Method for measuring through hole rate of 3D printing titanium alloy bone trabecula structure oversleeve

A 3D printing and measurement method technology, which is applied in the direction of measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem of inability to determine the position and quantity of trabecular bone blockage, titanium alloy trabecular bone structure sleeve The complex surface and internal structure of the sleeve, the error of detection and other problems, to achieve the effect of simple and effective detection method of through-porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

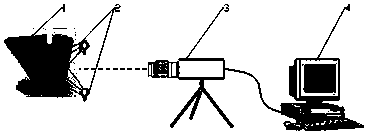

Image

Examples

Embodiment Construction

[0027] First, according to the characteristics of the trabecular bone structure sleeve, the trabecular bone structure sleeve is divided into 12 regions (such as image 3 ), where the spout area is divided into 3 areas, and the vertebral body is divided into 9 areas, a total of 12 areas. The trabecular bone in each area can represent the trabecular bone structure of the cuff.

[0028] The method of obtaining trabecular bone morphology at different positions in the theoretical model of titanium alloy specimens is to use crystal structure trabecular bone or any trabecular bone structure that is conducive to bone ingrowth through topological expansion according to the size and specifications of the sleeve. Form a theoretical model capable of containing the cuff volume of the trabecular structure (e.g. figure 2 ). The volume model of the bone trabecular structure sleeve is cut with the surface of the sleeve and the area with a certain thickness deep into the surface of the sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com