Optical cable production equipment and system

A technology for production equipment and production systems, applied in the directions of light guides, optics, optical components, etc., can solve the problems of difficult to guarantee the distribution position of the reinforcement, uneven distribution of the strength of the optical cable, unstable quality of the optical cable, etc., to achieve uniform distribution of traction force, tensile strength Ability to highlight, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

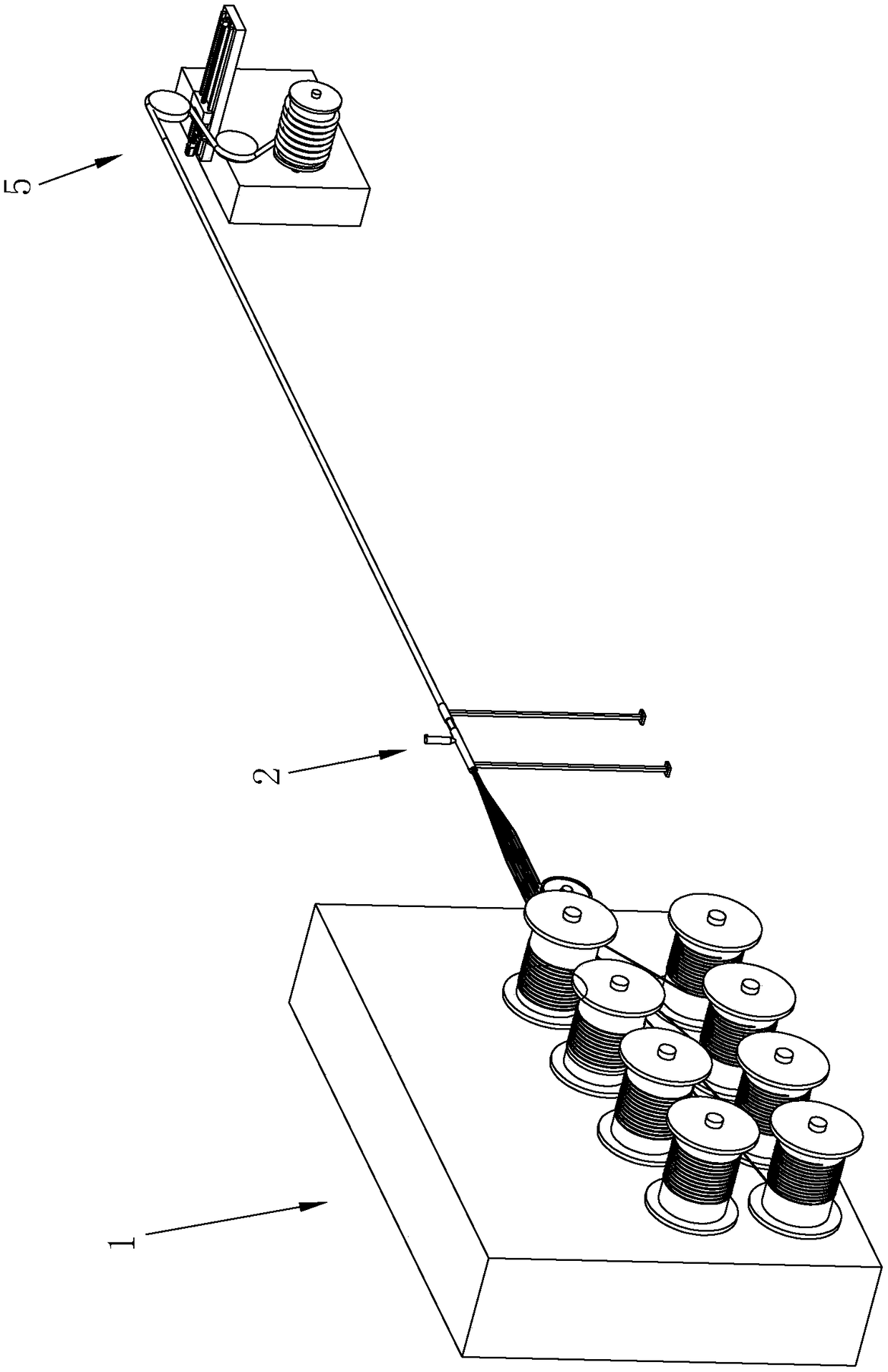

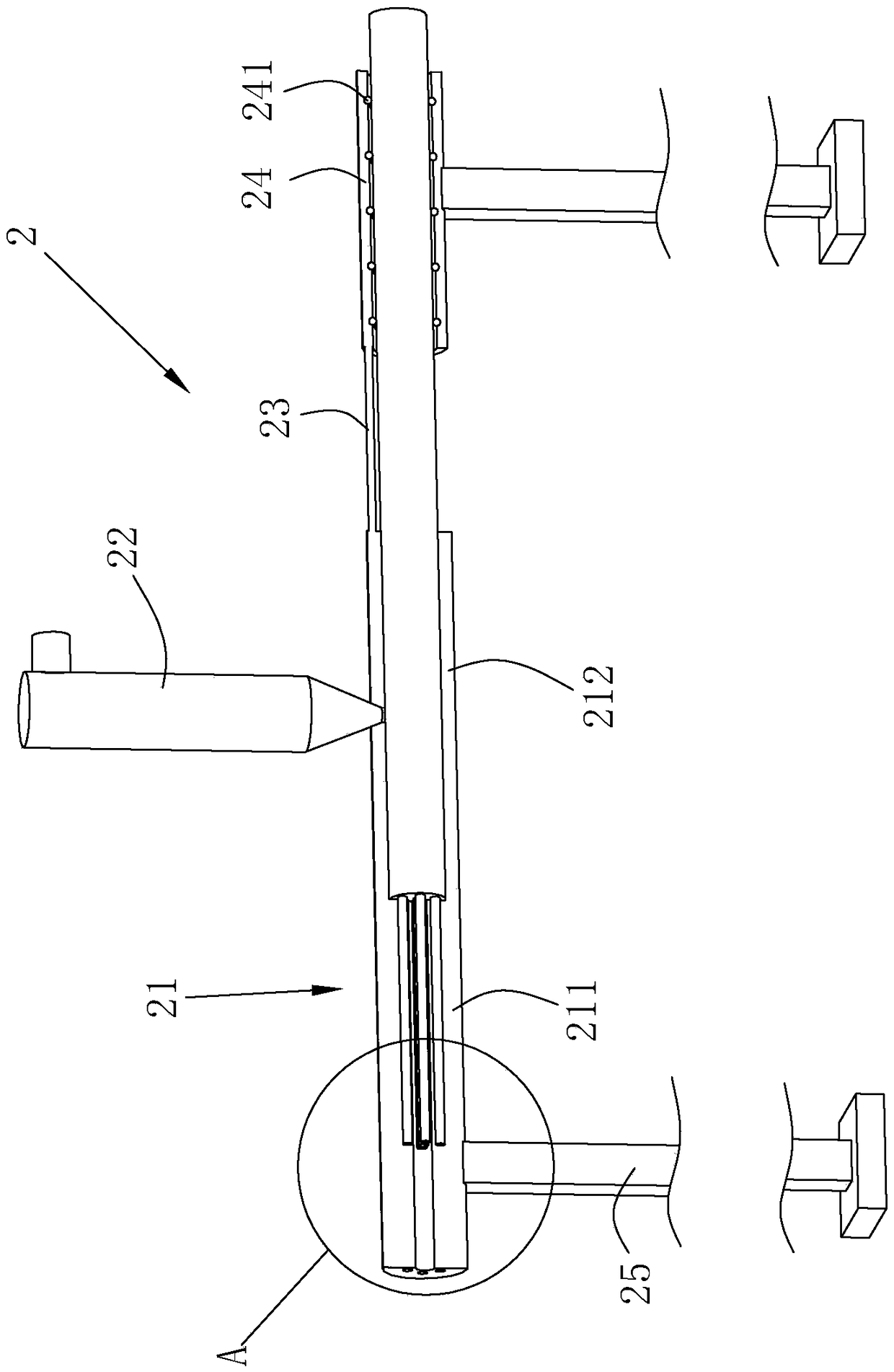

[0047] A kind of optical cable production equipment, refer to figure 1 , including an unwinding device 1, an extruding device 2 and a winding device 5 arranged in sequence, wherein the unwinding device 1 is used to guide the optical fiber and strengthen the strength of the optical cable, and the extruding device 2 is used to extrude the protective material To wrap optical fibers and strength members.

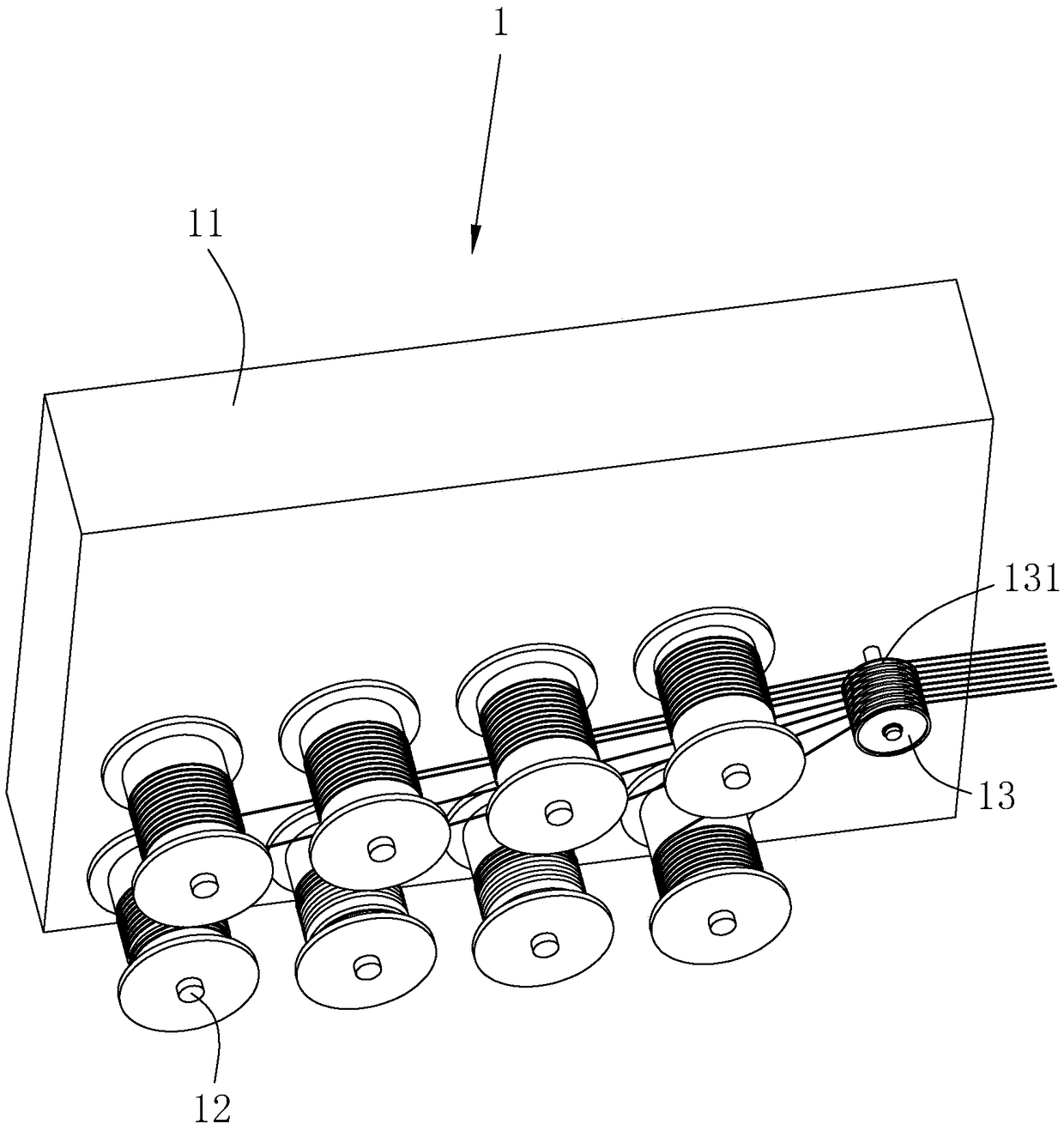

[0048] refer to figure 2 , the guiding device 1 comprises a guiding seat 11, on which the guiding seat 11 is rotatably connected with several rotating shafts 12 parallel to each other. Sleeved on the rotating shaft 12 to follow the rotating shaft 12 to rotate, the guide seat 11 is connected with a damping plate (not shown) abutting on the rotating shaft 12 .

[0049] The guide device 1 also includes a guide wheel 13 that is rotatably connected to the guide seat 11, the axis of rotation of the guide wheel 13 is parallel to the axis of the rotating shaft 12, and the sidewall of...

Embodiment 2

[0067] A kind of optical cable production system, refer to Image 6 , including the unwinding device 1, the extruding device 2, the tensioning device 4 and the rewinding device 5 arranged in sequence, the optical cable enters the rewinding device 5 after passing through the tensioning device 4, wherein the unwinding device 1, the extruding device 2 and the rewinding device 5 The winding device 5 is the unwinding device 1 , the extruding device 2 and the winding device 5 in the first embodiment.

[0068] refer to Figure 8 , the tensioning device 4 includes a tensioning support 41, and the tensioning support 41 is rotatably connected with a front roller 421 and a rear roller 431. There are two pairs of front rollers 421, and each pair of front rollers 421 is opposite to each other along the radial direction of the optical cable. The front rollers 421 are evenly distributed around the circumference of the optical cable to form a front roller group 42, and there are two pairs of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com