Automatic feedback control tension taping machine

A technology of automatic feedback and wrapping machine, applied in the directions of transportation and packaging, conveying filamentous materials, thin material processing, etc., can solve the problems of complicated structure of the wrapping machine, inability to detect the breakage of the wrapping tape, etc., and achieve line speed and tension. consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following specific embodiments will be further described in conjunction with the above-mentioned drawings.

[0020] In the following, numerous specific details are set forth in order to provide a thorough understanding of the concepts underlying the described embodiments. It will be apparent, however, to one skilled in the art that the described embodiments may be practiced without some or all of these specific details. In other instances, well known processing steps have not been described in detail.

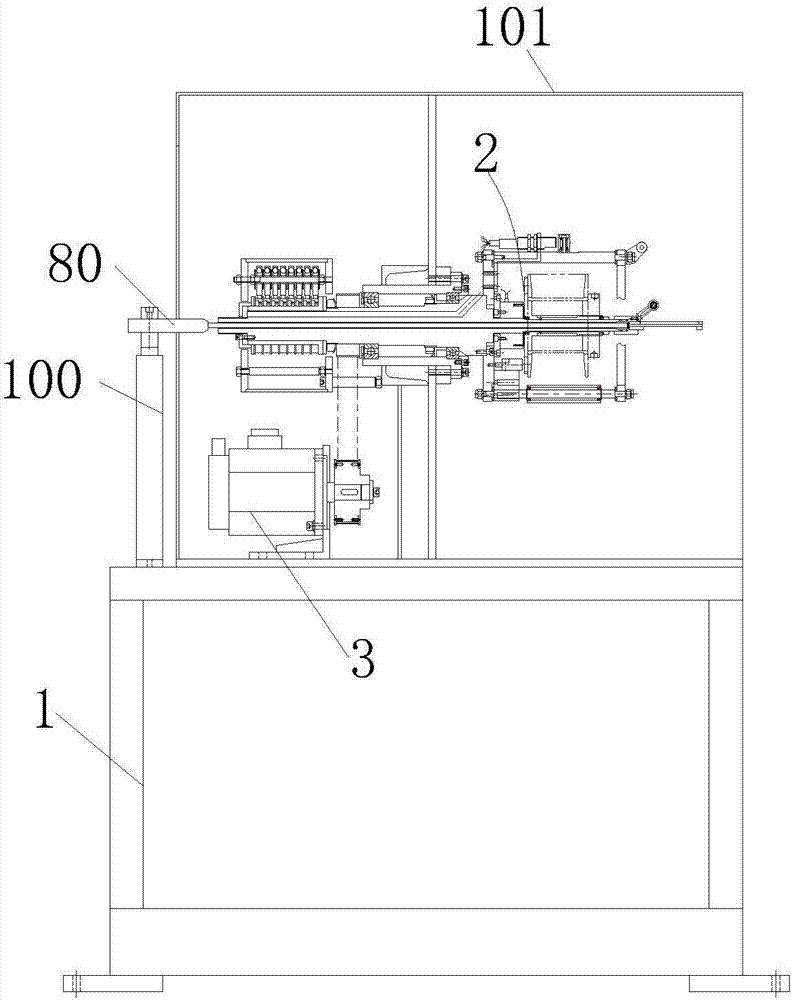

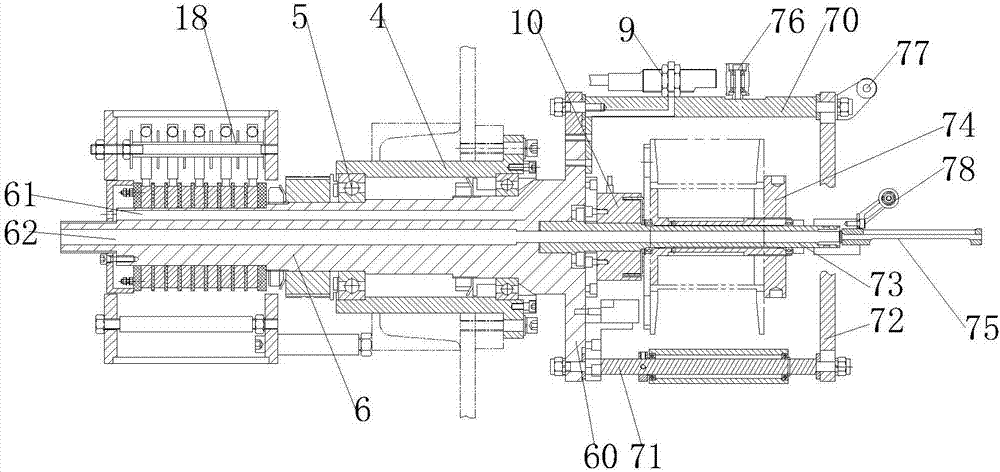

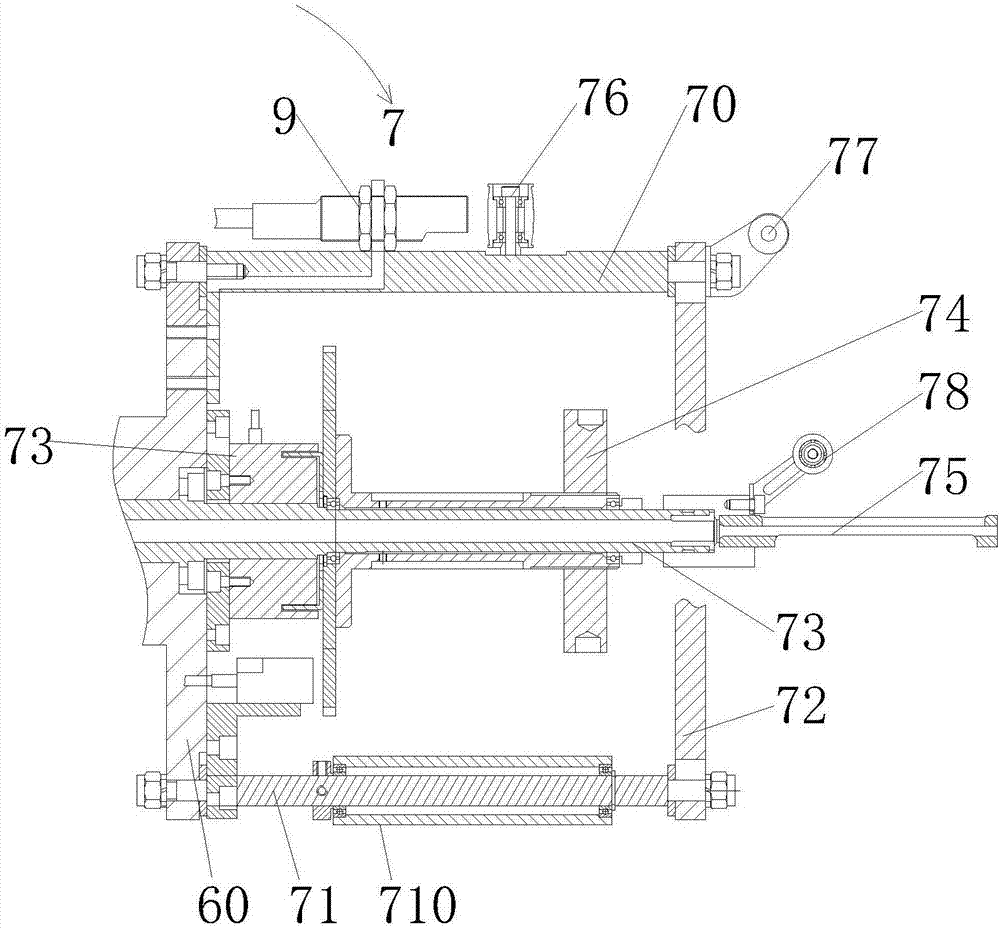

[0021] Such as Figure 1-4 As shown, a kind of automatic feedback control tension taping machine comprises a frame 1, a strapping device 2 arranged on the frame 1, and a drive mechanism 3 for driving the strapping device 2 to run; the strapping The device 2 includes: a bearing seat 4 arranged at the top of the frame 1, a plurality of bearings 5 arranged in the bearing seat 4, a rotating shaft 6 passing through a plurality of the bearings 5 in turn, and an end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com