Seam welder electrode wheel synchronous control system and method

A synchronous control, electrode wheel technology, applied in the direction of roller electrode welding, etc., can solve the problems of decreased welding quality, inconsistent electrode wheel linear speed, etc., and achieve the effect of accurate welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention The present invention will be described in detail with reference to the accompanying drawings.

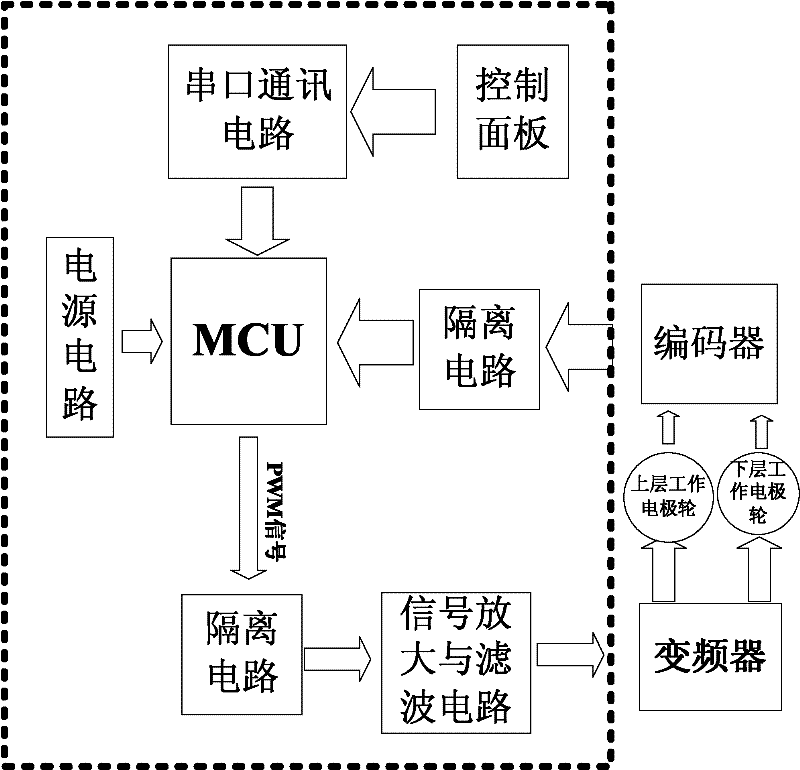

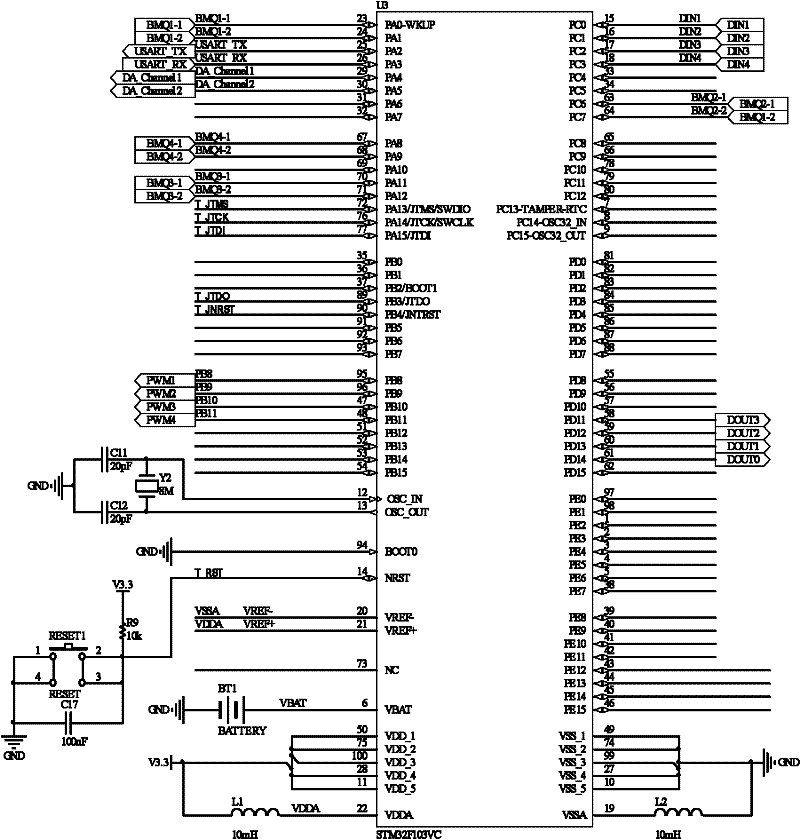

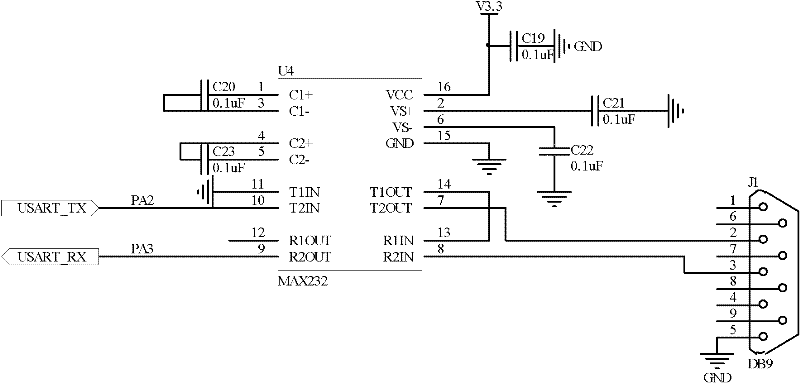

[0021] The system consists of control panel, MCU controller, working electrode wheel, encoder, frequency converter, serial communication circuit, isolation circuit, signal amplification and filter circuit, and power supply circuit.

[0022] Such as figure 1 The power supply circuit shown in the figure provides power for the entire system. Between the control signal of the MCU and the signal amplification and filtering circuit, between the encoder output signal and the MCU are realized by an isolation circuit to realize the isolation of the internal circuit and the external circuit. When the system is working, the operator sets the rotation speed of the working electrode wheel on the control panel. The control panel and the MCU controller are connected through a serial communication circuit. According to the linear relationship b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com