Metal piece, machining method for surface veins of metal piece and electronic equipment

A technology of surface texture and processing method, applied in the field of metal parts processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

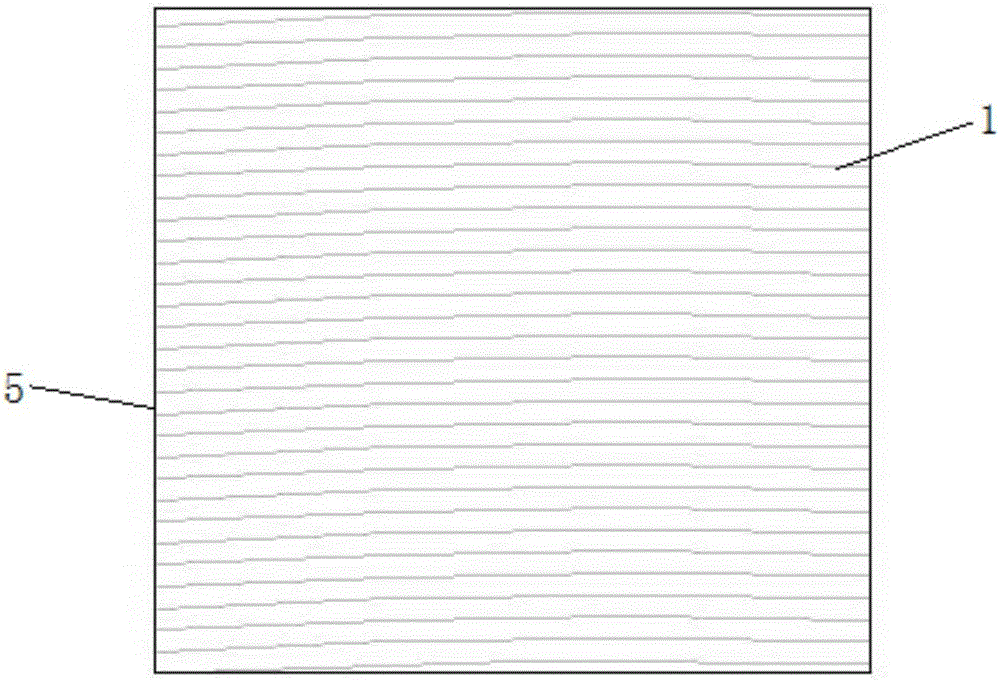

[0030] refer to figure 1 , In this embodiment, a metal piece 5 is provided, the surface of the metal piece 5 has a texture. Wherein, the texture includes a plurality of spaced strip corrugations 1, and each strip corrugation 1 is arc-shaped as a whole and the plurality of strip corrugations 1 protrude toward the same direction, or each strip corrugation 1 is linear in shape and multiple The strip corrugations are 1 parallel. Also, as is known, the corrugations consist of alternately arranged grooves and protrusions.

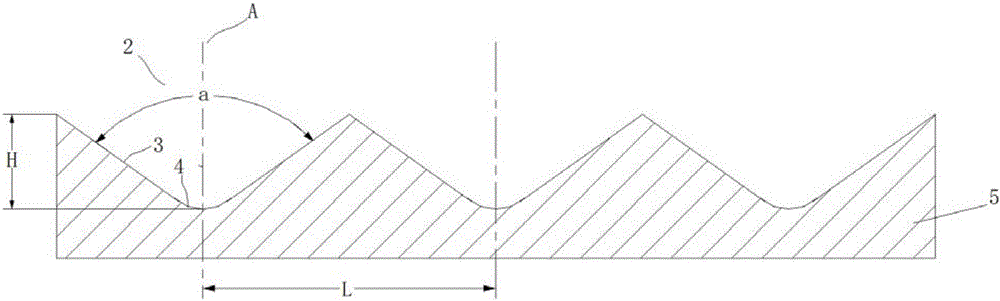

[0031] to combine figure 1 and figure 2 , in this embodiment, each strip corrugation 1 includes a plurality of grooves 2, and each groove 2 includes two opposite first slopes 3 and a first circle connecting the bottom ends of the two first slopes 3 The arc surface 4, the two first slopes 3 and the first arc surface 4 are symmetrically arranged with respect to the vertical center plane A of the groove 2, and the horizontal distance between the two first slope...

Embodiment 2

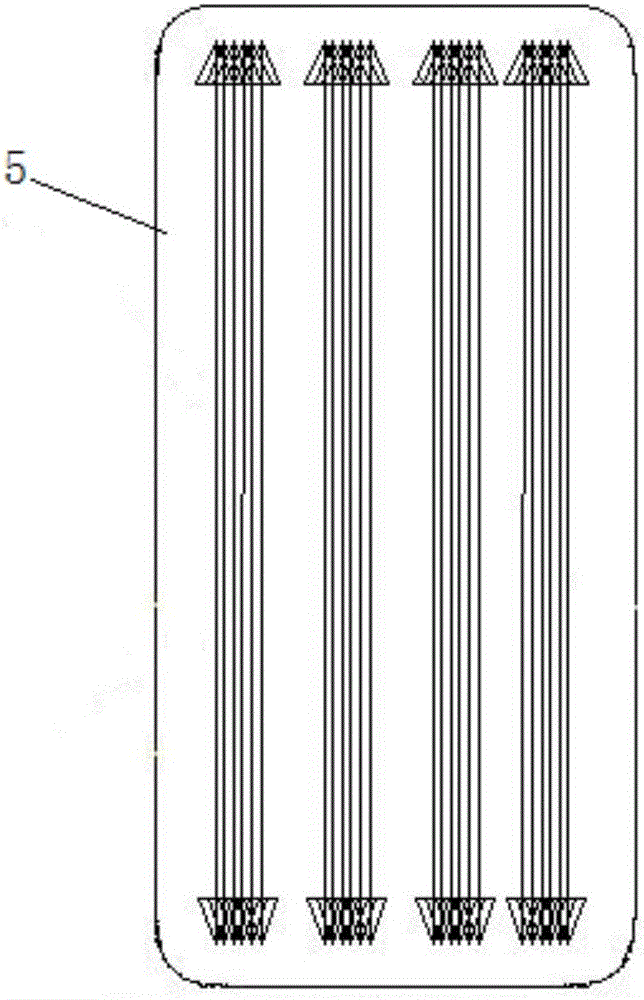

[0037] refer to Figure 4 to Figure 6 , in this embodiment, a method for processing the surface texture of the metal part for processing the metal part 5 in the first embodiment is provided. The metal surface texture processing method comprises the following steps:

[0038] S1, rough machining the surface of the metal part 5;

[0039] S2, finishing the surface of the metal part 5, processing the surface into a flat bright surface;

[0040] S3, the workbench 6 that is fixed with a plurality of metal pieces 5 rotates around its rotation center o (each metal piece 5 all does the revolution around the rotation center o of the workbench 6), and simultaneously the cutter 7 moves up and down on each metal piece An arc-shaped strip corrugation 1 is processed on the surface of 5, wherein a plurality of metal parts 5 are symmetrically arranged around the rotation center o, and the cutter 7 only moves up and down without rotation and revolution;

[0041] S4. The workbench 6 moves horizo...

Embodiment 3

[0052] In this embodiment, an electronic device is provided. The electronic device includes the metal part 5 of the first embodiment above, and the metal part 5 is a metal casing of the electronic device. The surface of the electronic device forms an appearance effect with bright vertical lines, and as the viewing angle changes, the bright vertical lines also change accordingly, thereby improving the fineness of the surface of the electronic device.

[0053] Preferably, the electronic device can be a mobile phone, a tablet computer and the like.

[0054] Preferably, the metal part 5 is an aluminum alloy battery cover of a mobile phone. Both sides of the aluminum alloy battery cover include curved surfaces. The above-mentioned texture can extend to the curved surface area to ensure the consistency of the overall surface effect of the aluminum alloy battery cover and improve the fineness of appearance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com