Arch tunnel drivage non-repeated-support self-moving complete equipment

A complete set of equipment and arched technology, which is applied in the direction of tunnels, tunnel linings, mine roof supports, etc., to achieve the effects of improving tunneling speed and work efficiency, reducing labor intensity, and reducing power sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

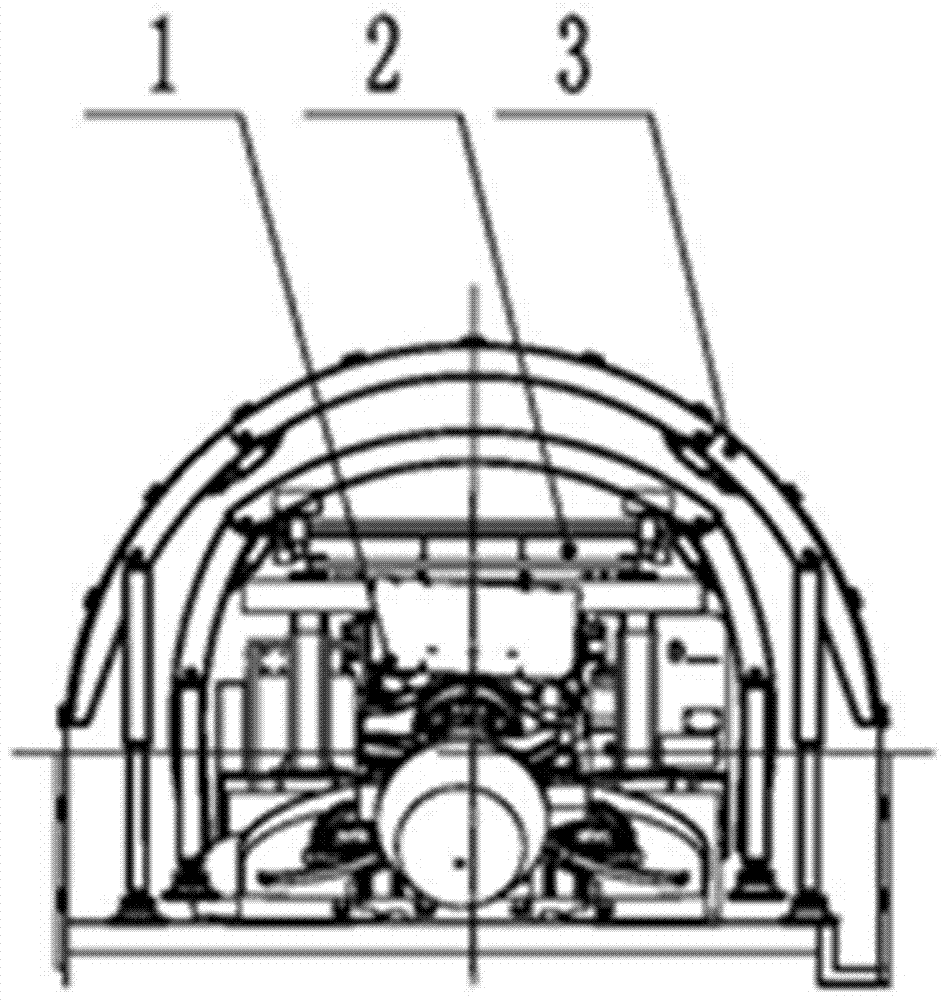

[0039] The self-moving complete set of arched roadway excavation without repeated support in the present invention mainly transports the supporting device at the rear of the working face to the front of the working face through the sliding trolley of the lifting platform, and supports the roadway in time to avoid repeated operation of the roadway Support, to achieve no repeated support, to ensure the integrity of the roof of the roadway. It is beneficial to the roof safety management of the coal mine excavation work, and creates a safe working environment for the fully mechanized excavation face. It can simplify the support procedure and avoid the safety hazard of operators working under the empty roof. Improve the mechanized support operation level of the coal mine driving face, greatly improve the driving speed and work efficiency, reduce the driving cos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com