Aqueous siliconiting polymer emulsion as well as preparation method and use thereof

A polymer emulsion and silane compound technology, applied in the direction of chemical instruments and methods, applications, lubricating compositions, etc., can solve problems such as not wanting to add inorganic particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0073] Preparation method of aqueous silylated polymer emulsion

[0074] The invention uses a specific silane compound to prepare a stable water-based silylated polymer emulsion, which can be prepared in various ways, and the process is simple, flexible and diverse, and easy to operate.

[0075] In one embodiment A of the preparation method of the silylated polymer emulsion of the present invention (abbreviated herein as "simultaneous addition of silane method"), the method comprises the following steps (see Figure 4 ):

[0076] (1) blending of silylated polymer, optional emulsifier, and optional emulsification aid to form component AI;

[0077] (2) Optionally, mixing silane compound, water and optional nano silicon dioxide to form component AII;

[0078] (3) under agitation, add the component AII obtained in the step (2) to the component AI obtained in the step (1), or add the silane compound, water and non-essential nano-silicon dioxide respectively synchronously, after c...

Embodiment 1

[0135] Aqueous Silylated Polymer Emulsion Formulation 1 (Method B)

[0136] Composition Amount (g)

[0137] Vinyltris(β-methoxyethoxy)silane 7.0

[0138] Vinyldiethoxysilane-terminated polydimethylsiloxane 33.0

[0139] water 57.0

[0140] Ammonium Lauryl Polyoxyethylene(2) Ether Sulfate 2.0

[0141] Cetyl polyoxyethylene (30) ether 1.0

[0142] Polyoxyethylene (5) sorbitan monooleate 0.5

[0143] In a high-speed dispersion kettle, add 33.0 grams of vinyldiethoxysilane-terminated polydimethylsiloxane (weight average molecular weight 12,000, see U.S. Patent No. 3,971,751. The silane described in this example and the following examples Capping means capping with the silane at both ends of the polymer chain), 7.0 grams of vinyltris(β-methoxyethoxy)silane, 2.0 grams of lauryl polyoxyethylene ether (2) sulfuric acid Ammonium, 1.0 gram of cetyl polyoxyethylene (30) ether, 0.5 gram of polyoxyethylene (5) sorbitan monooleate, stirred at 2000rpm rotating speed at room temperature...

Embodiment 2

[0146] Aqueous Silylated Polymer Emulsion Formulation 2 (Method B)

[0147] Composition Amount (g)

[0148] Isobutyltriethoxysilane 10.0

[0149] 50% by weight nano silica hydrosol 16.0

[0150] Triethoxysilane-terminated polydimethylsiloxane 59.0

[0151] Sodium Lauryl Sulfate 0.5

[0152] Rhodia CO436 0.5

[0153] Rhodia CA897 0.5

[0154] water 14.0

[0155] 10% by weight hydrochloric acid to pH=8

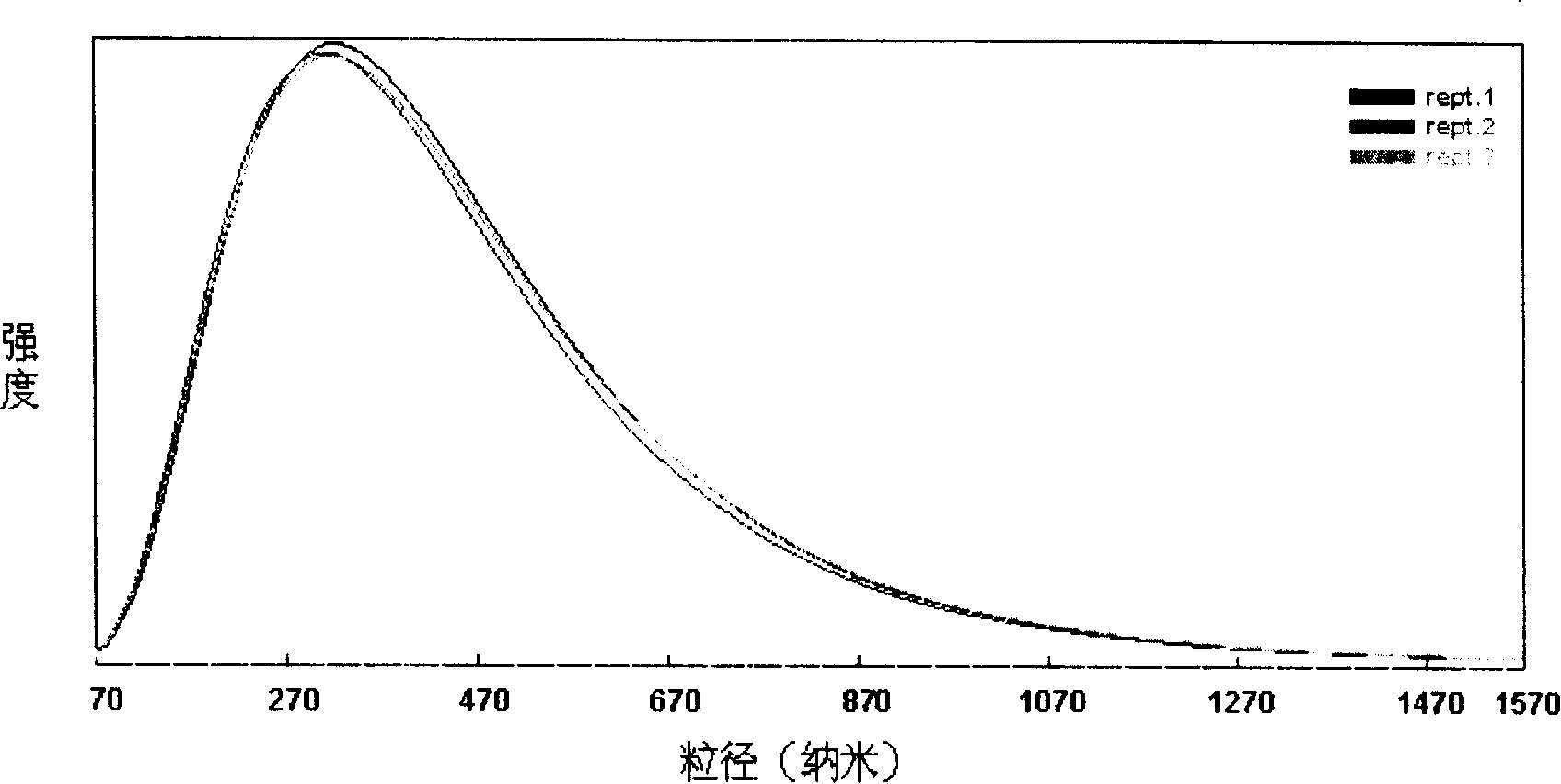

[0156] In the high-speed dispersion kettle, add 59.0 grams of triethoxysilane-terminated polydimethylsiloxane (weight average molecular weight 60000, Henkel AG, Dusseldorf, Germany, see U.S. Patent No.5,300,608 ), 10.0 grams of isobutyltriethoxysilane, 0.5 grams of sodium lauryl sulfate, 0.5 grams of Rhodia CO436 (anionic surfactant, polyethylene oxide (4) alkylphenol ether sulfate, Rhodia Corporation) and 0.5 Gram Rhodia CA897 (nonionic surfactant, polyoxyethylene (40) nonylphenol ether, Rhodia company), at room temperature 2000rpm rotating speed stirs 10 minutes and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com