Method for preparing anti-aging leakage-proof chemical barrel

A chemical barrel and anti-leakage technology, applied in the direction of coating, etc., can solve the problems of anti-aging, poor heat insulation performance, etc., and achieve the effect of excellent anti-aging performance, good dispersion, and increased interface effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

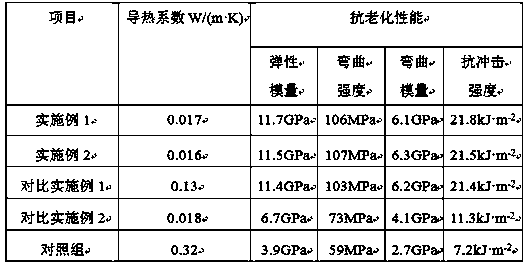

Examples

Embodiment 1

[0028] A method for preparing an anti-aging anti-leakage chemical barrel, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0029] (1) Preparation of functionalized modified nano-hydroxyapatite:

[0030] After dissolving 2 parts of nano-stearic acid in 60°C absolute ethanol, add it to 6 parts of nano-hydroxyapatite slurry, heat and stir at 60°C for 2 hours, centrifuge and wash 3 times with 60°C absolute ethanol, dry, Grinding to obtain functionalized modified nano-hydroxyapatite;

[0031] Wherein, the concentration of nano-hydroxyapatite slurry is 5%;

[0032] (2) Preparation of nitrogen-doped carbon / silica-graphene composite:

[0033] Put 50 parts of nitrogen source, 5 parts of carbon source, 2 parts of silica nanoparticles, and 1 part of graphene oxide treated with surface silanization modification into a ball mill jar, add absolute ethanol and ball mill for 3 hours, and place in a 60°C oven Dry ov...

Embodiment 2

[0040] A method for preparing an anti-aging anti-leakage chemical barrel, characterized in that it comprises the following steps, and the following raw materials are calculated in parts by weight:

[0041] (1) Preparation of functionalized modified nano-hydroxyapatite:

[0042] After dissolving 4 parts of nano-stearic acid in 65°C absolute ethanol, add it to 9 parts of nano-hydroxyapatite slurry, heat and stir at 65°C for 1 hour, centrifuge and wash 3 times with 65°C absolute ethanol, dry, Grinding to obtain functionalized modified nano-hydroxyapatite;

[0043] Wherein, the concentration of nano-hydroxyapatite slurry is 10%;

[0044] (2) Preparation of nitrogen-doped carbon / silica-graphene composite:

[0045] Put 100 parts of nitrogen source, 10 parts of carbon source, 3 parts of silica nanoparticles, and 2 parts of graphene oxide treated with surface silanization modification into a ball mill jar, add absolute ethanol and ball mill for 4 hours, and place in a 65°C oven Dry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com