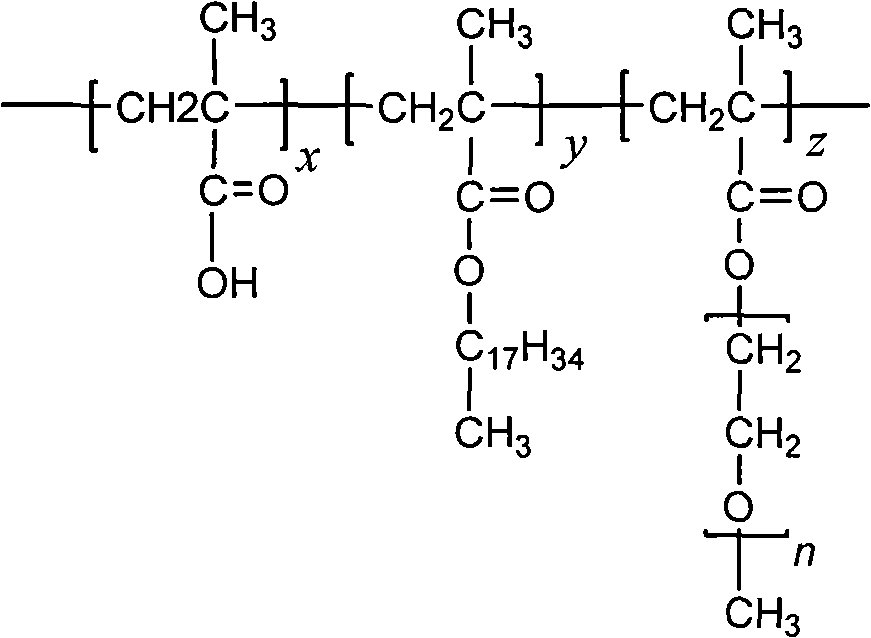

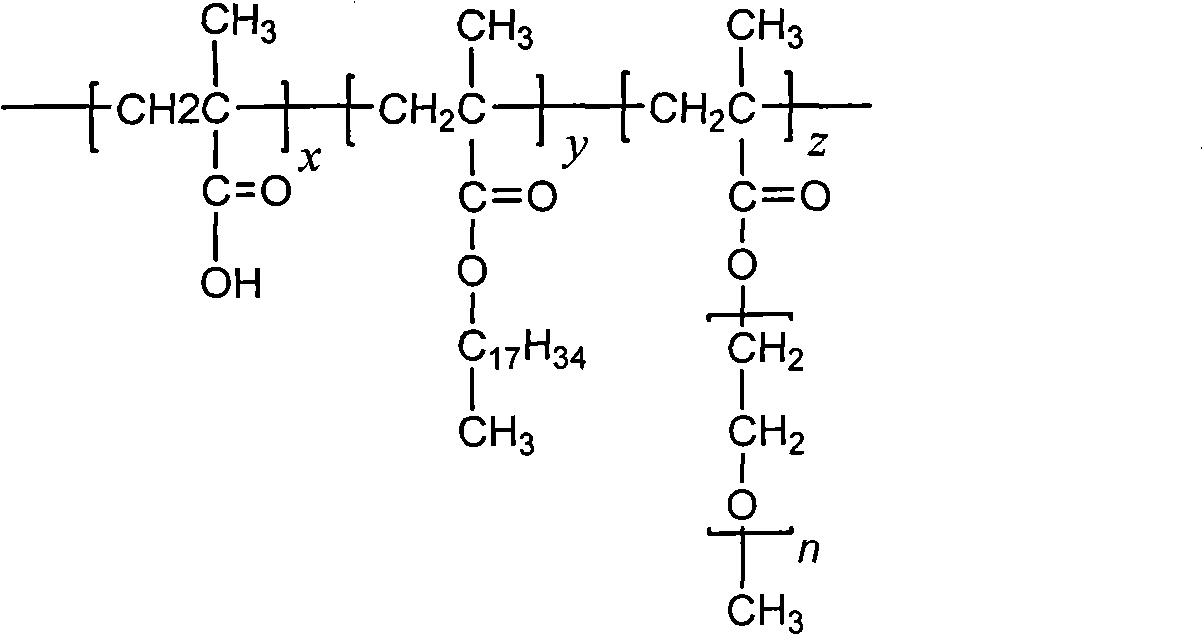

Acrylic ester polymer surfactant and preparation method thereof

An acrylate and surfactant technology, applied in the field of acrylate polymer surfactant and its preparation, can solve the problems of unfavorable promotion and utilization, high reaction conditions, increased cost, etc., and achieves a favorable promotion and application , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] According to the molar ratio of 1:1:1:6, respectively weigh methacrylic acid (MAA), stearyl methacrylate (SMA), polyethylene glycol methacrylate (PEGMA) and solvent isopropyl Alcohol, mix and stir, pour one-half of the mixture solution into a three-necked flask, add the initiator BPO, which is 1 / 100 of the sum of the three monomers, stir, and react under the conditions of 82°C constant temperature oil bath and nitrogen protection After 1.5 to 2 hours, the remaining mixture solution was dropped into the reactor through the dropping funnel within 2 to 2.5 hours, and the reaction was continued for 2.5 to 3 hours before stirring and heating were stopped. The resultant was distilled under reduced pressure for 3 h, and then dried in a vacuum oven at 40-60° C. to constant weight. The desired product was obtained in >90% yield as measured. The molecular weight, molecular weight distribution and polymer structure of the product were detected by gel permeation chromatography and...

Embodiment 2

[0024] According to the molar ratio of 2:1:1:8, respectively weigh methacrylic acid (MAA), stearyl methacrylate (SMA), polyethylene glycol methacrylate (PEGMA) and solvent isopropyl Alcohol, mix and stir, pour one-half of the mixture solution into a three-necked flask, add the initiator BPO, which is 1 / 100 of the sum of the three monomers, stir, and react under the conditions of 82°C constant temperature oil bath and nitrogen protection After 1.5 to 2 hours, the remaining mixture solution was dropped into the reactor through the dropping funnel within 2 to 2.5 hours, and the reaction was continued for 2.5 to 3 hours before stirring and heating were stopped. The resultant was distilled under reduced pressure for 3 h, and then dried in a vacuum oven at 40-60° C. to constant weight. The desired product was obtained in >90% yield as measured. The molecular weight, molecular weight distribution and polymer structure of the product were detected by gel permeation chromatography and...

Embodiment 3

[0026] According to the molar ratio of 3:1:1:10, respectively weigh methacrylic acid (MAA), stearyl methacrylate (SMA), polyethylene glycol methacrylate (PEGMA) and solvent isopropyl Alcohol, mix and stir, pour one-half of the mixture solution into a three-necked flask, add the initiator BPO, which is 1 / 100 of the sum of the three monomers, stir, and react under the conditions of 82°C constant temperature oil bath and nitrogen protection After 1.5 to 2 hours, the remaining mixture solution was dropped into the reactor through the dropping funnel within 2 to 2.5 hours, and the reaction was continued for 2.5 to 3 hours before stirring and heating were stopped. The resultant was distilled under reduced pressure for 3 h, and then dried in a vacuum oven at 40-60° C. to constant weight. The desired product was obtained in >90% yield as measured. The molecular weight, molecular weight distribution and polymer structure of the product were detected by gel permeation chromatography an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com