting in the prepared solution, and place the solution in an ultrasonic cleaner. Turn on the ultrasonic cleaner and after it has been operating for about 2 minutes, turn off the device and remove the paper from the solution. During this implementation process, due to the pungent odor of tooth dehydration and the volatility of hydrofluoric acid (analytical pure), it is best to carry out under ventilated conditions.

[0031] Step 3: Paper drying: Wash the ...

Embodiment 2

[0033] Taking the removal of writing on the surface of paper after laser copying as an example, the laser copier used is a Canon iR2016J copier. The concrete process of this embodiment is:

[0034] Step 1: Prepare the solution: Use a graduated cylinder to measure 500mL of denture base resin (Type II) self-setting denture water and 10mL of hydrofluoric acid (analytical grade), and mix them in the container;

[0035] Step 2: Removal of handwriting: completely immerse the paper to be cleaned of handwriting in the prepared solution, and place the solution in an ultrasonic cleaner. Turn on the ultrasonic cleaner and after it has been operating for about 2 minutes, turn off the device and remove the paper from the solution. During this implementation process, due to the pungent odor of tooth dehydration and the volatility of hydrofluoric acid (analytical pure), it is best to carry out under ventilated conditions.

[0036] Step 3: Paper drying: Wash the cleared paper in tap water t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com