Polytetrafluoroethylene-made blank pipe plane collecting device and method

A technology of polytetrafluoroethylene billet tube and polytetrafluoroethylene, which is applied in the field of plane take-up devices for polytetrafluoroethylene billet tubes, can solve the problems of low tensile, compressive and bending strength, uneven wall thickness, Unable to meet the demand and other problems, to achieve the effect of improving space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

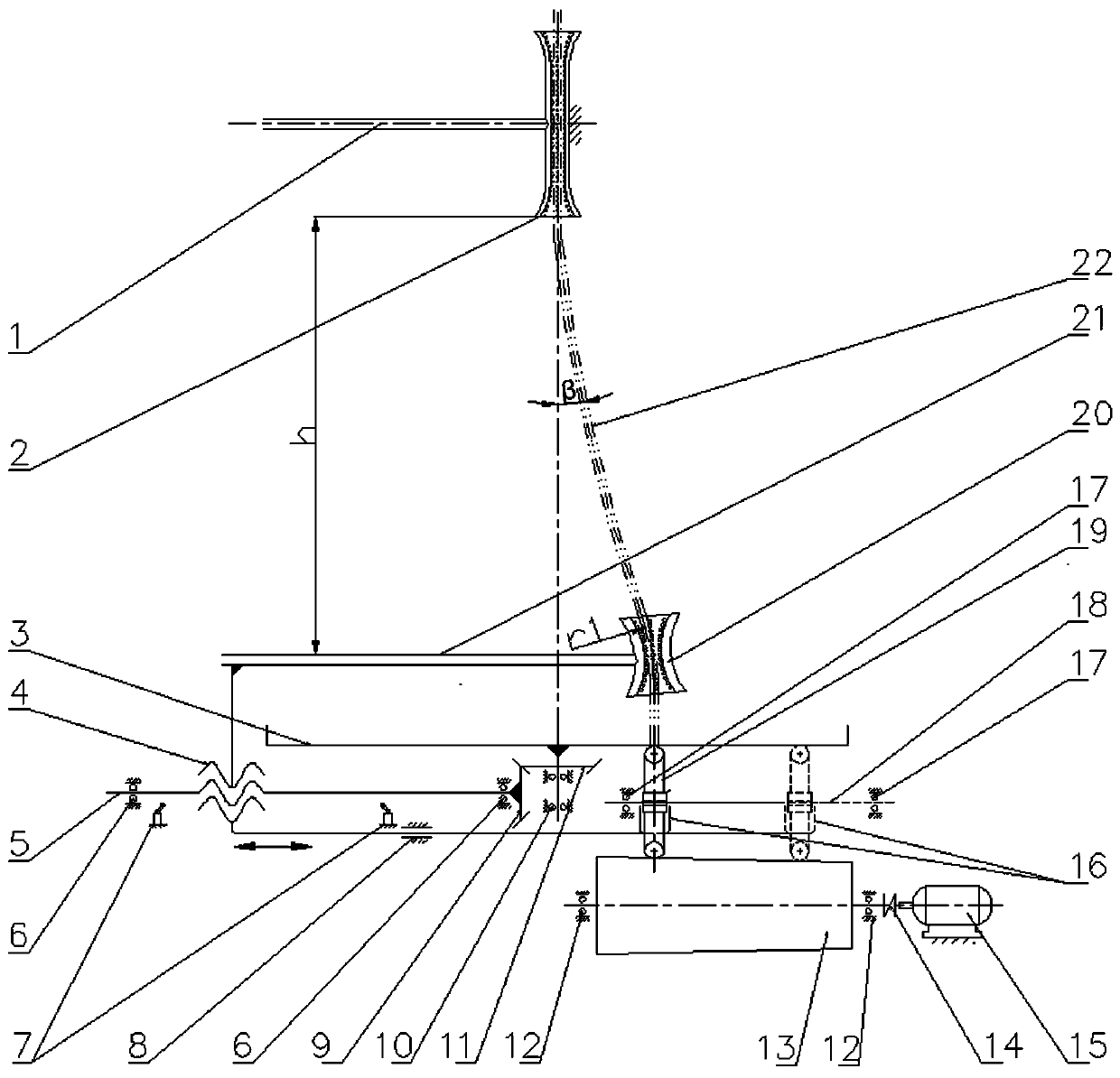

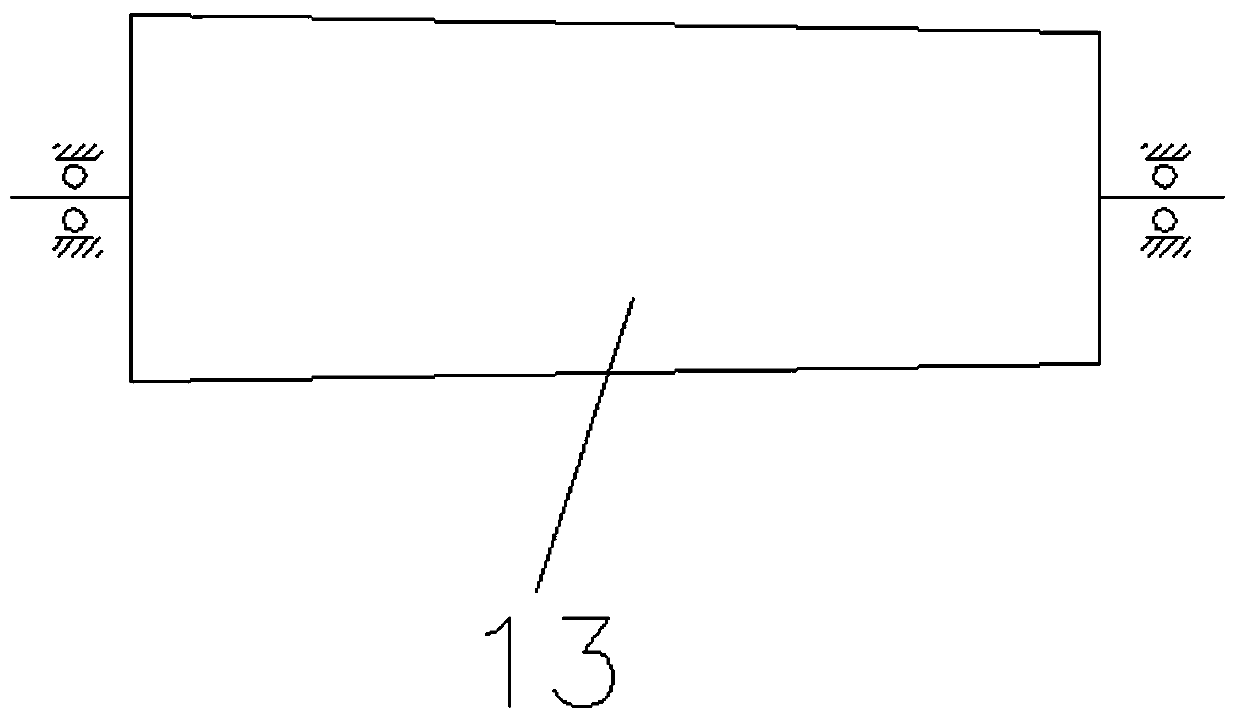

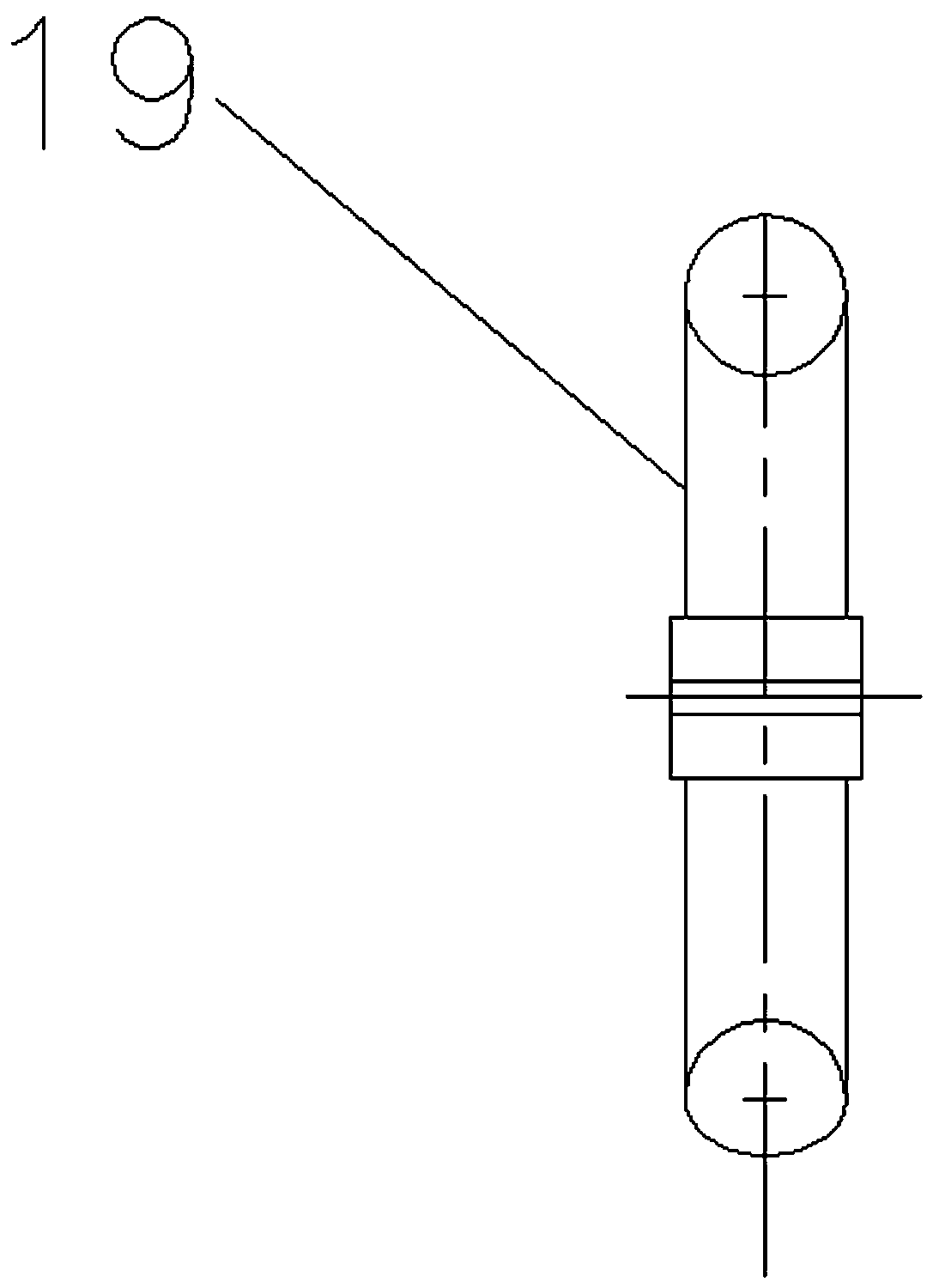

[0034] Example: such as figure 1 As shown, it includes the central air-floating guide tube 2 module arranged vertically. The lower part of the tube 2 module is provided with an air-floating wiring guide tube 20 module with the same structure as the central air-floating guiding tube 2 module. The air-floating wiring guiding tube 20 module includes the air-floating wiring guiding tube 20 and the air-floating wiring guiding tube The air intake pipe 21; the lower part of the air-floating wiring guide pipe 20 module is provided with a horizontally arranged and circular pipe collection tray 3, and a vertical shaft is fixed at the center of the bottom surface of the pipe collection tray 3, and the outside of the shaft is respectively provided with collection trays from top to bottom. Pipe reel bevel gear 11 and pipe collection reel support bearing 10, pipe collection reel bevel gear 11 is fixedly connected with the rotating shaft, pipe collection reel 3, rotating shaft, pipe collecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com