Manufacture of dentures from digital data of oral conditions via cad and rapid manufacturing

A technology of oral condition and complete dentures, applied in the direction of dentures, dentistry, dental prosthesis, etc., can solve problems such as unsatisfactory aesthetic characteristics, and achieve the effect of great precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

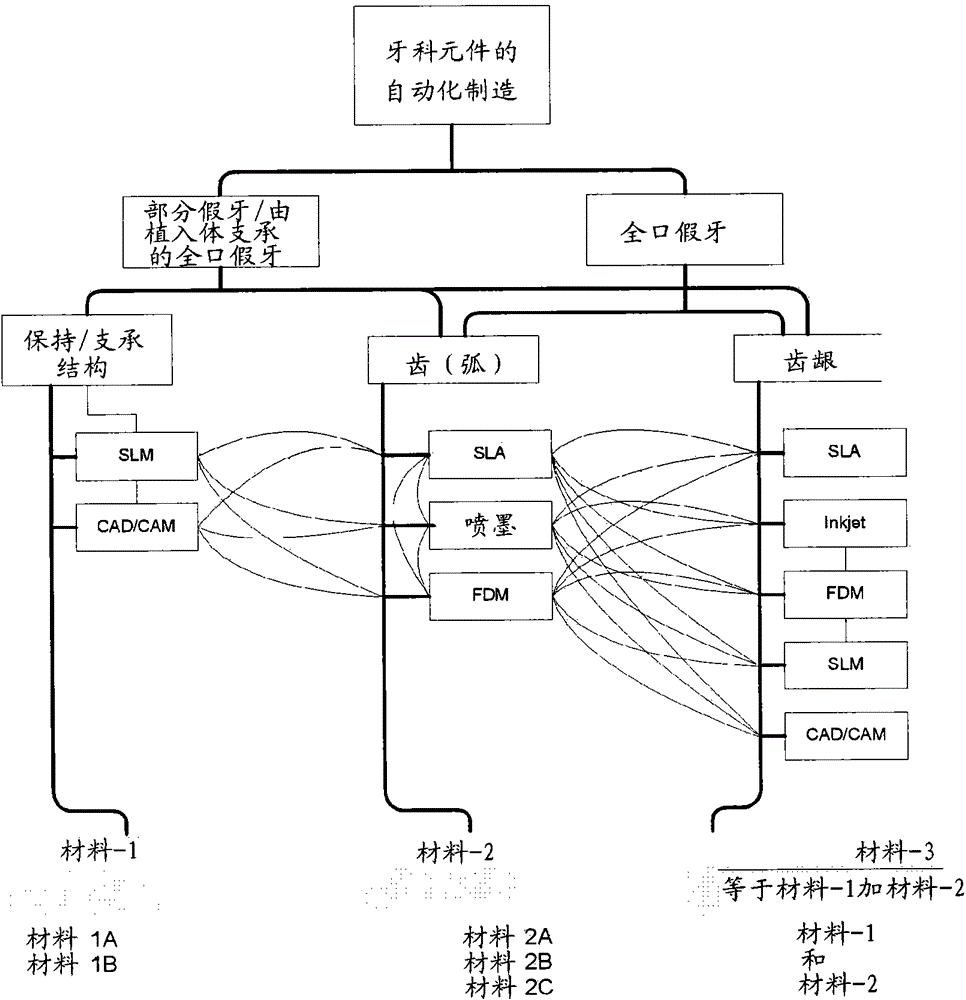

Method used

Image

Examples

Embodiment Construction

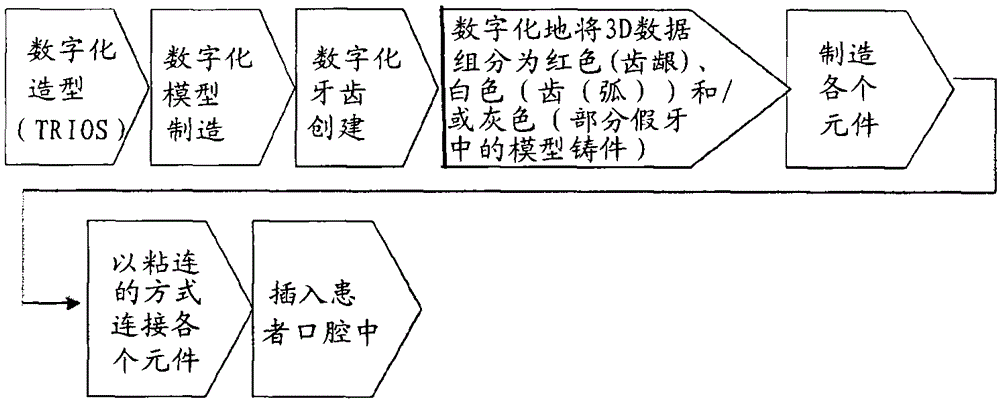

[0061] figure 2 The steps of the embodiment of the method according to the invention shown in are detailed as follows:

[0062] - Modeling by the dentist via an intraoral scanner

[0063] - Generate digitized model data

[0064] - Optional: forward the digitized model to the laboratory

[0065] - Digital tooth creation

[0066] - Optional: Digitize the 3D data set into red (gingiva), white (teeth (dental arch)) and / or gray earlier model castings in the case of body-supported partial dentures)

[0067] - Manufacture of individual elements, utilizing connecting elements if necessary

[0068] - where the inside of the tooth or tooth arch is produced by an automated method and at least one second material is applied thereon as an outer layer by an automated method (preferably the inside of the tooth is produced by means of milling or SLA or inkjet printing (inner core) and at least one second material is applied to the interior with FDM)

[0069] - Connecting the individua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com