Noodle drying and conveying device

A conveying device and noodle technology, applied in baking, dough processing, food science, etc., to achieve the effects of high efficiency, good drying effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

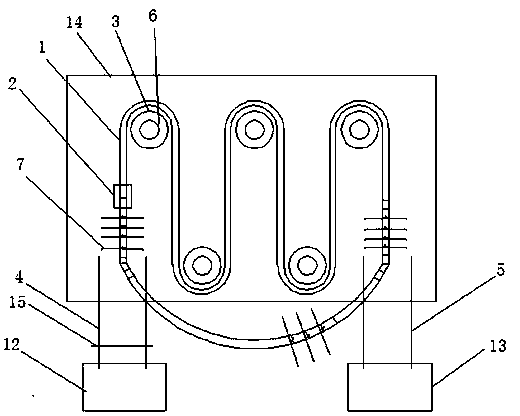

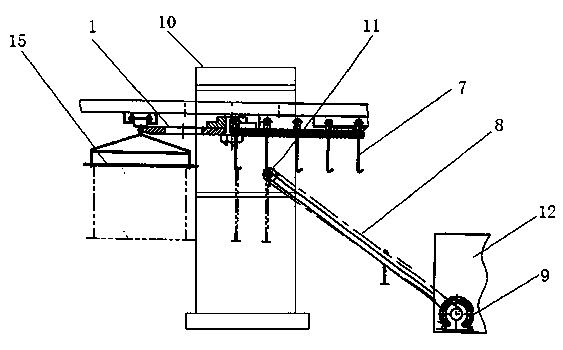

[0021] as attached figure 1 As shown, the dry noodle drying conveying device of the present embodiment includes a drying conveying chain 1, a worm gear reducer 2, a noodle stick steering mechanism 3, a noodle stick racking mechanism 4 and a noodle stick unloading mechanism 5, and the noodle stick steering mechanism 3 Drive the drying conveying chain 1 through the composite worm gear reducer 6 to turn 180°, the drying conveying chain 1 is provided with a noodle stick hook 7, and the hook of the noodle stick hook 7 faces toward the direction of movement of the noodle stick hook 7 after; as attached figure 2 As shown, the noodle pin upper rack transmission mechanism 4 includes a noodle pin upper rack conveying chain 8, a power output sprocket 9 installed on the noodle rolling and cutting host 12, a bracket 10 and a top sprocket 11 installed on the top of the bracket 10, The power output sprocket 9 is connected with the top sprocket 11 through the conveying chain 8 on the noodl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com