High-gloss three-dimensional gilding method

A high-gloss, three-dimensional technology, applied in the direction of temperature recording method, printing, printing device, etc., can solve the problems of weak substrate adhesion, long process time, inability to apply, etc., to save the waiting time for drying, efficient and continuous. The effect of bronzing and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

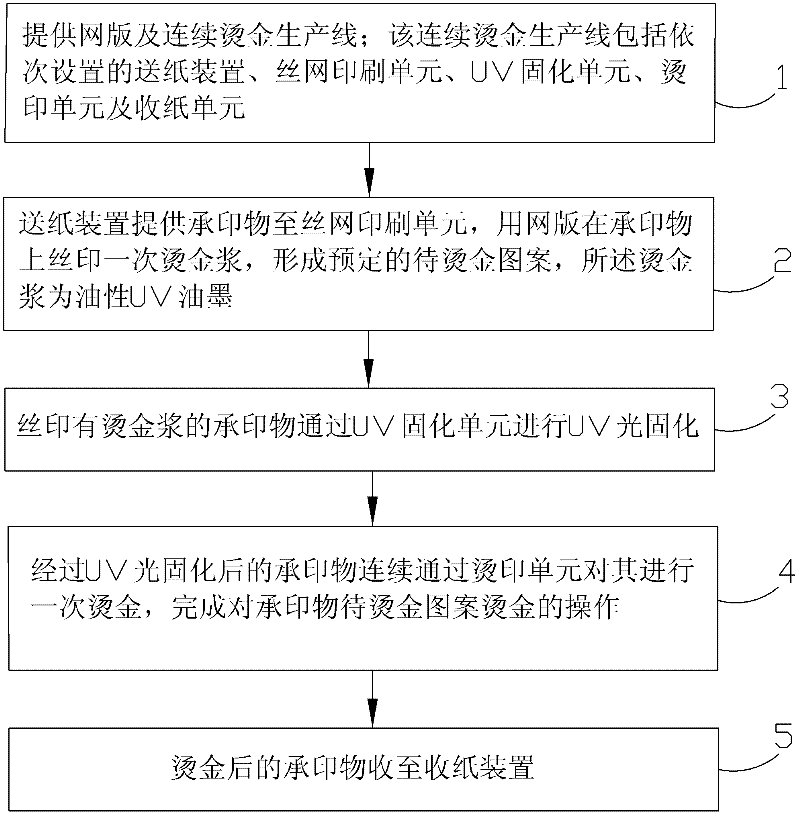

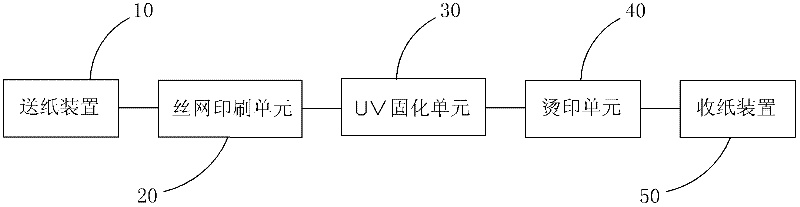

[0027] see figure 1 , the high-gloss three-dimensional bronzing method of the present invention comprises the following steps:

[0028] Step 1. Provide a continuous production line for screen printing and bronzing; the screen is made of nylon mesh by stretching, preferably 18T-40T nylon mesh to make the desired screen. The screen plate is coated with photosensitive paste, and is baked and exposed by a printing machine. The photosensitive paste can adopt existing traditional photosensitive paste or special thick-plate photosensitive paste, preferably thick-plate photosensitive paste. The thick-plate photosensitive paste has a higher concentration than traditional photosensitive paste, and its adhesion and other performance indicators Both are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com