Straightening machine

A straightening machine and straightening roller technology, applied in the field of straightening machines, can solve the problems of small straightening range, inability to produce aluminum plates with different thickness requirements, etc., and achieve the effects of convenient and fast operation, good straightening effect and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Further detailed explanation through specific implementation mode below:

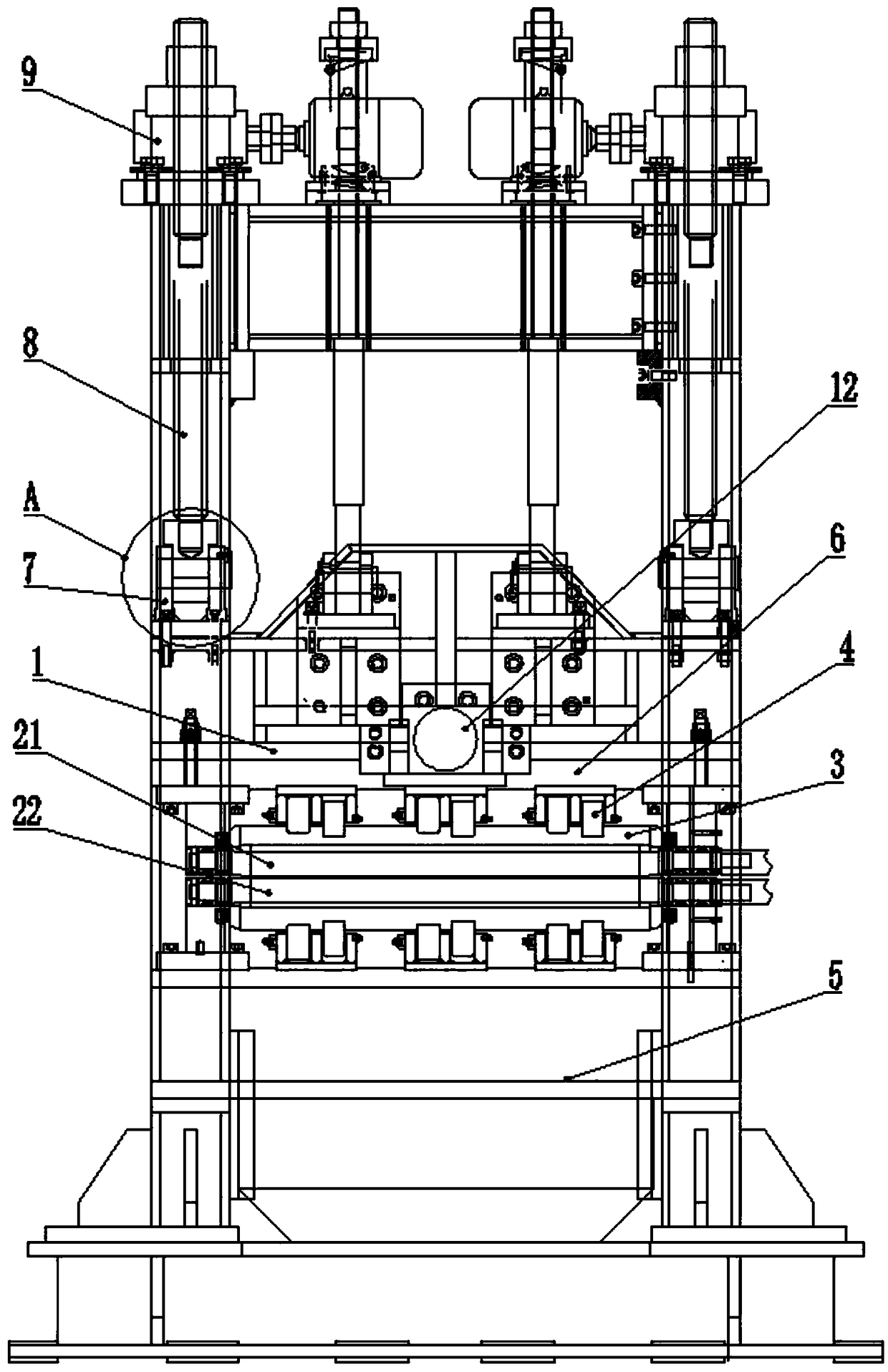

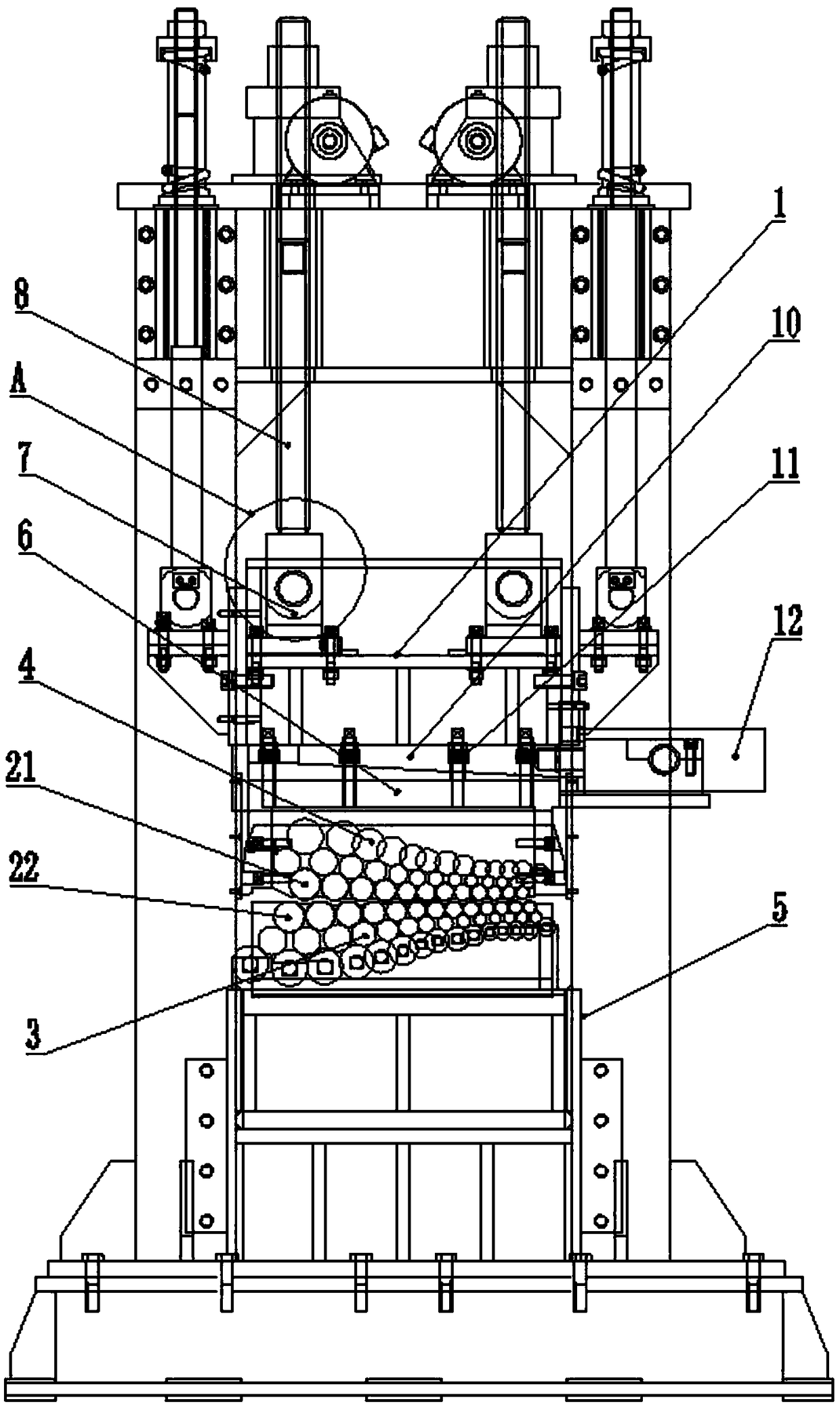

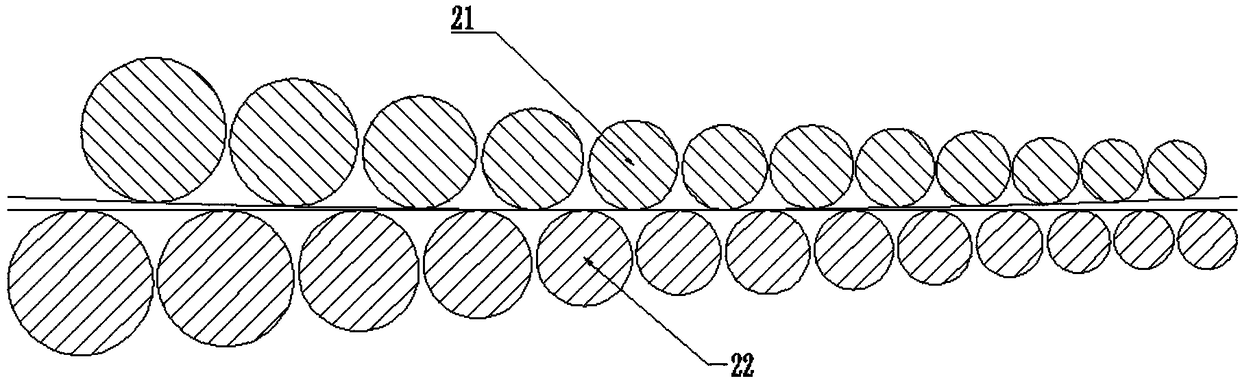

[0022]The reference signs in the drawings of the description include: upper frame 1, upper straightening roller 21, lower straightening roller 22, intermediate roller 3, support roller 4, lower frame 5, support frame 6, reversing seat 7, support Ear 71, pin shaft 72, positioning bolt 73, clamping plate 74, leading screw 8, gearbox 9, inclined slide plate 10, disc spring 11, oil cylinder 12.

[0023] The embodiment is basically as attached figure 1 , figure 2 Shown: a straightening machine, including an upper frame 1 and a lower frame 5, the upper frame 1 is provided with an upper roller system, the lower frame 5 is provided with a lower roller system, and the upper roller system includes an upper straightening roller 21, the lower roll system includes the lower straightening roll 22, combined with image 3 Shown, the lower straightening roller 22 has a plurality of side by side horizontally a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com