Crane encoder mounting structure

An installation structure and encoder technology, applied in the directions of traveling mechanism, transportation and packaging, load hanging components, etc., can solve the complex installation operation, the inability to accurately collect the wheel linear speed data, and the coaxial accuracy of the installation hole and the wheel shaft. higher question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

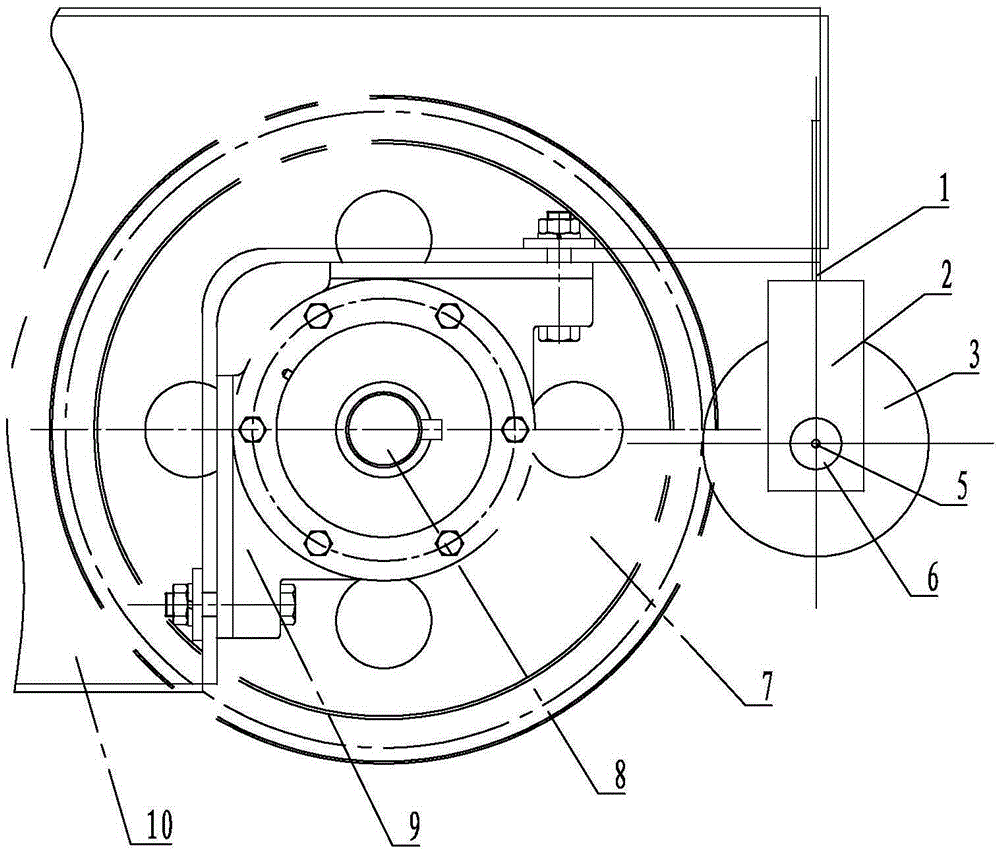

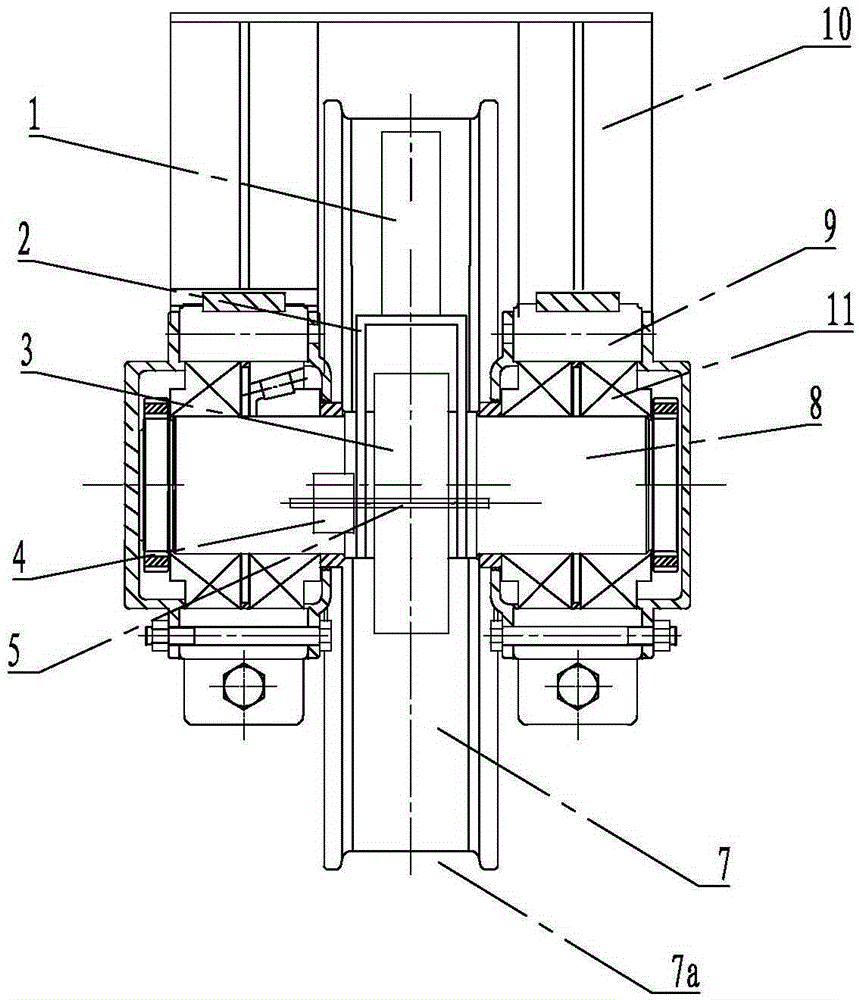

[0021] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the present invention includes a wheel shaft 8 and a wheel 7 fixedly sleeved on the wheel shaft 8, and first bearings 11 are fixedly sleeved at both ends of the wheel shaft 8, and each of the first bearings 11 is installed on a corresponding In the bearing housing 9, these are all identical with the prior art, do not repeat them here. It also includes a "U"-shaped mounting frame 2 relatively fixed to the bearing box 9, and a shield 10 is covered on the wheel 7, and the shield 10 is fixedly connected with the bearing box 9, and at the closed end of the mounting frame 2 A mounting plate 1 is fixedly connected to the outside. In this embodiment, the mounting plate 1 is preferably arranged vertically, and the upper end of the mounting plate 1 is fixed to the shield 10 by bolts. A rotating shaft 5 is pierced between the two side plates of the mounting frame 2, and a second bearing 6 is fixed on the two side ...

Embodiment 2

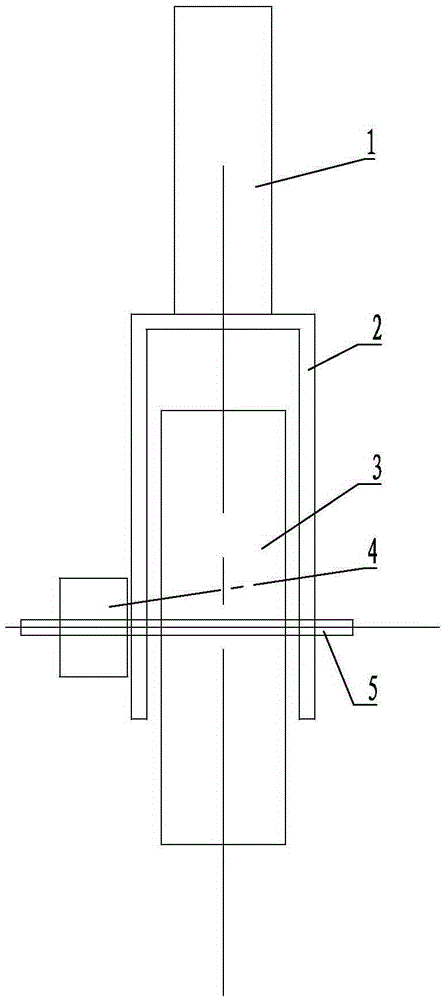

[0024] Such as Figure 5 As shown, the mounting plate 1 is arranged obliquely, and the end of the mounting plate 1 away from the mounting frame 2 is fixed to the shield 10 by bolts. Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com