Novel wear-resistant and high-temperature-resistant rubber roller

A rubber roller, high-resistant technology, applied in the direction of rubber layered products, layered products, shafts and bearings, etc., can solve the problem of single performance, short service life, inability to combine high toughness, high elasticity, wear resistance, heat resistance, etc. problems, to achieve long service life, outstanding tensile strength and crack resistance, good wear resistance and heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

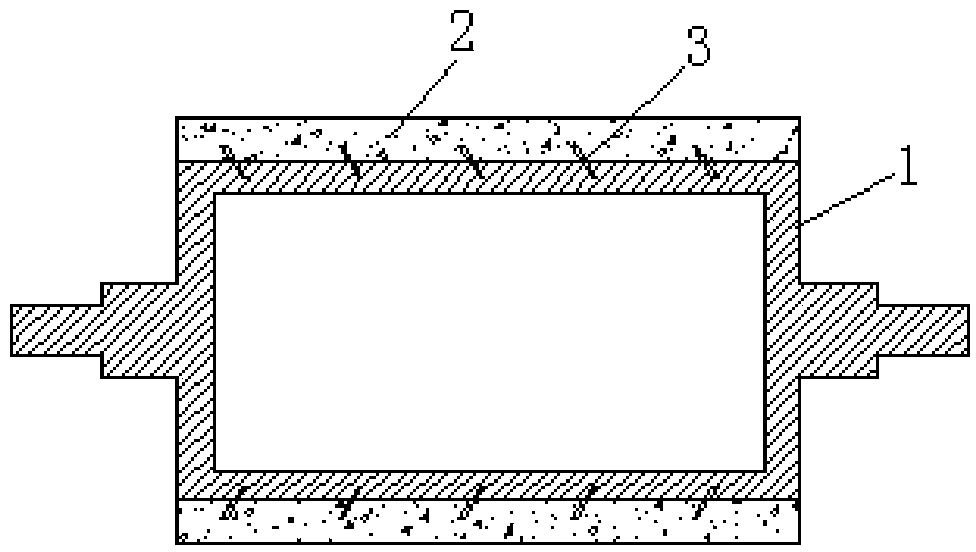

[0013] Referring to the accompanying drawings, a new wear-resistant and high-resistant rubber roller includes a rubber roller body 1 and a rotating shaft 2 arranged in the rubber roller body, and the outer surface of the rotating shaft is provided with a sandblasting layer. The rubber roller body is covered with a polyurethane rubber layer, and a plurality of steel wire sheets 3 are arranged between the polyurethane rubber layer and the rubber roller body, and the plurality of steel wire sheets are evenly distributed on the rotating shaft, and the thickness of the polyurethane rubber layer is 0.5 -1.5mm, the rubber roller body is chlorosulfonated polyethylene rubber, and the surface roughness of the rubber roller body is 2.0um~15.0um.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com