Prestressed pipe pile construction method under boulder group geological conditions

A technology of prestressed pipe piles and geological conditions, which is applied in the direction of sheet pile walls, foundation structure engineering, buildings, etc., to achieve the effects of improving bearing capacity, increasing horizontal load capacity, and increasing frictional resistance around piles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the purpose is only to better understand the content of the present invention. Therefore, the examples given do not limit the protection scope of the present invention.

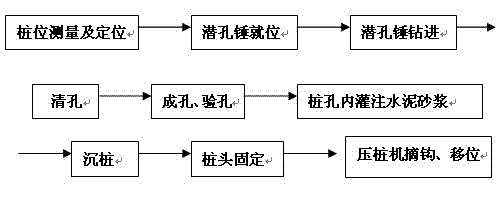

[0018] see figure 1 , the prestressed pipe pile construction method under the geological conditions of the boulder group described in the embodiment of the present invention is carried out according to the following steps:

[0019] ⑴Pile position measurement and positioning:

[0020] Based on the coordinate measurement control point set by the owner in the field area as the benchmark, the center pile of each group of piles and the piles of any pile coaxial with the center pile are released one by one through coordinate conversion, rotation angle, distance measurement, and fixed point by using the range finder. The other pile positions of each group of piles are released one by one ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com