Plating press of improved structure

A calender and calender roll technology, applied in calenders, paper machines, textiles and paper making, etc., can solve the problems of slow lifting speed, high labor intensity, low production efficiency, etc., to reduce intermediate links and simplify production The effect of high process and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

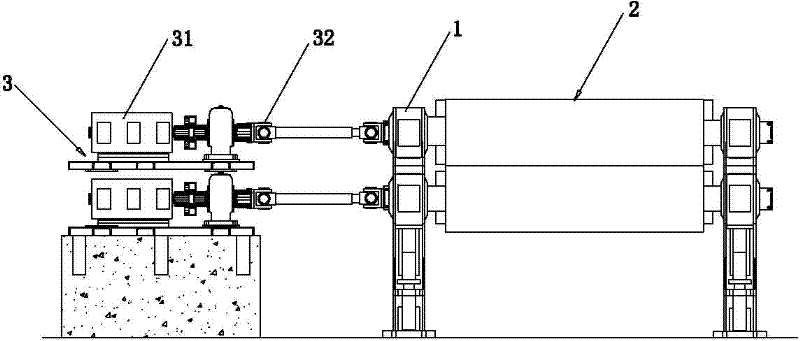

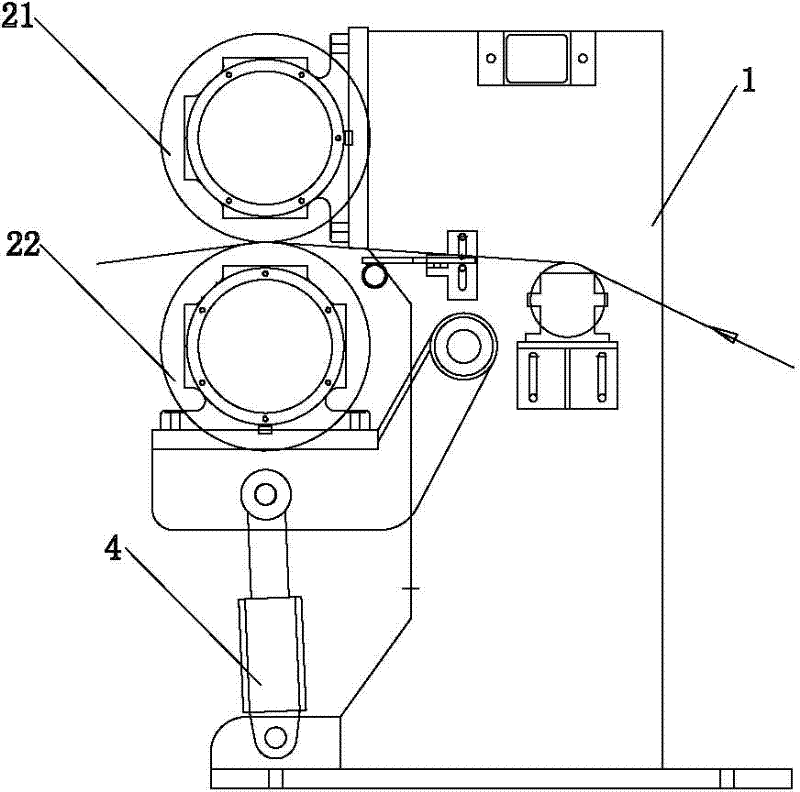

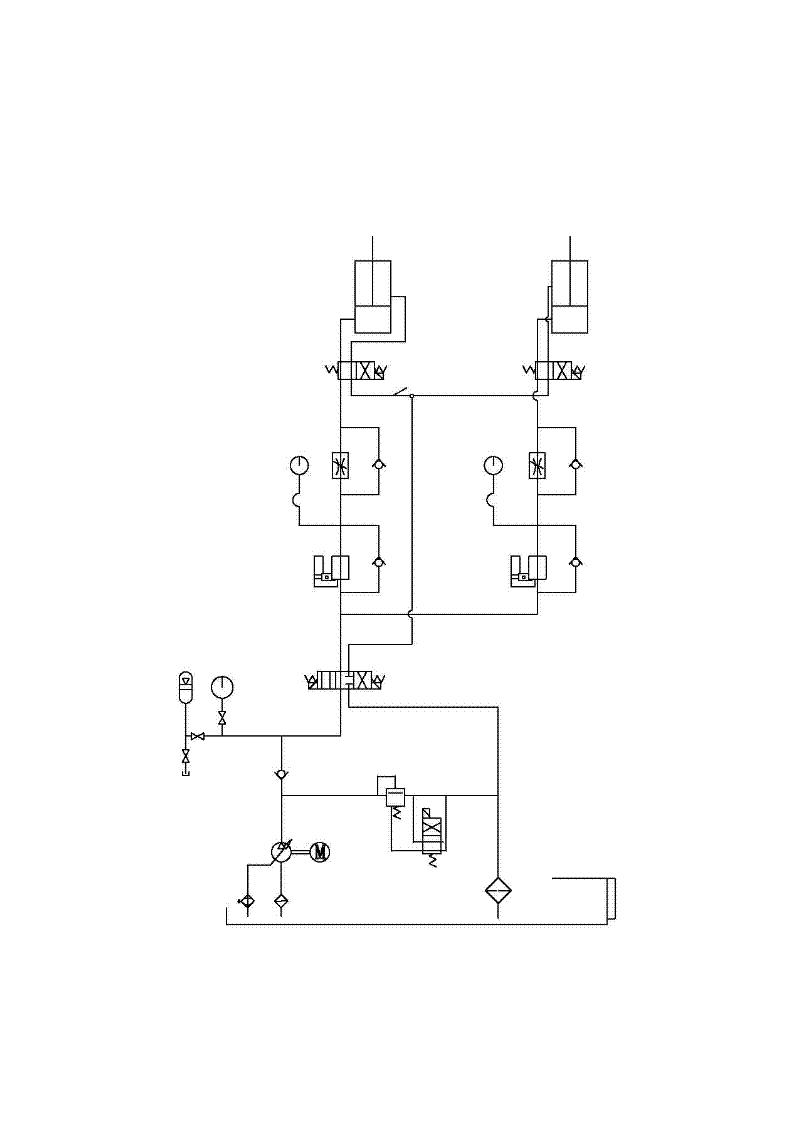

[0024] like Figure 1 to Figure 3 As shown, a calender with improved structure in this embodiment includes a frame 1 and a calender roll 2, the calender roll 2 is connected to the frame 1, and the calender roll 2 includes a top roll 21 and the bottom roll 22, the calender also includes a roll gap adjustment system for adjusting the gap between the top roll 21 and the bottom roll 22 and a double power device 3, and the double power device 3 is driven to connect the Calender roll 2, the roll gap adjustment system includes a PLC control system and a hydraulic station, the hydraulic station is connected to the calender roll 2, and the PLC control system is electrically connected to the hydraulic station. The present invention is used as the calendering equipment of the complete papermaking machine. The roll gap adjustment system can adjust and control the roll gap between the top roll 21 and the bottom roll 22. The PLC control system can receive the lifting signal of the cylinder ...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the dual power device 3 in this embodiment is two variable frequency motors, and an encoder is arranged inside the variable frequency motors. The frequency conversion motor has stable speed regulation, no torque pulsation, maintenance-free, long-lasting operation, and high speed, which greatly improves the degree of mechanical automation and production efficiency, saves energy, and miniaturizes the equipment to increase comfort.

[0034] In this embodiment, the diameter of the calender roll 2 is 500mm, and the calender roll 2 is a middle-high roll formed by alloy forging and heat treatment. The calender roll 2 has a diameter of 500mm, and when the diameter increases, the contact area between the surface of the calender roll 2 and the paper web is larger, and the calendering effect of the paper web is better. The diameter of the calender roll 2 is not limited to 500 mm, and the diameter of the calender roll ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com