Room-temperature self-crosslinked aqueous polyurethane-polyacrylate containing fluoroalkyl groups in lateral chains and preparation method thereof

A water-based polyurethane and polyacrylate technology, applied in the direction of polyurea/polyurethane coatings, coatings, etc., can solve the problems of unstable coating performance, unfavorable large-area construction, etc., to facilitate construction, shorten construction period, and widen the scope of application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

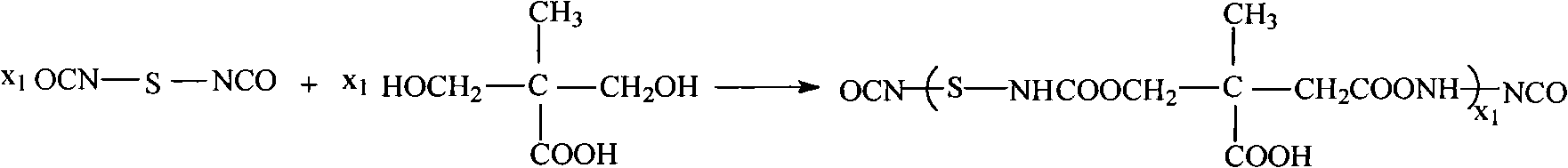

[0065] (1) Dehydrate 0.2mol of fluorine-containing polyether polyol resin with a molecular weight of 2000g / mol at 110°C for 1.5h under a vacuum of 0.08MPa, then add 0.22mol of MDI, stir under nitrogen protection, and place at 60°C React at constant temperature for 2 hours to obtain the FPU prepolymer containing -NCO end group.

[0066] (2) Add 6% hydrophilic chain extender dimethylolpropionic acid (DMPA) to the prepolymer of the prepared step (1), and react at a constant temperature of 80°C for 3h to obtain carboxyl group-containing Hydrophilic FPU prepolymer.

[0067] (3) Cool the carboxyl-containing hydrophilic FPU prepolymer obtained in step (2) to 40°C, add triethylamine (TEA) to the reactor in an equimolar ratio to DMPA, and pass it into the reactor for nitrogen protection , stirred rapidly at normal pressure and 400rpm for 15 minutes, and obtained a salt-forming hydrophilic FPU prepolymer after fully reacting.

[0068] (4) Discharge the hydrophilic FPU prepolymer forme...

Embodiment 2

[0074] In step (1), the molecular weight of the polyether polyol resin containing fluoroalkyl is changed from 2000g / mol to 1000g / mol, the dehydration treatment time is changed from 1.5h to 2h, and the MDI of 0.22mol is changed to 0.30mol HMDI, other steps are all identical with embodiment 1.

[0075] The solid content of the aqueous polyurethane emulsion containing fluoroalkyl groups in the side chain is 31%, the contact angle of the film-former to water is 107°, the tensile strength is 17.3MPa, and the elongation at break is 100%.

Embodiment 3

[0077] In step (1), the molecular weight of the polyether polyol resin containing fluoroalkyl is changed from 2000g / mol to 10000g / mol, the dehydration treatment time is changed from 1.5h to 1h, and the treatment temperature is changed from 110°C to 120°C , change the constant temperature reaction 2h at 60°C to 80°C constant temperature reaction 1h, in step (5), the ADH chain extender addition is changed from 3% to 1% by volume equivalent to the emulsified FPU, and other steps are all the same as in Example 1 same.

[0078] The solid content of the aqueous polyurethane emulsion containing fluoroalkyl groups in the side chain is 26%, the contact angle of the film-former to water is 79°, the tensile strength is 11.5MPa, and the elongation at break is 300%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com