Low-tension high-synchronization ultrathin film slitting machine

An ultra-thin film, low tension technology, applied in the direction of thin material processing, winding strips, sending objects, etc., can solve the problems affecting the physical properties of products, product quality consistency, film physical deformation, speed lag, etc., to achieve common phenomena The effect of reducing, overcoming friction, and improving the quality of slitting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

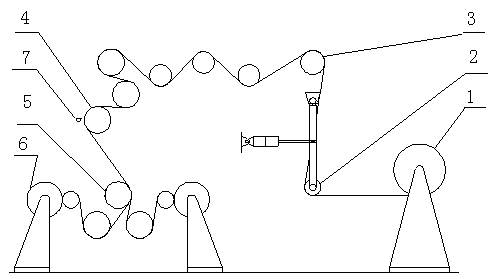

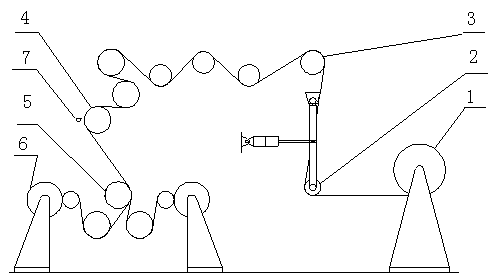

[0010] Such as figure 1 As shown, the pendulum roller 2 and the knife groove roller 4 of the existing film slitting machine are equipped with independent servo drive devices and motors, changing the past from being completely passive to active. The film is pulled, and the friction between the film and the roller is overcome, which prevents the film surface from being scratched again, prevents the film from "shaking" at the knife edge and tearing the film to cause defective products, and the appearance of the product after rewinding is greatly improved. The six transmission rollers 3 and three driving rollers 5 of the existing film slitting machine are changed from the transmission mechanism driven by a single main drive motor through a synchronous belt in the past to all the rollers respectively adding servo drives and motors to make the transmission The rollers and driving rollers have changed from the existing integral drive to independent drive. The independent drive can e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com