Pushing apparatus for packaging disposal sanitary article

A hygienic product, one-off technology, applied in the packaging, packaging, transportation and packaging of paper products, etc., can solve the problems of slow moving speed and inability to adapt to high-speed operation of the machine, uneven speed of the pusher device, and heavy weight of moving parts. The effects of fully automatic operation, weight reduction, and increased movement speed and frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

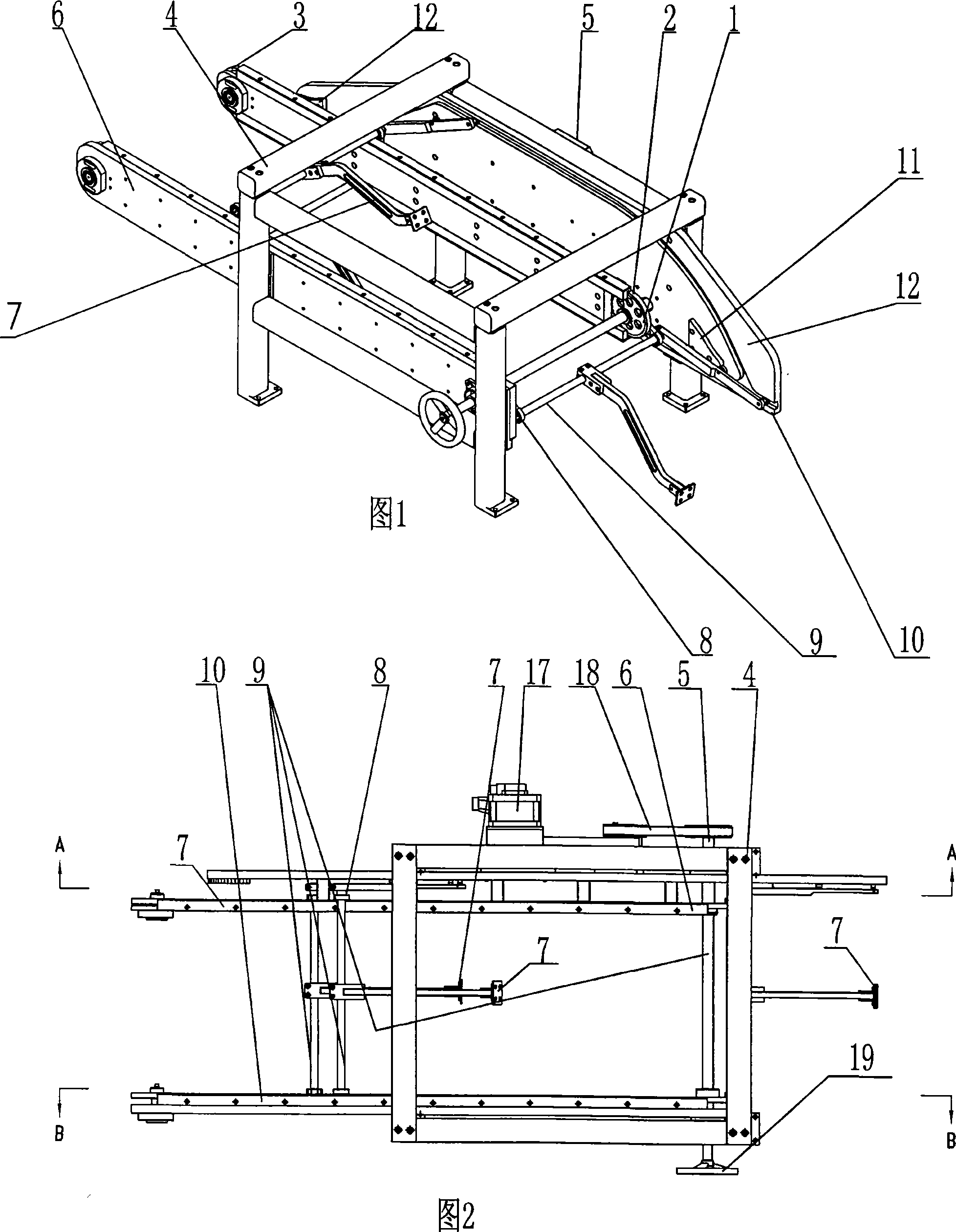

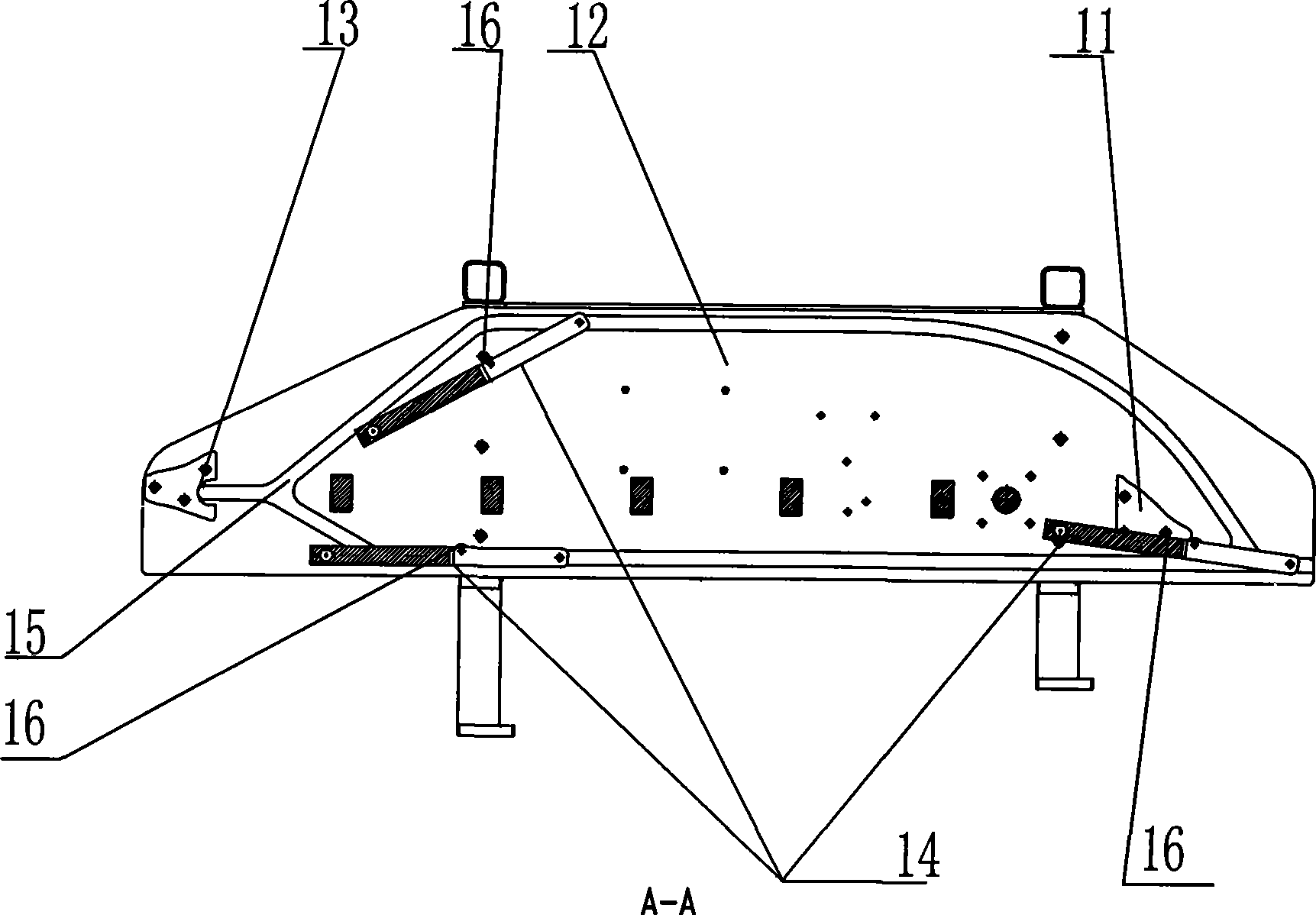

[0021] See Figure 1, Figure 2, image 3 and Figure 4 , the disposable hygienic product packaging pusher device includes a cubic frame frame 4, the left side plate 6 and the right side plate 10 are respectively fixedly installed on both sides of the frame 4, and the left side plate 6 and the right side plate 10 are parallel;

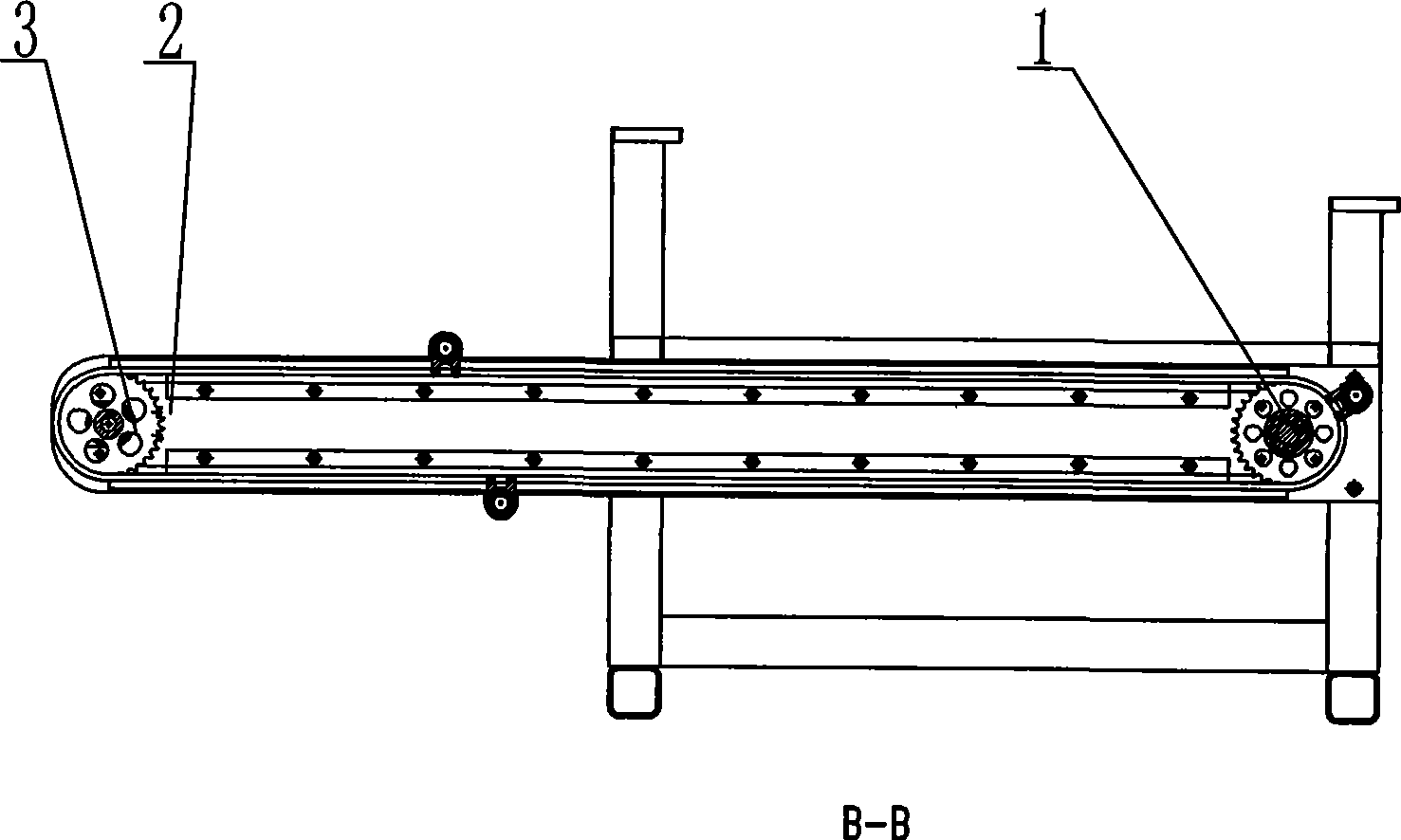

[0022] The driving wheel shaft 5 and the driven wheel shaft run through the two ends of the left side plate 6 and the right side plate 10 respectively, and the driving sprocket 1 is respectively installed on the driving wheel shaft 5 on the inner side of the left side plate 6 and the right side plate 10. Driven sprocket 3 is installed on the driven wheel axle of plate 6 and right side plate 10 inner surfaces, left chain is straddled respectively on the driving sprocket and driven sprocket of left side plate 6 inner surfaces, and right side plate 10 A right chain 2 is straddled on the driving sprocket and the driven sprocket on the side;

[0023] The two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com