Royal noodle drawing and coiling machine

A technology of dough plate and palace noodles, which is applied in the directions of dough extruder, dough processing, baking, etc., can solve the problem of low efficiency of dough stretching, and achieve the effect of improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

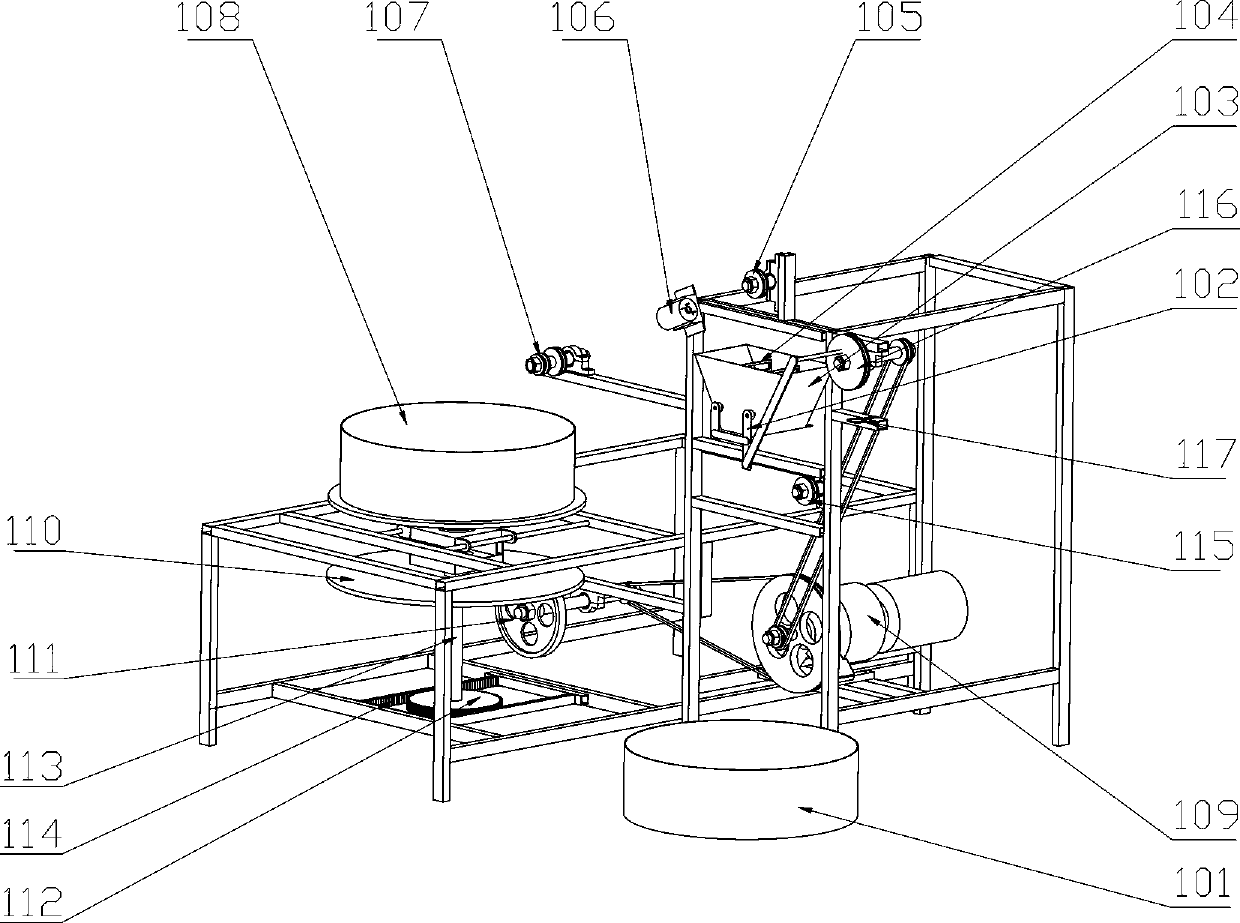

[0020] as attached Figure 1-4 As shown, the main structure of the palace noodle stretched noodle wire rod machine is a tray 101, a conveying system, a stretched noodle system, and a wire rod system. Conveyor system comprises transmission wheel A 105, transmission wheel B 107, transmission wheel C 115, transmission wheel D 116, guide ring 117, is mainly responsible for the conveying of noodles during processing.

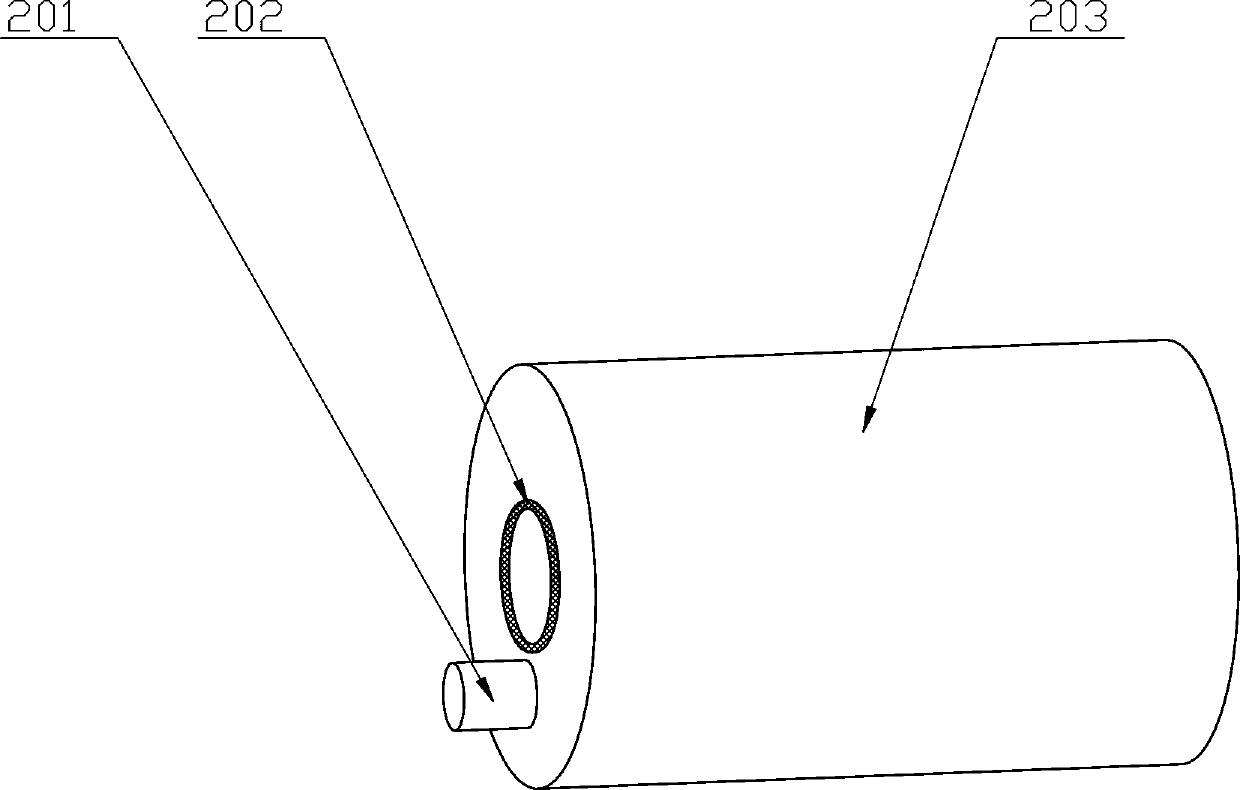

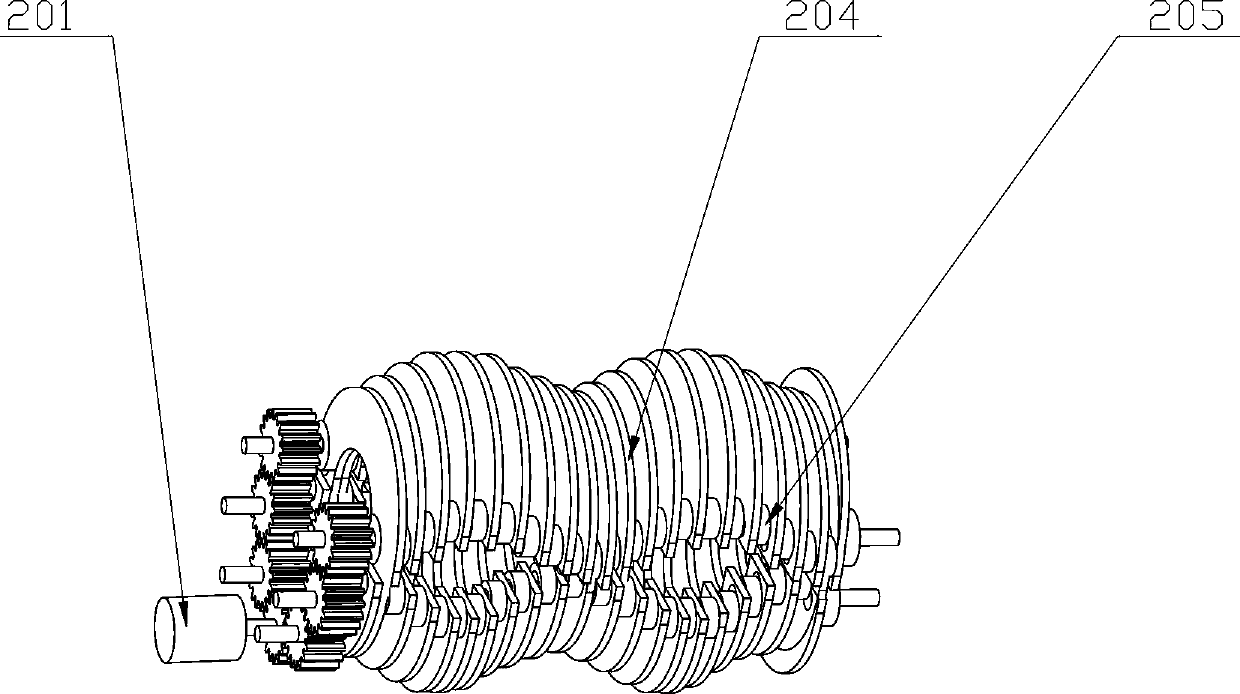

[0021] The noodle stretching system is provided with a noodle stretcher 106, the outside of which is a casing 203, the motor 201 is installed outside the casing 203, and the inside of the casing 203 has a meniscus group and a driving device for driving the movement of the meniscus group. The meniscus group includes the upper meniscus group and the lower meniscus group. The upper half moon group includes several menisci 205 and spacers 206, the spacers 206 are used for axial positioning between two adjacent menisci 205, the lower meniscus group is located under the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com