Patents

Literature

37results about How to "Good anti-counterfeiting function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

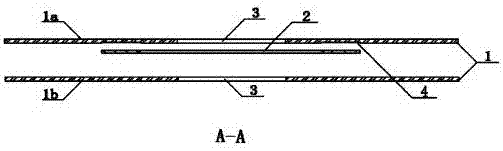

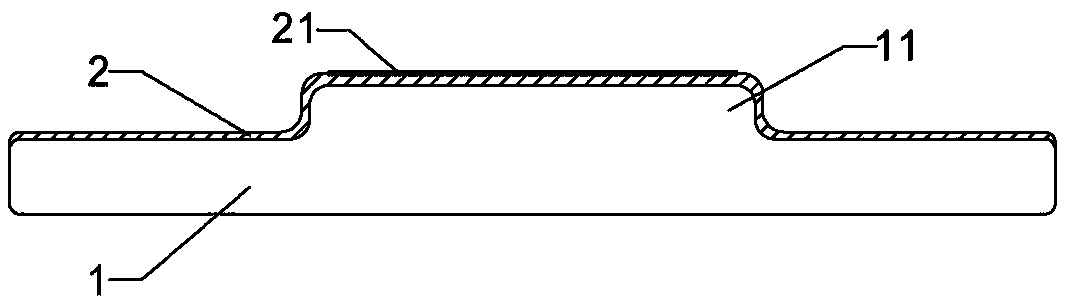

Uncovered anti-shifting paper laser anti-counterfeit label and preparation method thereof

ActiveCN103440818ANot easy to counterfeitImprove anti-counterfeiting functionStampsIdentification meansAdhesive glueEngineering

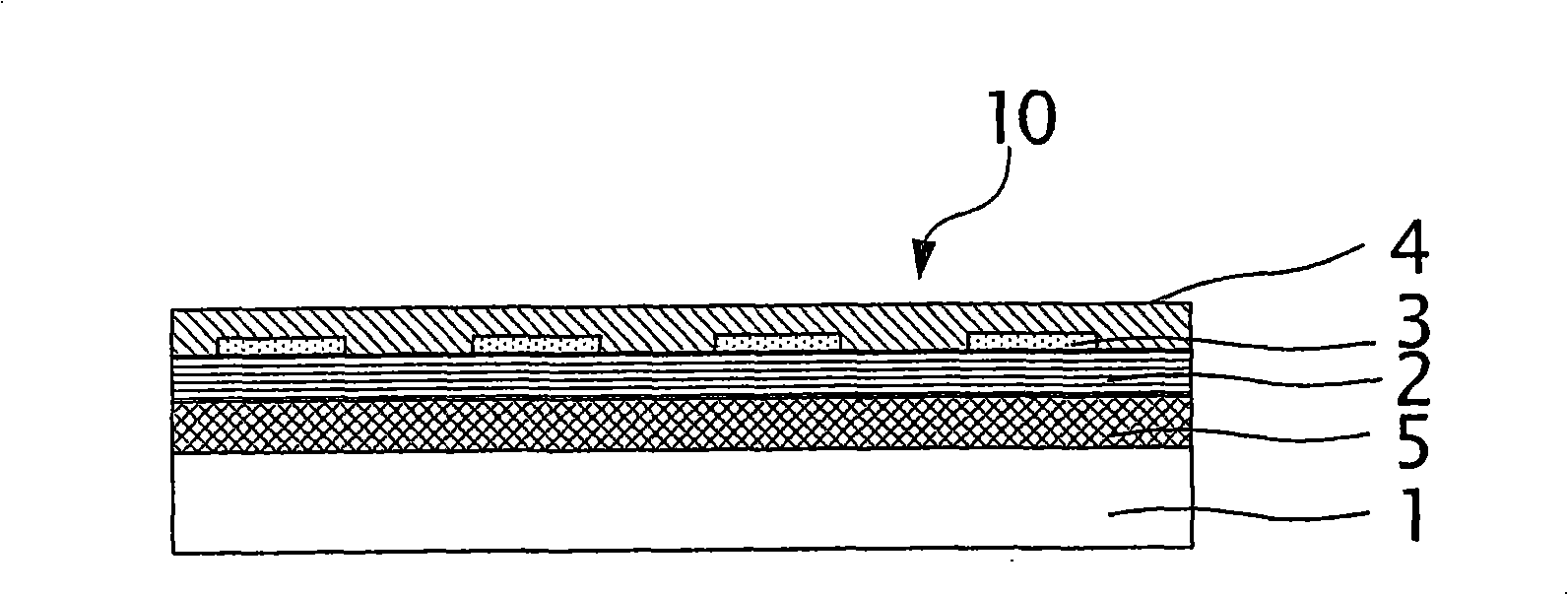

The invention relates to an uncovered anti-shifting paper laser anti-counterfeit label and a preparation method thereof. The laser anti-counterfeit label comprises a surface printed layer, a plasticized layer, data printed layers, a glue layer and a bottom paper layer. The laser anti-counterfeit label is characterized in that the data printed layers include a first data printed layer and a second data printed layer. A first water-based gloss oil layer is arranged on the upper surface of the surface printed layer, the first data printed layer is positioned on the first water-based gloss oil layer, and an oil-based gloss oil layer, a cover layer and a caption layer are sequentially arranged on the upper surface of the first data printed layer. A rainbow laser paper layer is arranged beneath the surface printed layer; the plasticized layer is arranged beneath the rainbow laser paper layer; an isolation layer and a second water-based gloss oil layer are sequentially arranged beneath the plasticized layer; the second data printed layer is positioned beneath the second water-based gloss oil layer. A white oil ink layer is arranged beneath the second data printed layer; the glue layer is positioned beneath the white oil ink layer; the bottom paper layer is positioned beneath the glue layer and is externally provided with a black ink layer. The laser anti-counterfeit label not only has multiple anti-counterfeit functions and a good anti-counterfeit effect, can not be counterfeited by counterfeiters easily and is attractive in appearance.

Owner:无锡新光印防伪技术有限公司

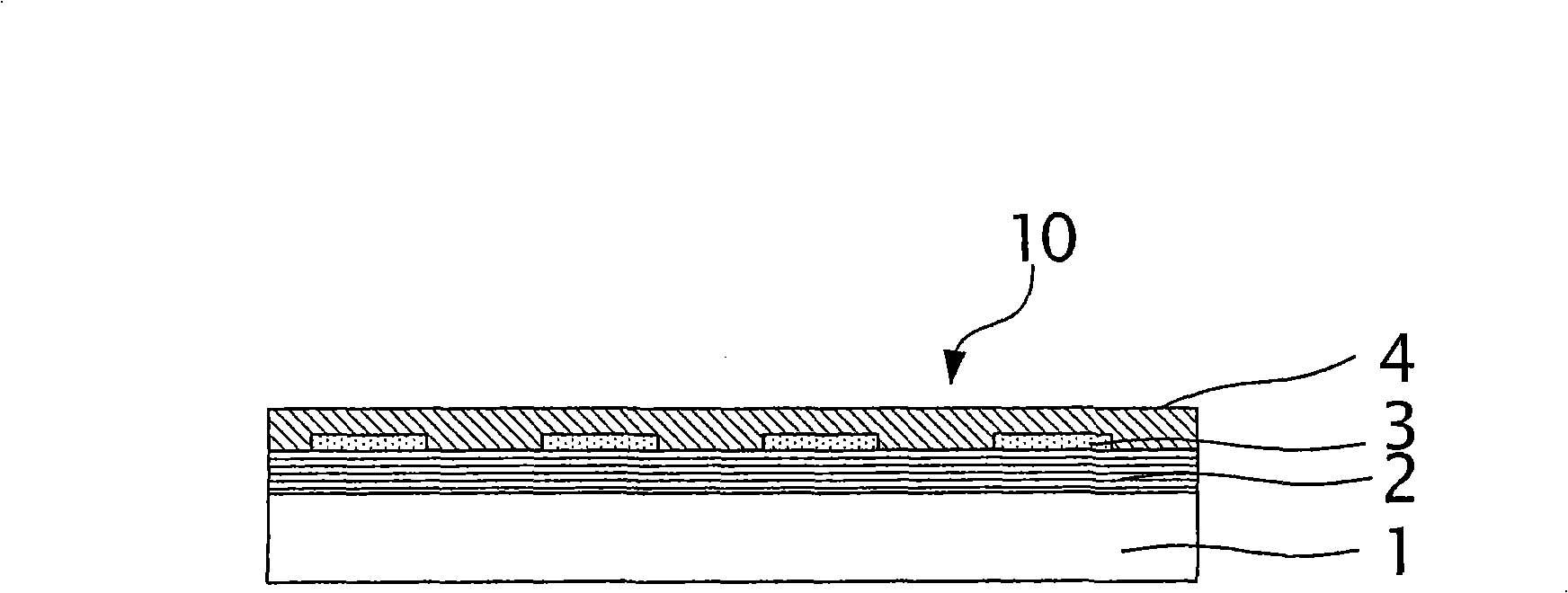

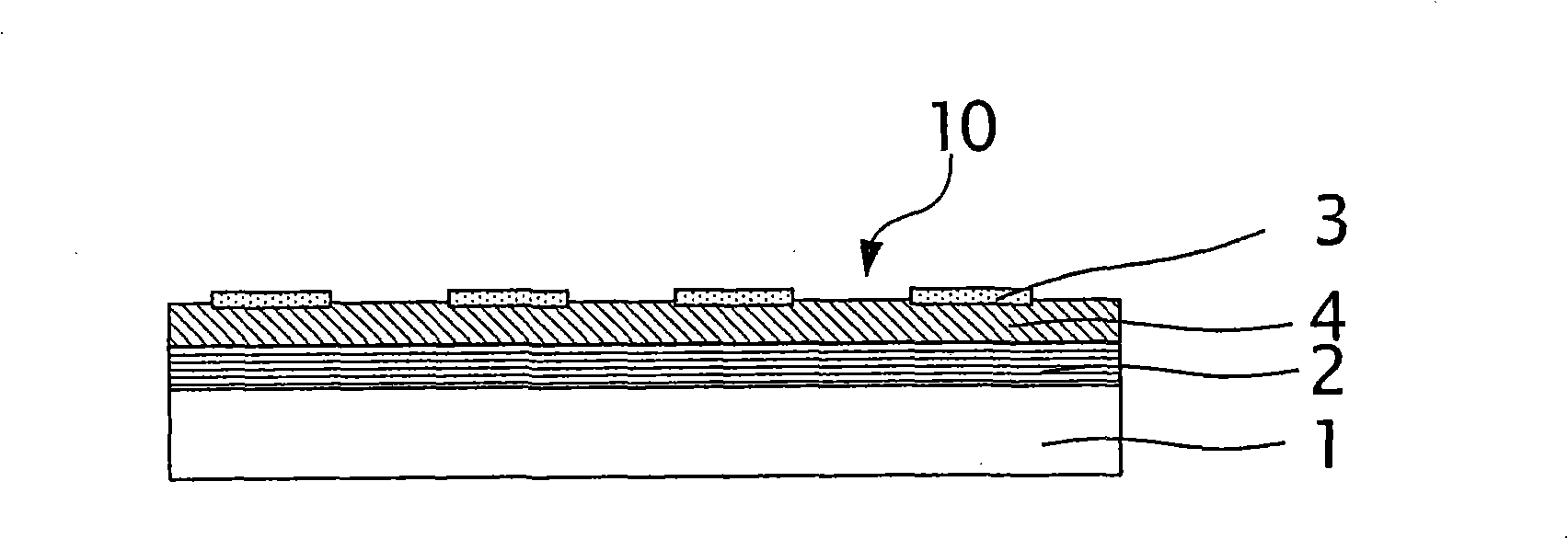

Volume hologram transfer foil, volume hologram laminate, and production method thereof

ActiveCN101329546AEasy to identifyLow costDecorative surface effectsInstrumentsImage formationReflective layer

A major object of the present invention is to provide a volume hologram transfer foil that gives a volume hologram laminate higher in antiforgery function. The present invention is characterized by comprising: a substrate, a volume hologram layer carrying a recorded volume hologram that is formed on the substrate, and an image forming layer carrying a formed image and a heat seal layer containing a thermoplastic resin that are formed on the volume hologram layer, and comprising no reflective layer having a function to reflect light. The subject can be solved by the volume hologram transfer foil provided by the present invention.

Owner:DAI NIPPON PRINTING CO LTD

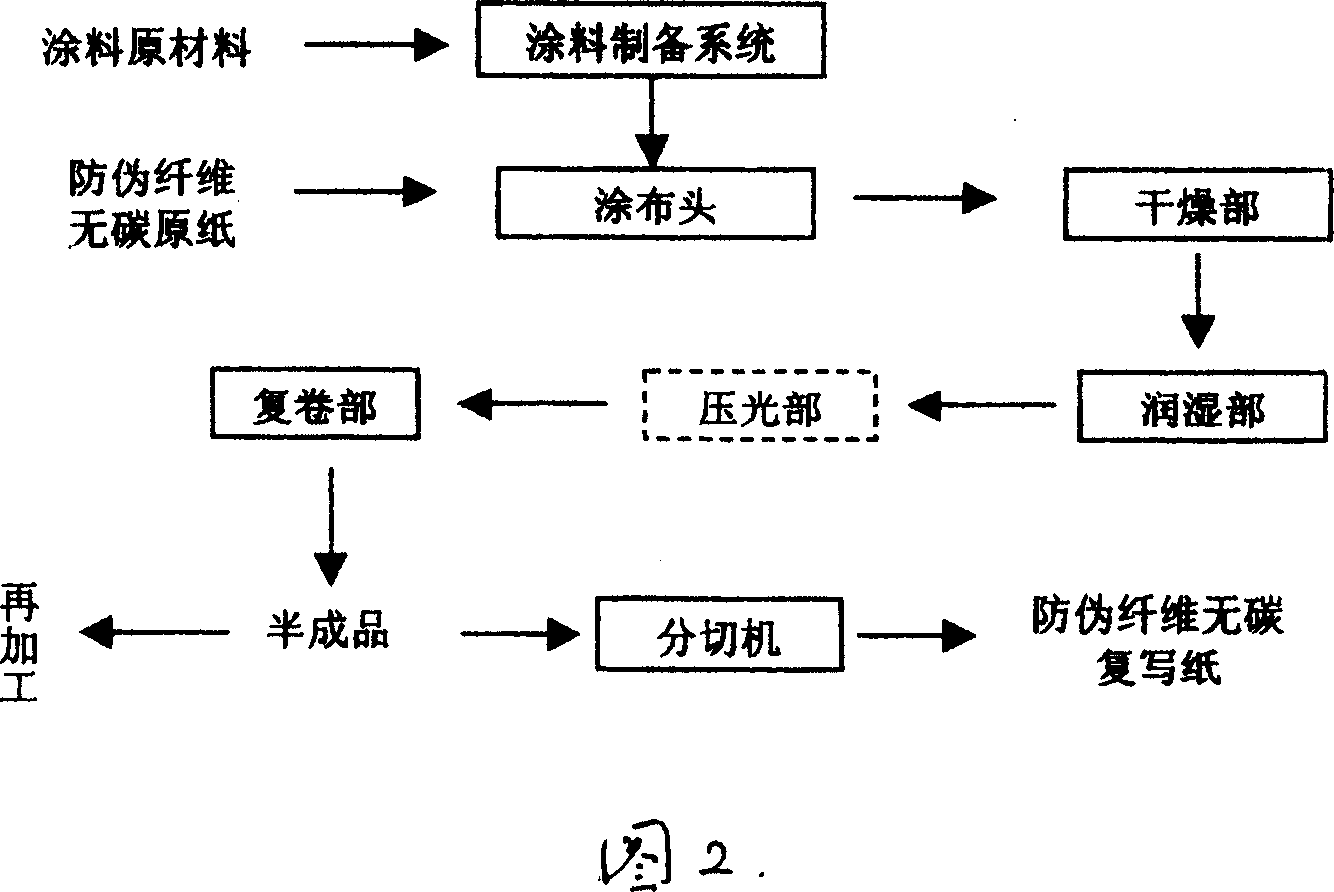

Anticounterfeit fiber carbor-free copy paper and its production method

ActiveCN1580396AGood anti-counterfeiting functionImprove yieldSpecial paperPaper coatingFiberPulp and paper industry

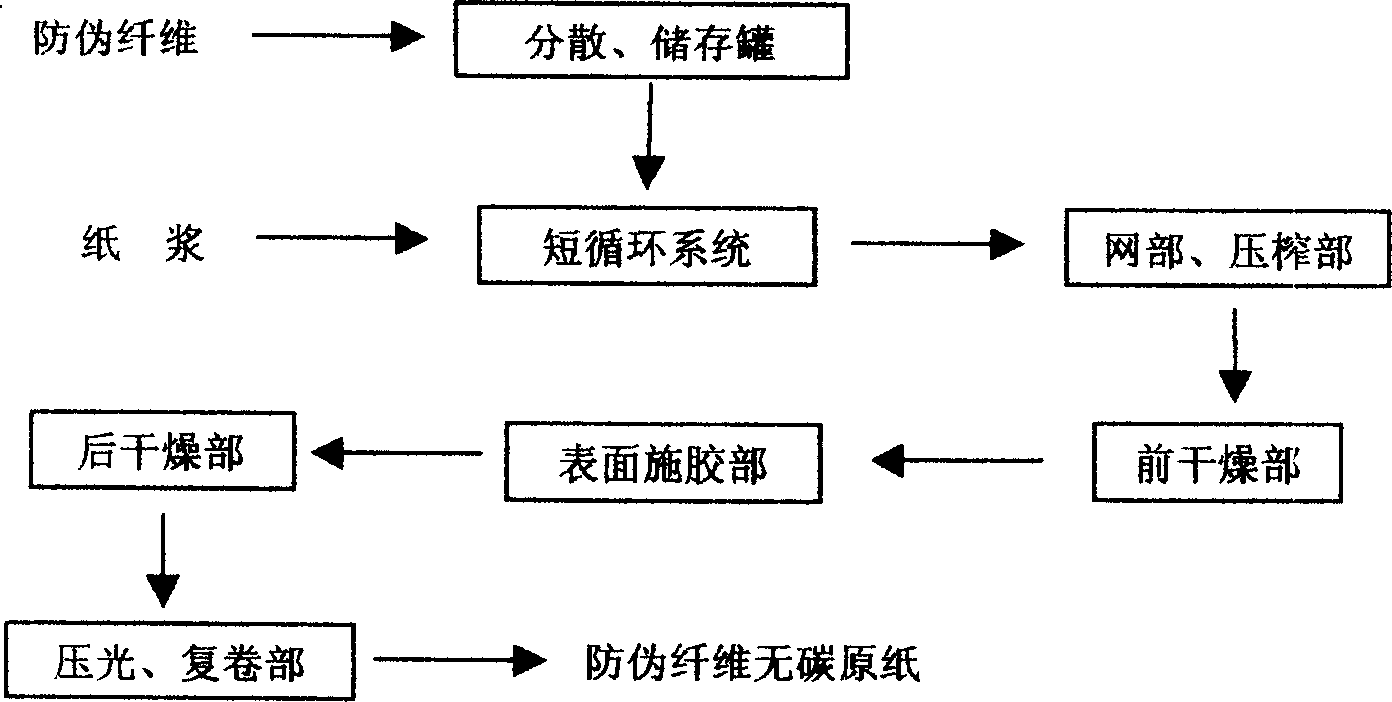

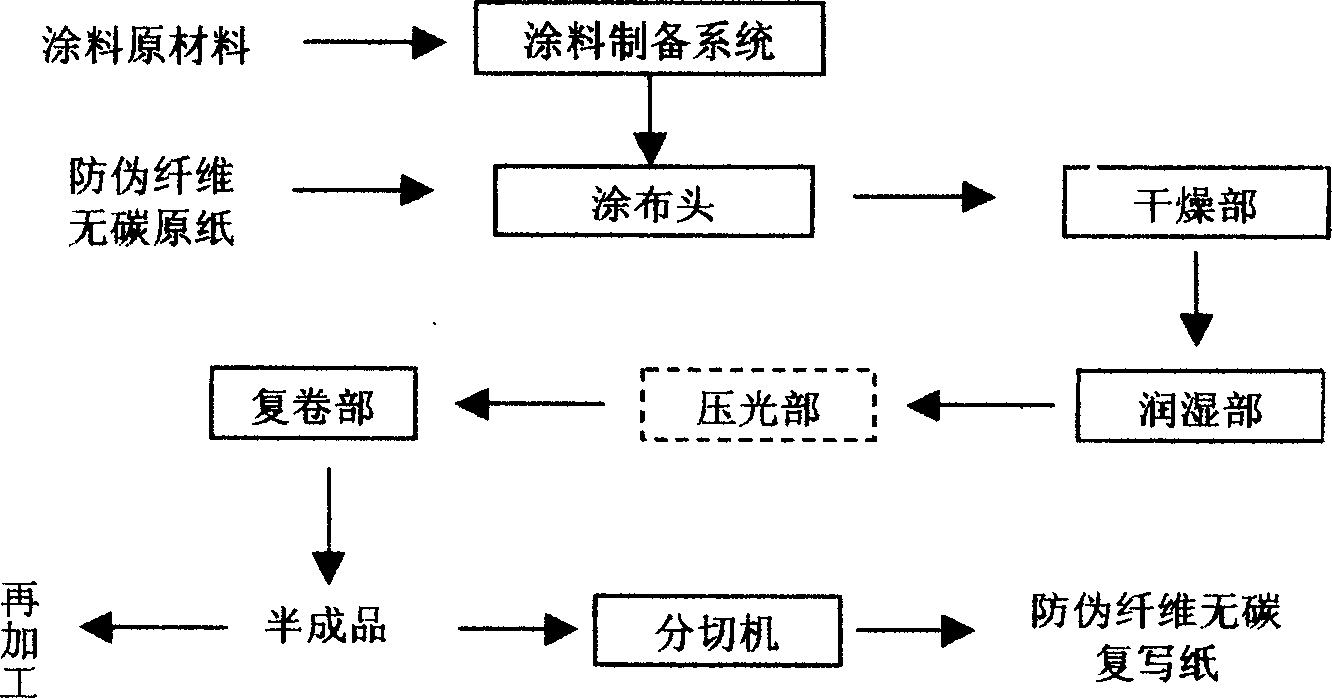

This invention relates to an anti-false fiber noncarbon paper and its production method aiming at overcoming the shortcoming of not anti-false of the current bills made of carbon copy paper which is made by adding a certain quantites of anti-false fiber original paper to produce primary anti-false then to be specially coated to produce the noncarbon paper with anti-false function.

Owner:GUANGDONG GUANHAO HIGH TECH

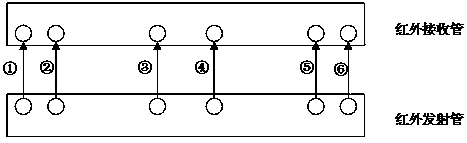

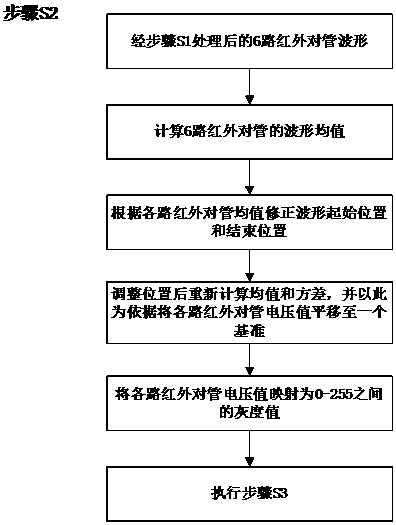

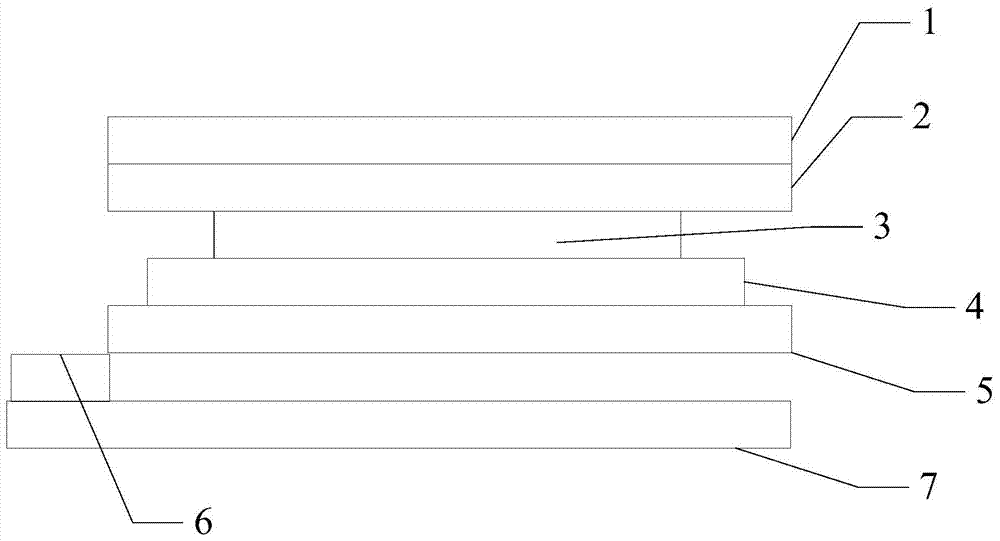

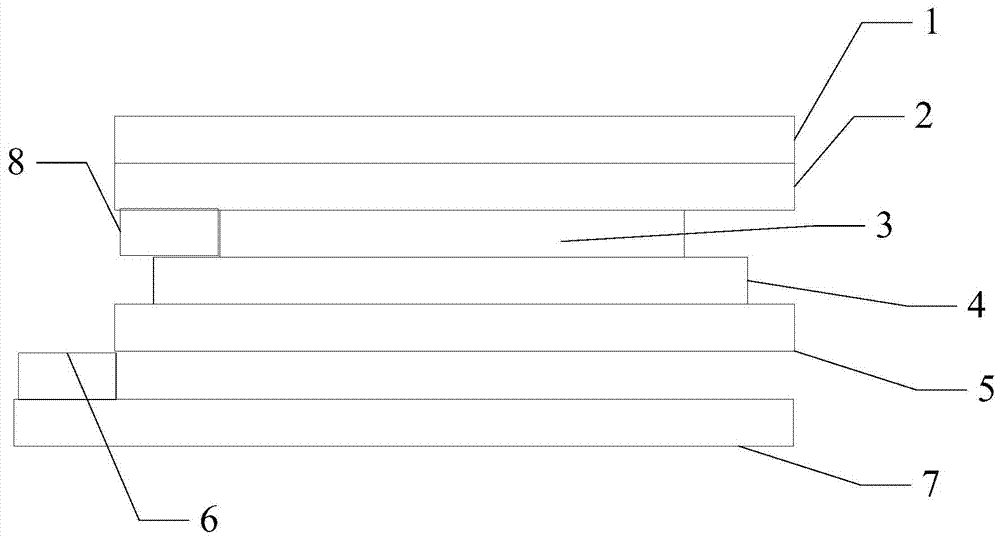

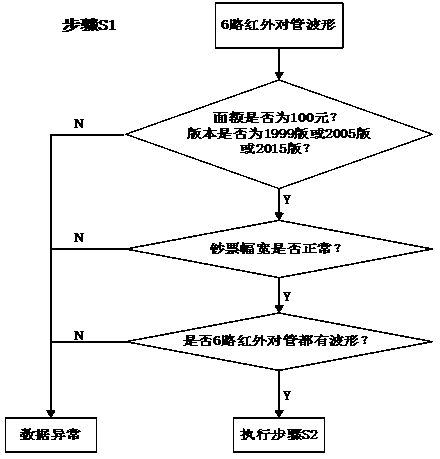

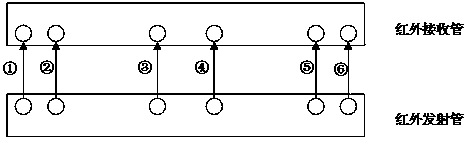

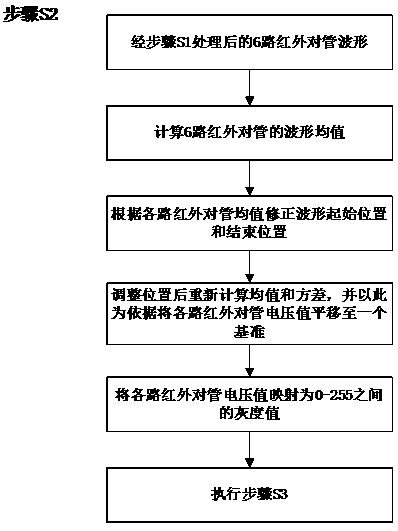

Depth learning based and infrared geminate transistor employed authenticity identification method of currency detector

ActiveCN108335402AProcessing speedGood anti-counterfeiting functionPaper-money testing devicesCharacter and pattern recognitionLearning basedComputer science

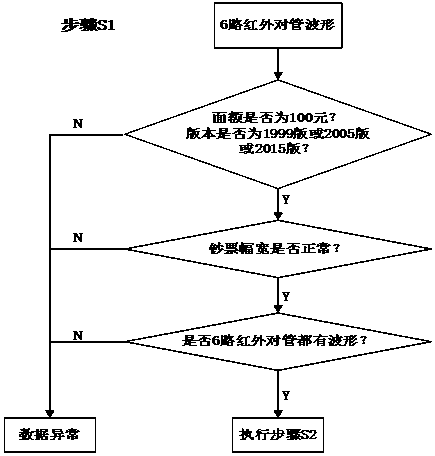

The invention discloses a depth learning based and infrared geminate transistor employed authenticity identification method of a currency detector and belongs to a field of infrared authenticity identification. The method includes performing signal correctness verification according to multiple channels of infrared geminate transistor waveforms; performing pretreatment on the multiple channels ofthe infrared geminate transistor waveforms; generating a two-dimensional array, converting to an image and processing; performing currency authenticity identification by utilizing the infrared geminate transistor waveforms and adopting CNN training and a detection process in depth learning. The method provided by the invention can realize a good authenticity identification function at a comparatively high processing speed with high accuracy.

Owner:武汉卓目科技有限公司

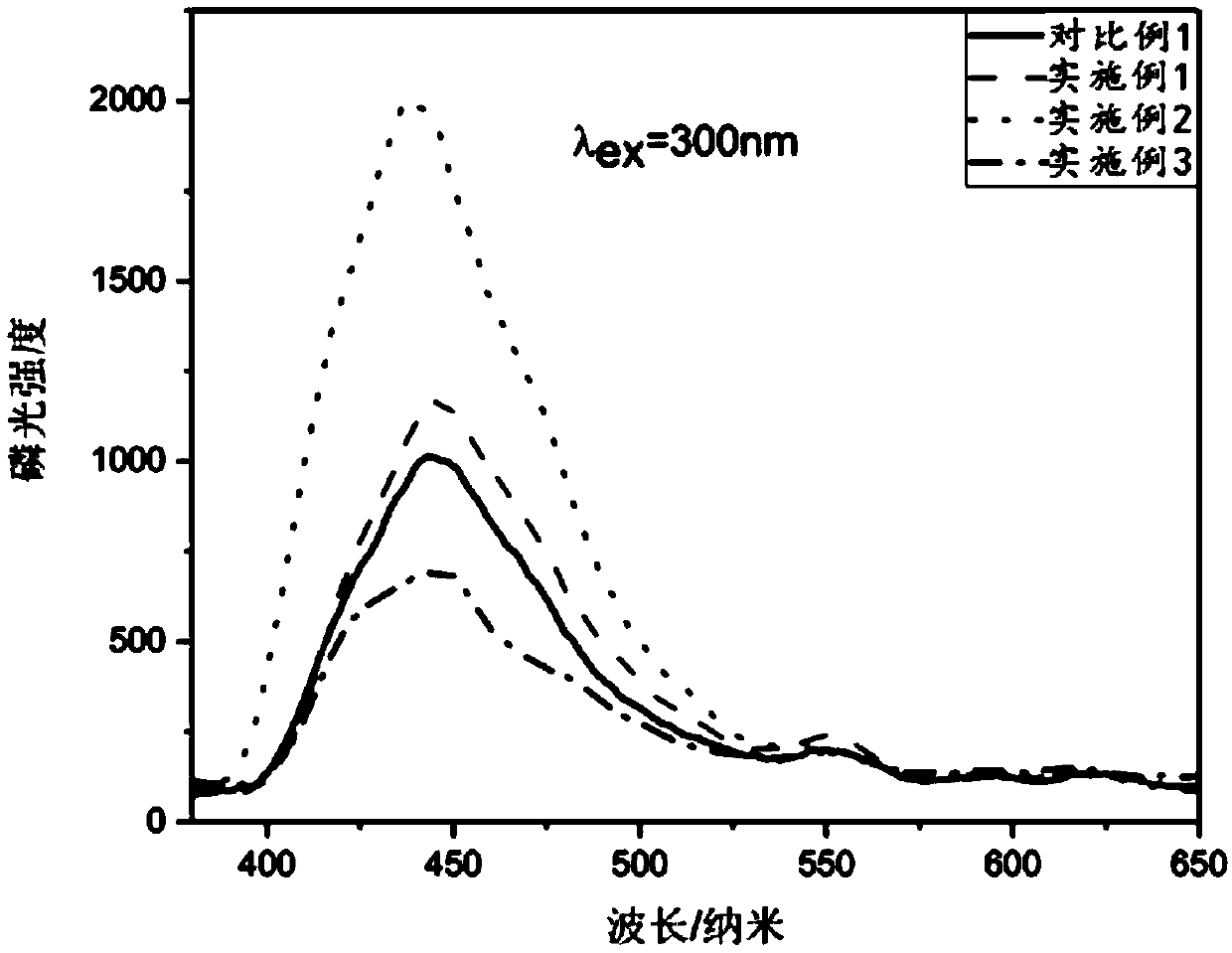

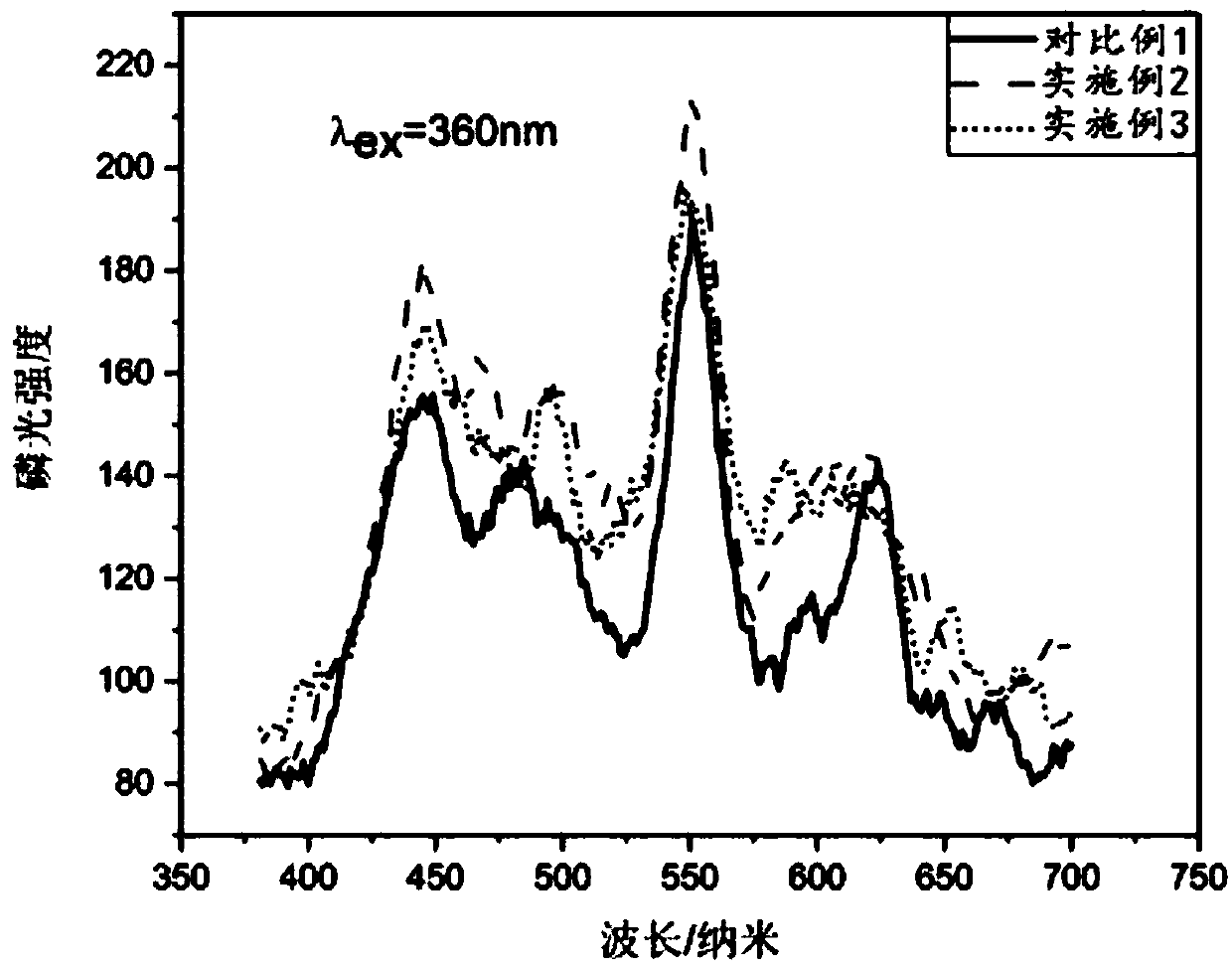

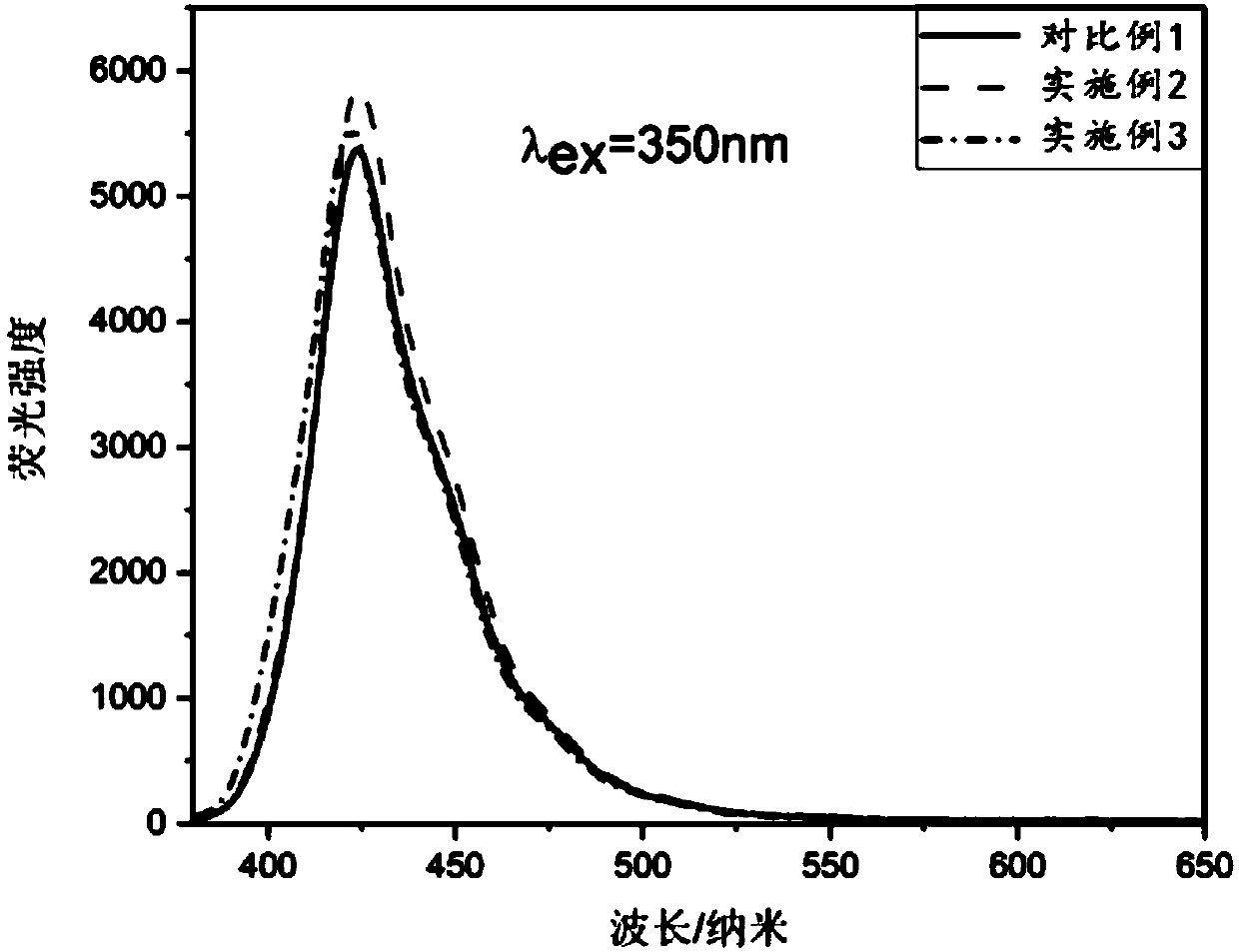

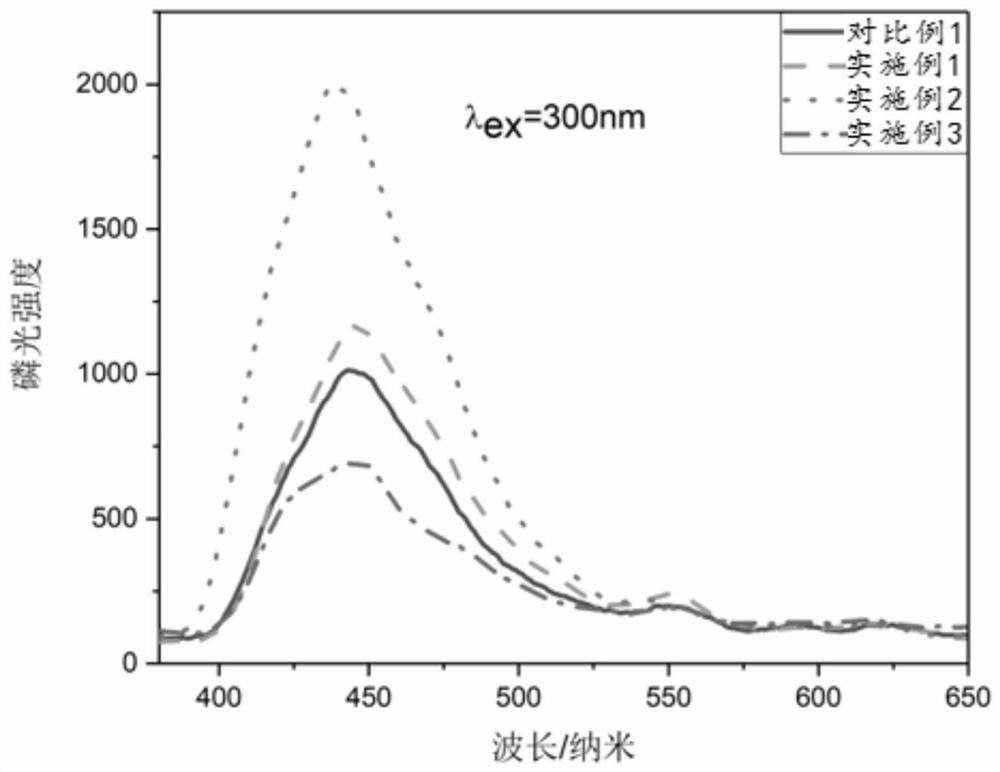

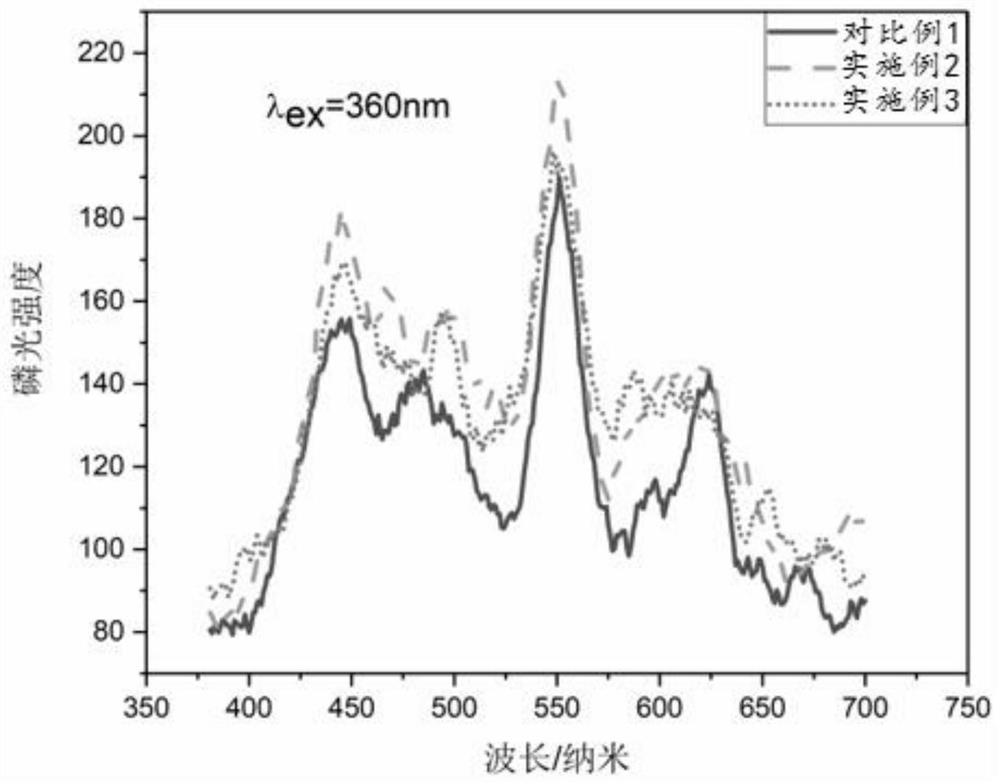

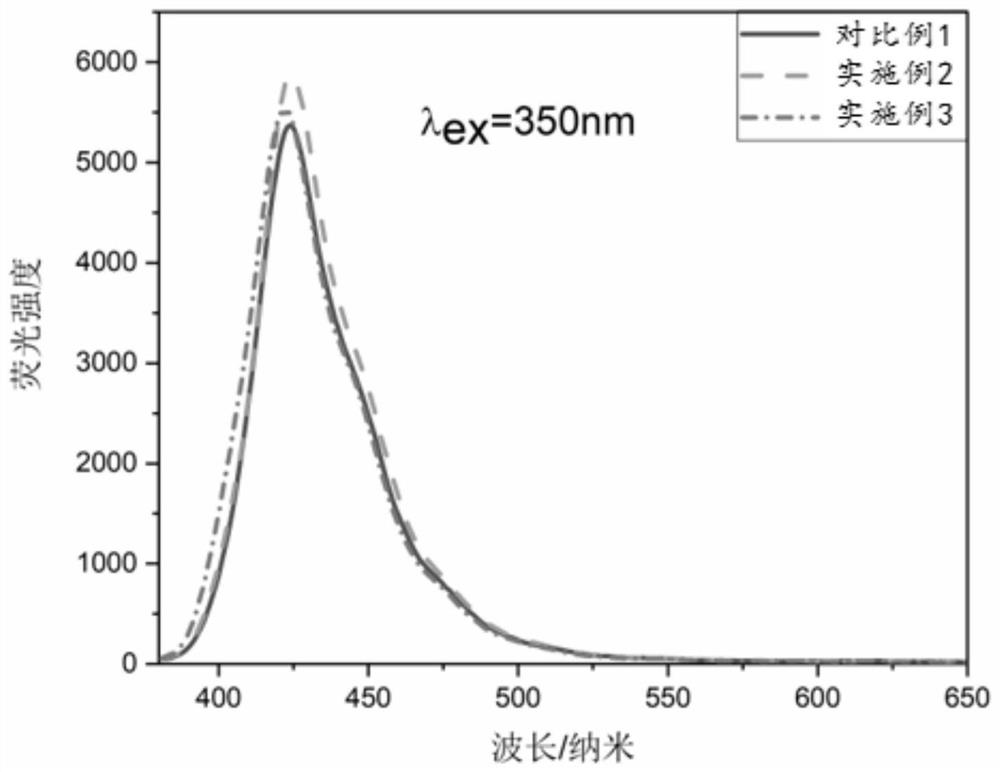

Organic long-afterglow material as well as preparation method and application thereof

ActiveCN110079301AImprove flexibilityHigh transparencyLuminescent compositionsCarbazolePolyvinyl alcohol

The invention discloses an organic long-afterglow material as well as a preparation method and an application thereof. The organic long-afterglow material comprises a host molecule and a guest molecule, wherein the host molecule is carbazole, and the guest molecule is diphenylphosphinic anhydride. The host molecule and the guest molecule are mixed in a certain mass ratio and doped in a polyvinyl alcohol solution, the mixture is applied to a base material and dried to form a film, and an organic room-temperature phosphorescent material can be obtained. The preparation method is simple and easyto control and ingredients are simple. The material has good flexibility and transparency, the phosphorescence intensity of carbazole is notably improved and the phosphorescence lasting time of carbazole is remarkably prolonged through doping of the guest molecule, and the afterglow lasting time can reach 22 s. Fluorescence emission and phosphorescence emission under the room temperature conditionare realized simultaneously, and the organic long-afterglow material has high stealthiness and is convenient to use and easy to recognize, thereby realizing the high-grade anti-counterfeiting function. The organic long-afterglow material has good application prospects in the fields of organic optoelectronic materials, anti-counterfeiting, encryption and the like.

Owner:CHONGQING UNIV OF TECH

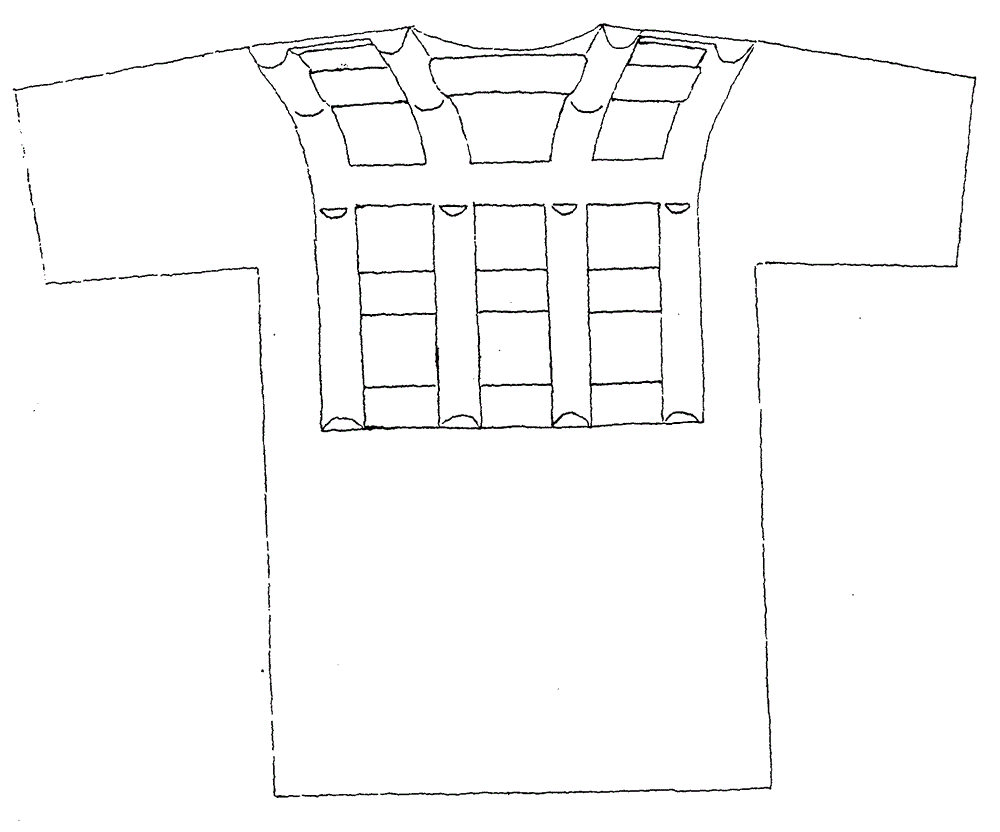

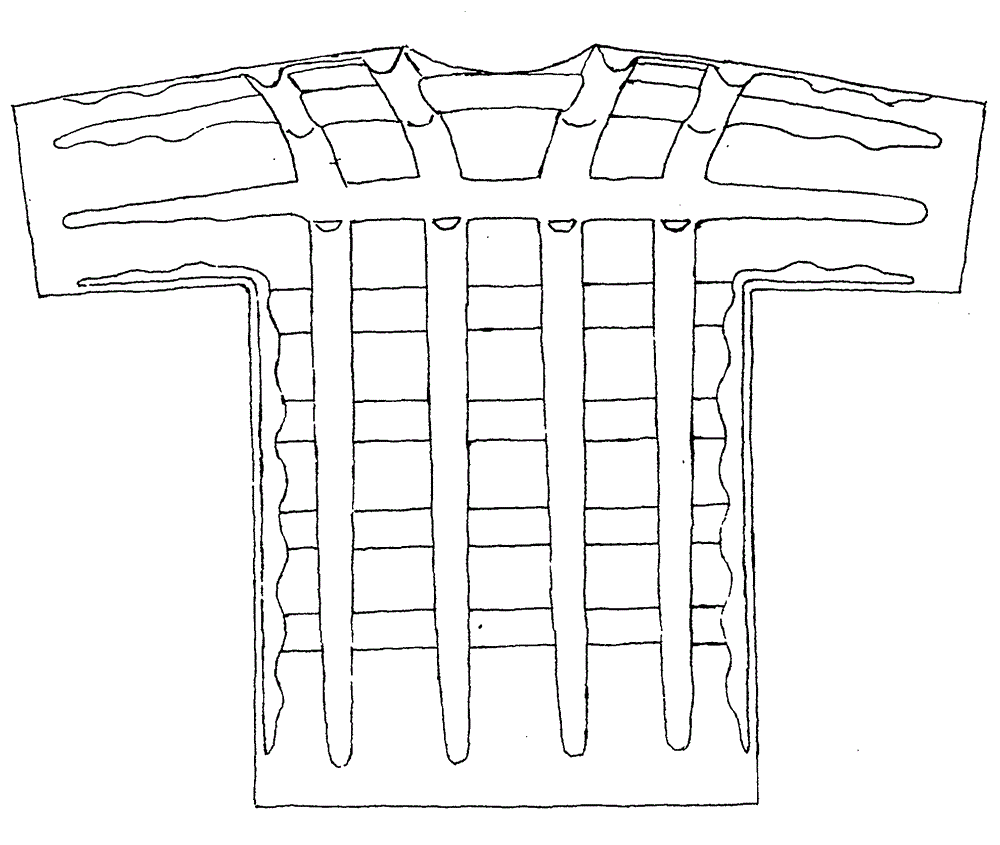

Cooling sun-protective clothes

InactiveCN104000316AGood anti-counterfeiting functionFit close to the bodyProtective garmentSpecial outerwear garmentsHollow coreEngineering

The invention relates to cooling sun-protective clothes for people to wear, which is specially used for cooling and protecting against the sun and belongs to clothing industries including rubber manufacturing industry, rubber processing industry, clothes design and clothes manufacturing industry. The clothes belong to a fabric as well as a rubber product. The first generation and second generation sun-protective skirts have multiple advantages, but are rubber products which are not suitable for people to wear. Moreover, the skirts are too heavy without special counterfeit means. The shape of the cooling sun-protective clothes is the same as those of the first generation and second generation sun-protective skirts. The cooling sun-protective clothes differ from the first generation and second generation sun-protective skirts in that the inner side of the entire clothes is coated with a layer of textile which is suitable for being directly contacted with human body and is hydrophilic, moisture-permeable and air-permeable. Clothes ribs on the inner side are hollow, and an anti-counterfeit pattern is directly carved on the surface of the outerwear by using laser. By adopting the cooling sun-protective clothes, the defects that the sun-protective skirt is not suitable for people to wear and has poor anti-counterfeiting function and great weight are overcome.

Owner:赵洪波

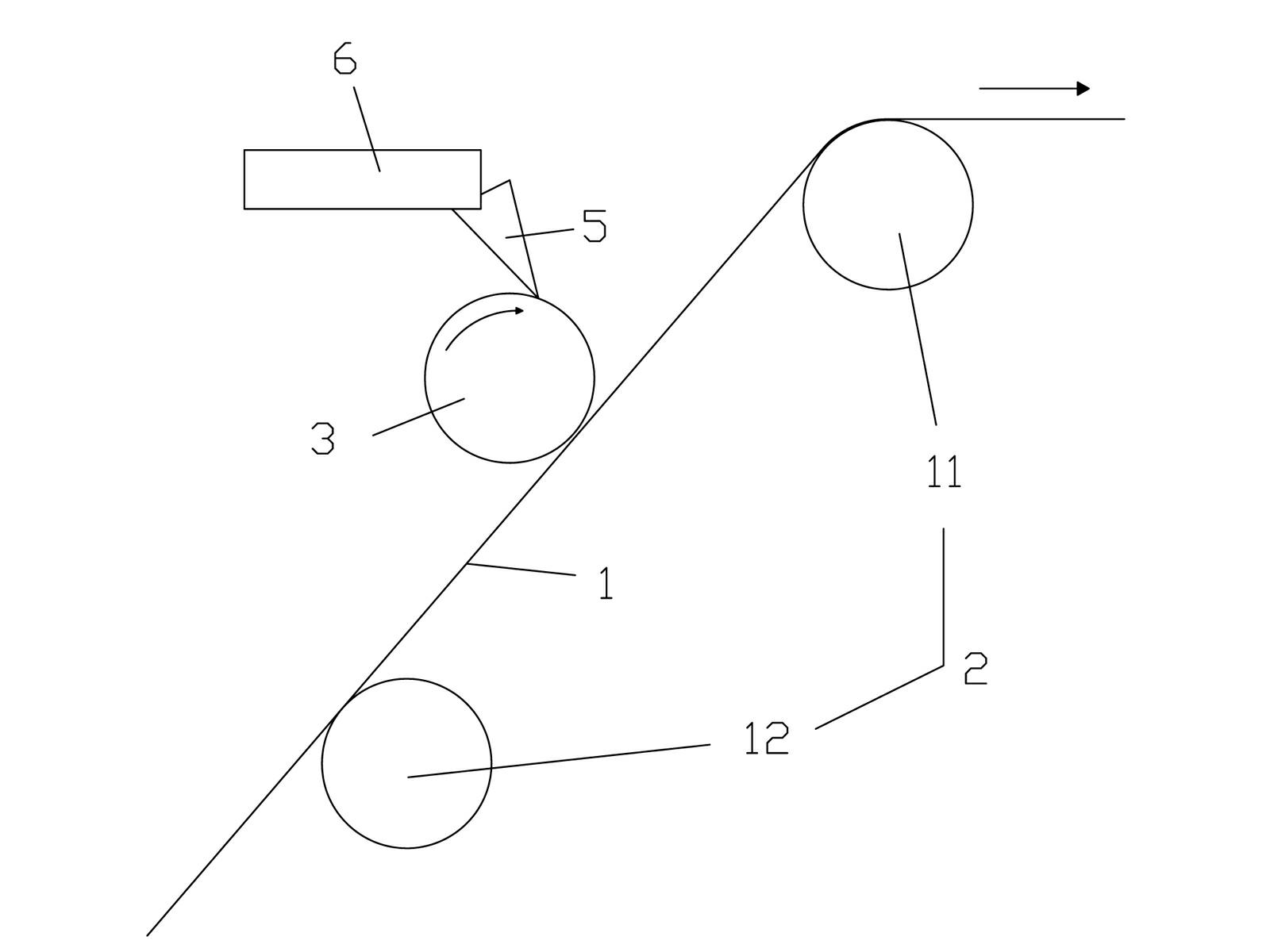

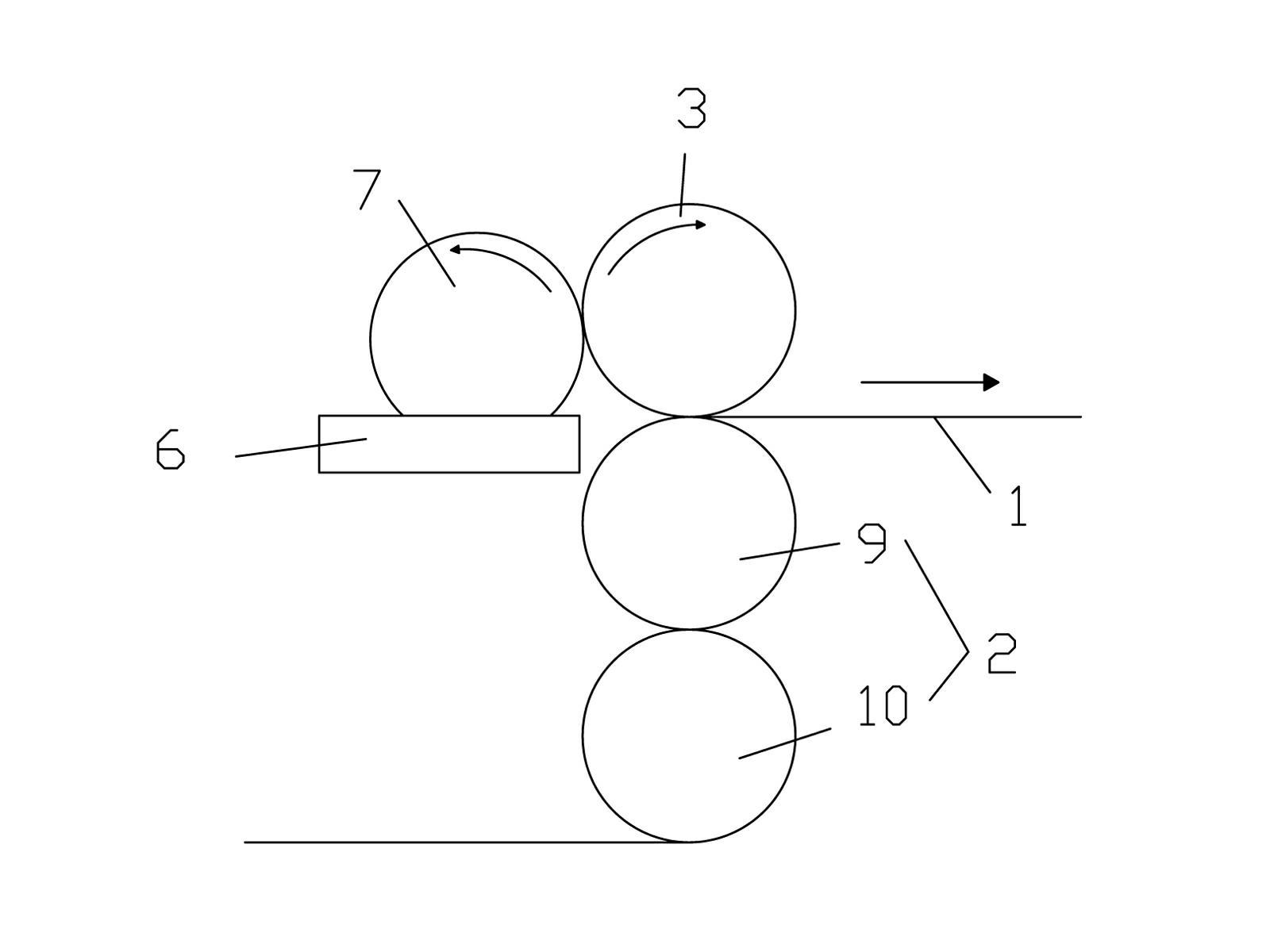

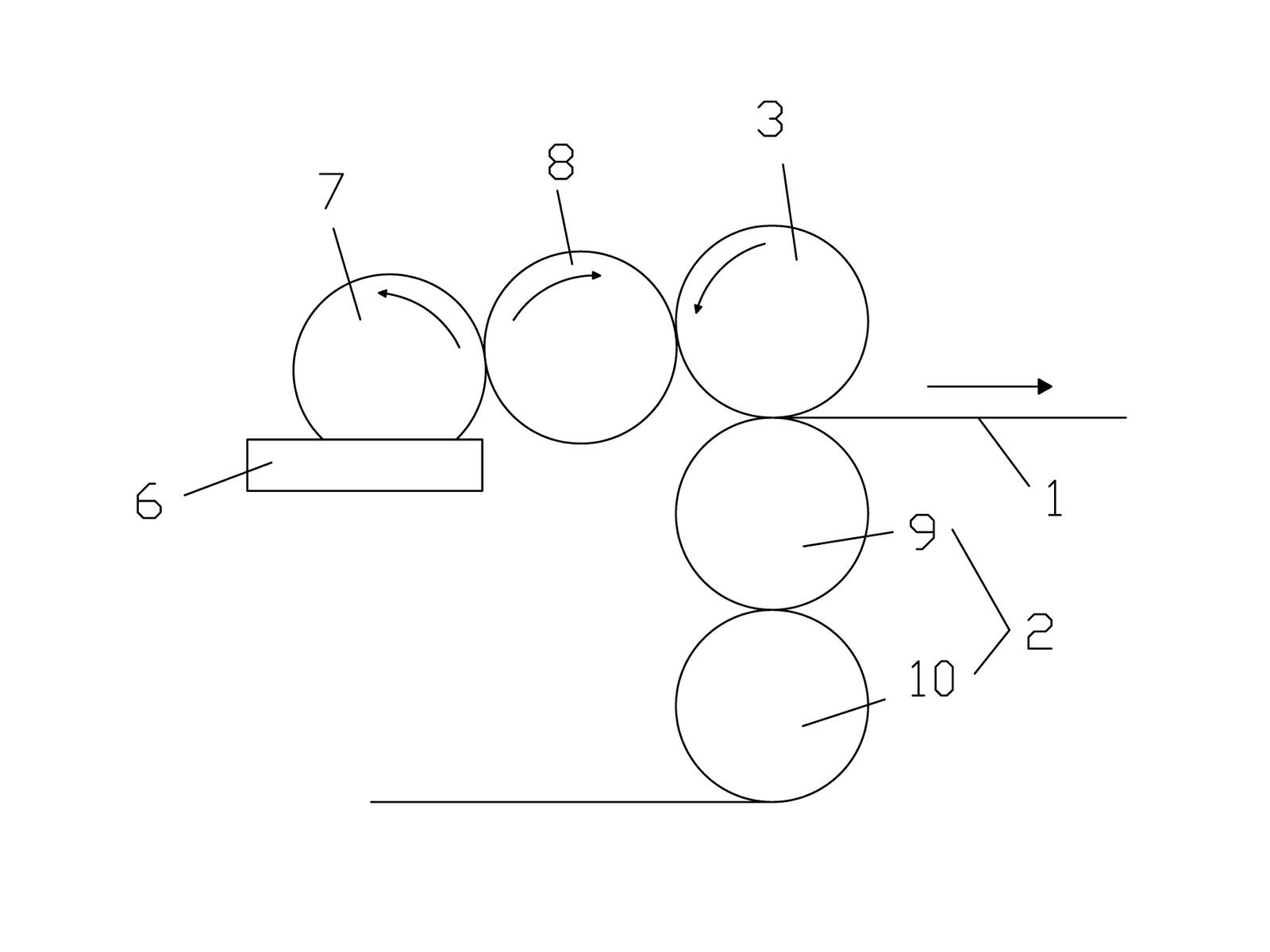

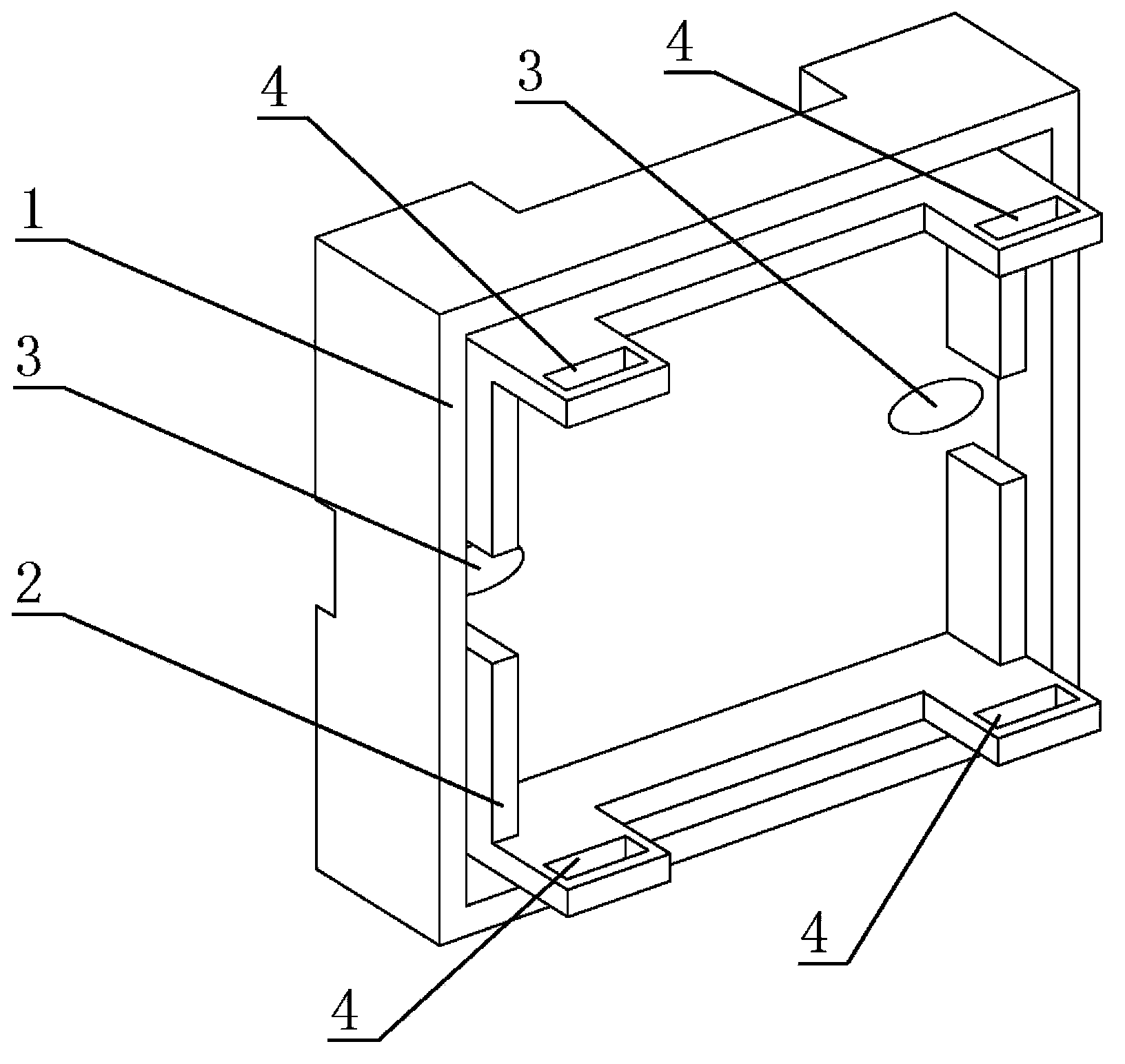

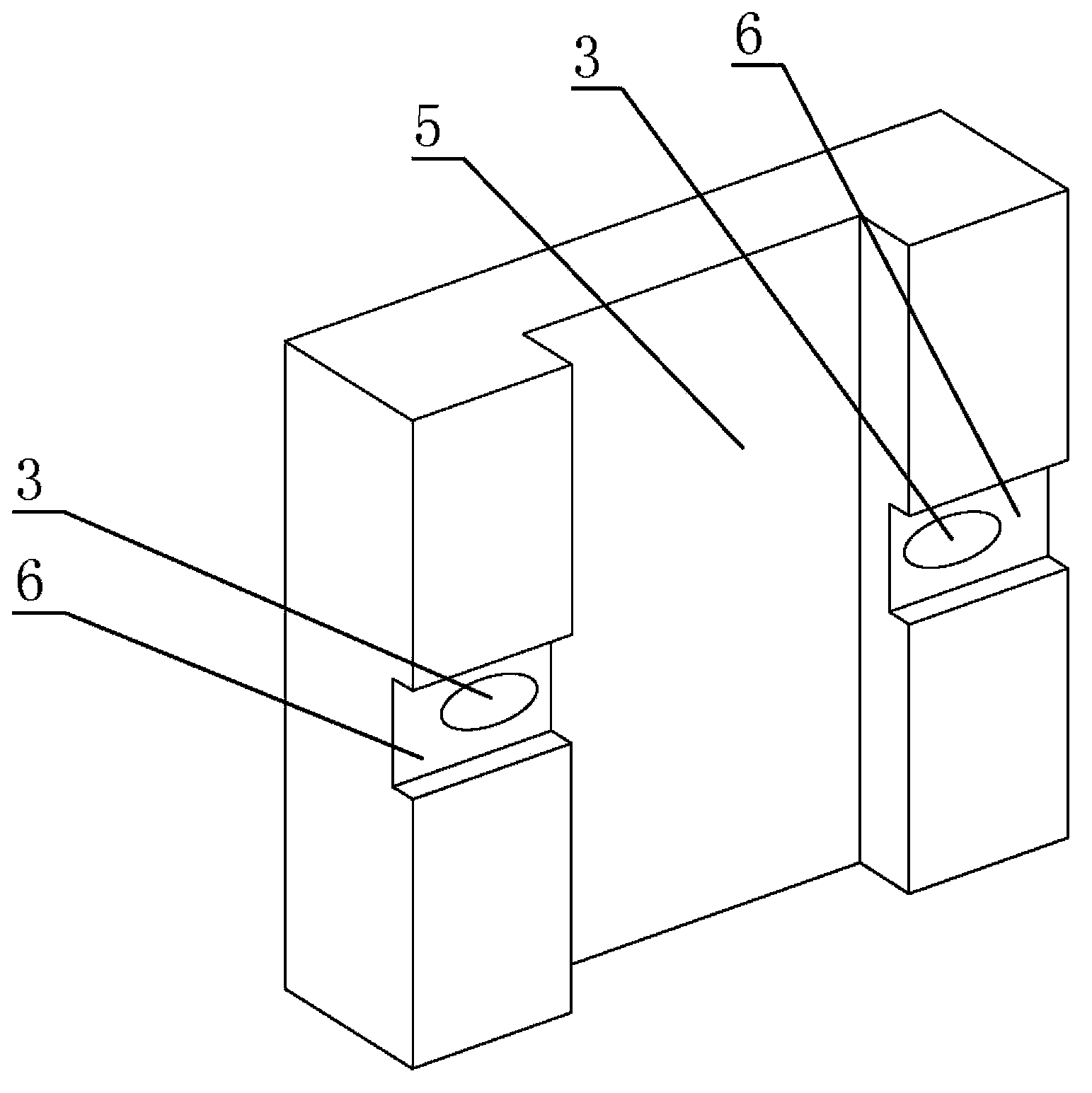

Rolling printing device for metal coil and rolling printing method for metal coil

InactiveCN102189746AImprove visual functionGood anti-counterfeiting functionRotary intaglio printing pressOther printing apparatusMetalElectrical and Electronics engineering

The invention discloses a rolling printing device for a metal coil and a rolling printing method for the metal coil, wherein the rolling printing device comprises a support part, a printing roller and a printing material charging part; when in rolling printing, the steps are as follows: selecting a required printing pattern, engraving the printing pattern on the surface of the printing roller, then arranging a coil baseplate on the support part, enabling the surface of the printing roller to be jointed and butted on the coil baseplate, using the printing material charging part to charge printing material onto the printing roller, moving the coil baseplate on the support part, enabling the printing roller to rotate, and using the printing roller to print the printing pattern on the coil baseplate. By adopting the rolling printing device for the metal coil, the whole rolling printing process can be continuously performed, the processing efficiency is very high, and a processed coil product has better appearance vision and anti-counterfeiting function; and the rolling printing method for the metal coil is convenient to process and simple to control, and can greatly improve the shortcomings of the traditional single-sheet plane printing and fill in a technical blank in the aspect of continuous whole coil printing.

Owner:ZHUHAI SANYUAN ALUMINUM

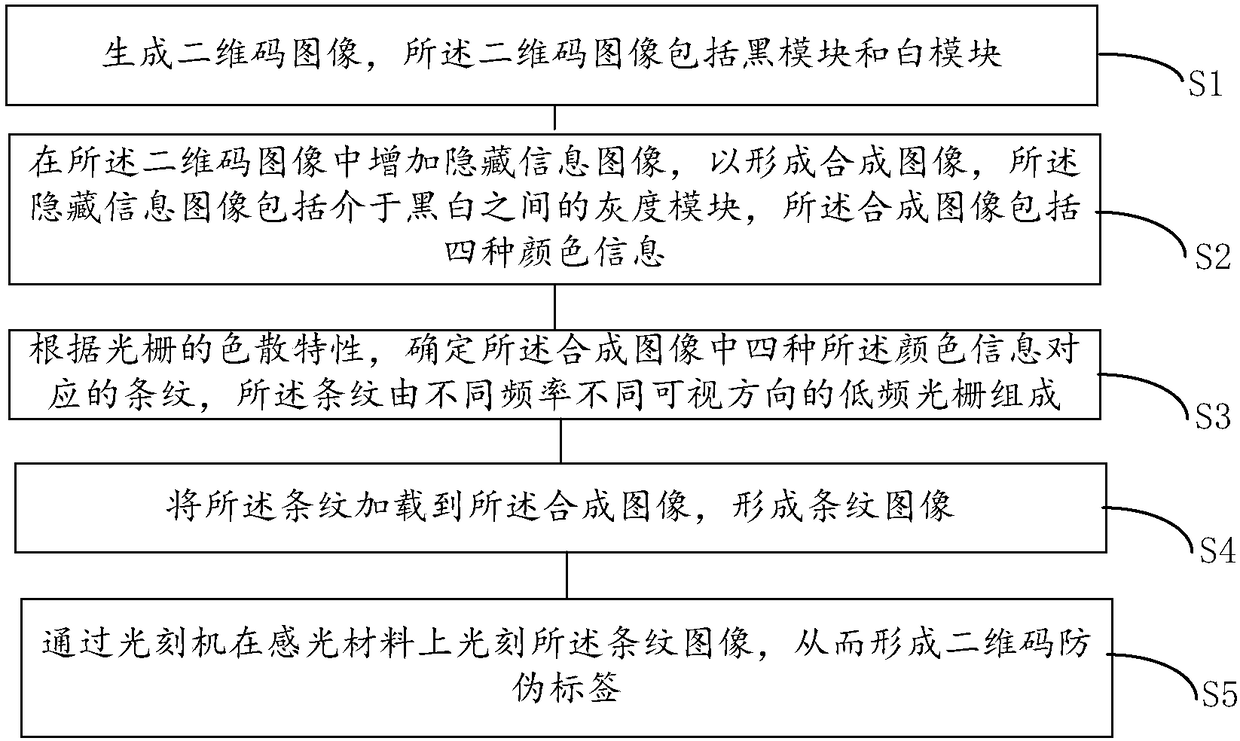

Two-dimensional code anti-counterfeit label and manufacturing method thereof

PendingCN108090542AGood anti-counterfeiting functionLow costPhotomechanical exposure apparatusImage data processing detailsGray levelComputer hardware

The invention discloses a two-dimensional code anti-counterfeit label. The two-dimensional code anti-counterfeit label comprises four stripes which correspond to four kinds of color information respectively, and the stripes are constituted by low-frequency optical gratings with different frequencies and different visible directions; the color information comprises black, white, a first gray leveland a second gray level; the black corresponds to a black module area of a two-dimensional code image in the two-dimensional code anti-counterfeit label, the white corresponds to a white module area of the two-dimensional code image, the first gray level corresponds to a coincident area of a hidden information image in the two-dimensional code anti-counterfeit label and the black module area, andthe second gray level corresponds to a coincident area of the hidden information image and the white module. By means of the two-dimensional code anti-counterfeit label, an excellent anti-counterfeitfunction of the two-dimensional code label can be achieved, information can be simply hidden and obtained without the assistance of any auxiliary equipment, and the two-dimensional code anti-counterfeit label is low in cost and easy to use.

Owner:SHENZHEN SHENDA AURORA TECH

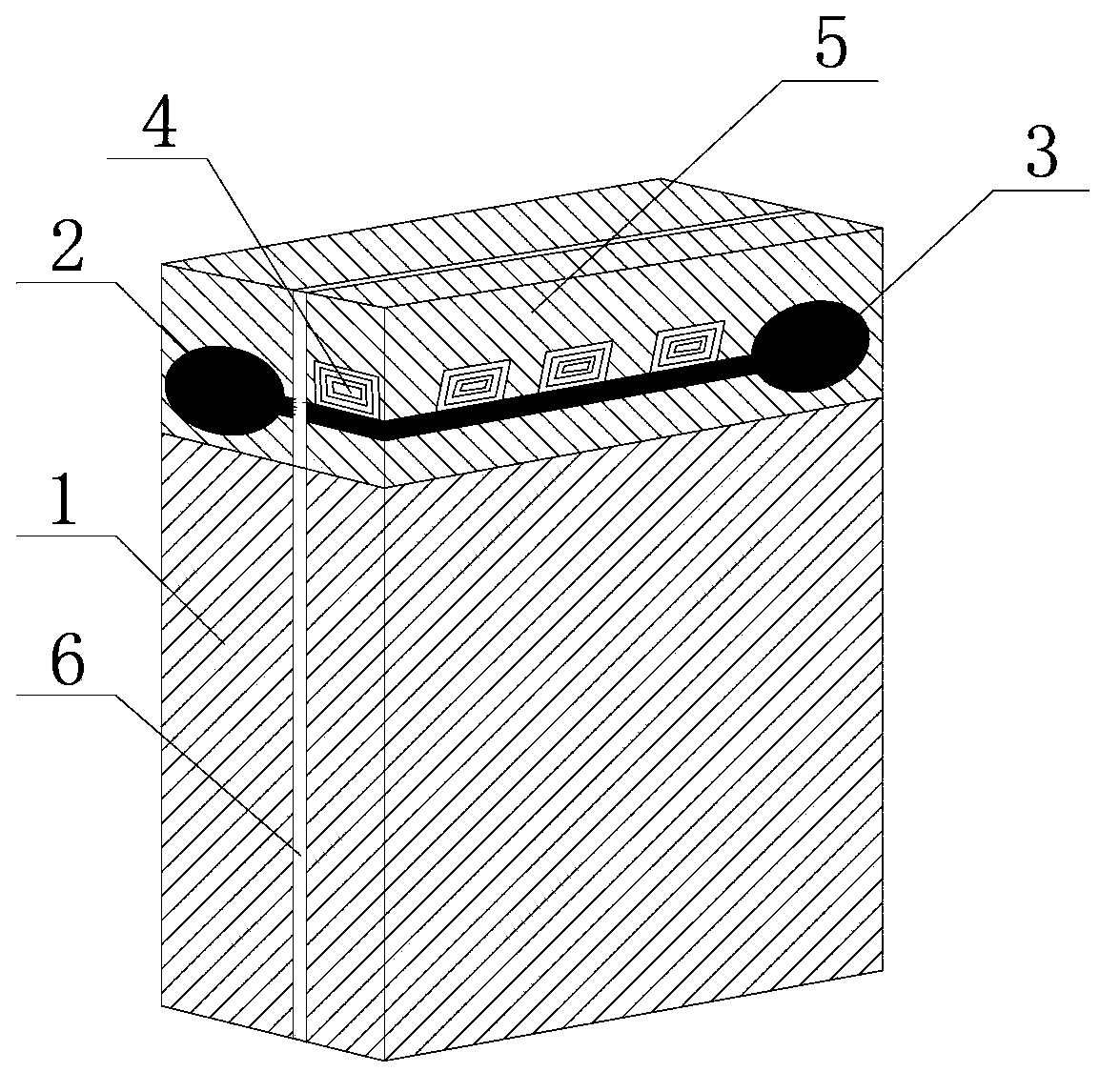

Tobacco FRID label with anti-counterfeiting function

InactiveCN103413167ABig designWon't get angryRecord carriers used with machinesBiotechnologyMicrobiology

The invention discloses a tobacco FRID label with an anti-counterfeiting function. The tobacco FRID label comprises a tobacco box, tinfoil, a golden silk thread, a chipless RFID label and a tobacco box peripheral packing box. The tinfoil is arranged on the inner wall of the tobacco box, the golden silk thread is arranged on an opening of the tobacco box, the tobacco box peripheral packing box is arranged at one end, or at two ends or on two adjacent surfaces of the tobacco box, and the chipless RFID label is printed on the tobacco box. According to the tobacco FRID label with the anti-counterfeiting function, the tobacco box peripheral packing box and the chipless RFID label are additionally arranged on the tobacco box, the label can be visited from any angle, the structure is simple, the label can be designed to be very wide, a good omnidirectional radiation characteristic and the anti-counterfeiting function are achieved, the tinfoil is completed, the moistureproof function of the tobacco box can not be lost due to the additionally-arranged chipless RFID label, and therefore tobaccos can not lose flavour.

Owner:章伟

Fluorescent anti-counterfeiting printing ink

The invention provides fluorescent anti-counterfeiting printing ink. The fluorescent anti-counterfeiting printing ink comprises the following components: 5-10 parts of nitro-cotton, 5-10 parts of epoxy resin, 5-10 parts of a solvent type fluorescent dye, 1-2 parts of fluorescent powder, 70-80 parts of an organic solvent, 0.1-0.5 part of polyoxyethylene octyl phenol ether-10, and 0.1-0.7 part of N-methyl pyrrolidone; and the solvent type fluorescent dye is chosen from one or more of fluorescent orange red, fluorescent red and fluorescent peach. The provided fluorescent anti-counterfeiting printing ink is orange-yellow under the synergic action of the components at the specific contents, and shows orange-yellow fluorescence under the irradiation of an ultraviolet lamp; the ink is orange redand shows orange red fluorescence under the irradiation of the ultraviolet lamp; and the invisible fluorescent ink and the apparent style ink are organically combined, and therefore, the anti-counterfeiting function of the fluorescent anti-counterfeiting printing ink is better.

Owner:北京靛铕精细化工厂 +1

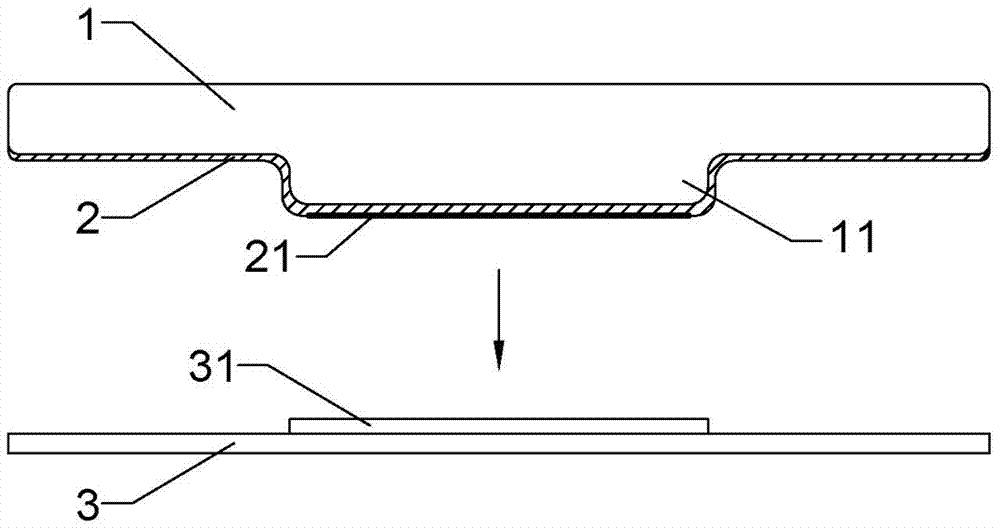

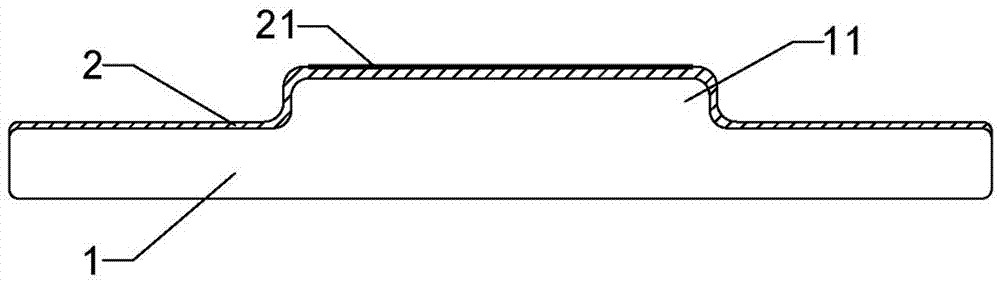

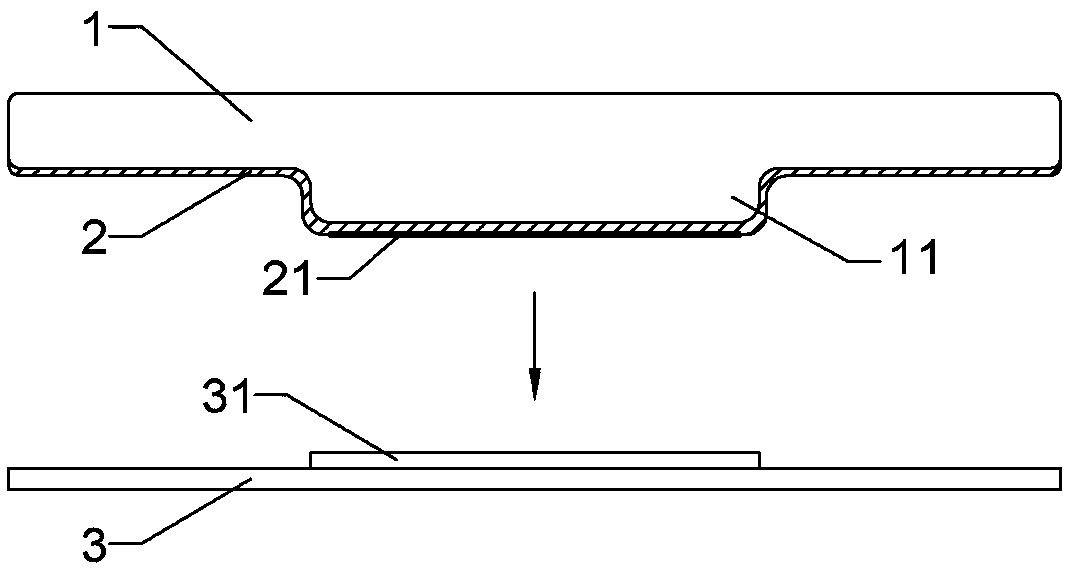

Non-alumite gold stamping product and preparation process thereof

ActiveCN107042723AHigh reuse rateAvoid wastingNon-macromolecular adhesive additivesDecorative surface effectsGraphicsHot stamping

The invention relates to the technical field of printing gold stamping, in particular to a non-alumite gold stamping product and a preparation process thereof. The preparation process of the non-alumite gold stamping product comprises the following steps that A, a combination plate is prepared, specifically, a gold stamping plate and a laser nickel plate with graphics and text information being carved are subjected to alignment and laminating through high temperature resistant glue to prepare the combination plate; B, paper is coated, specifically, the position, needing gold stamping, of the paper is coated with thermoplastic light oil or high-reflectivity coating to prepare a coating layer; and C, coating and gold stamping are conducted, specifically, the combination plate prepared in the step A is subjected to lock up and put on a machine, the coating layer prepared in the step B is pressed and subjected to gold stamping, and the non-alumite gold stamping product is prepared. The graphics and text information of the laser nickel plate can be printed on the paper in a hot stamping mode under the condition of no alumite medium, various laser effects can be shown on the paper through one procedure, the production cost is low, durability is good, the customization period is short, safety and environmental friendliness are achieved, and the multi-batch and small-amount production requirements are met.

Owner:HUCAIS PRINTING

Soft plastic packaging bag with anti-counterfeiting identification and manufacturing method thereof

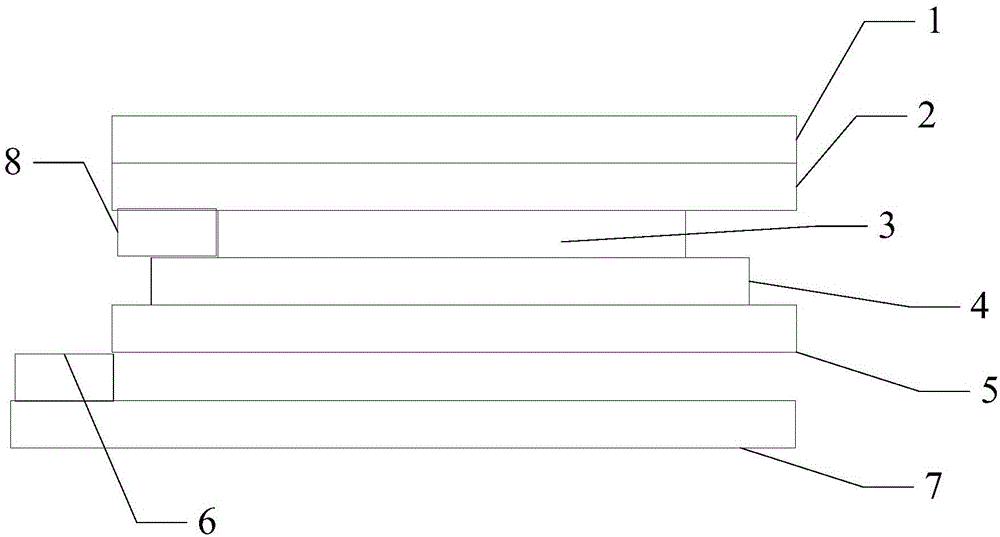

The invention discloses a soft plastic packaging bag with an anti-counterfeiting identification. The soft plastic packaging bag comprises a plastic surface layer, an identification attachment layer, a two-dimension-code-variable identification layer, a supporting layer, a plastic bottom layer, a bar-code-variable identification layer and a protective layer. The identification attachment layer is arranged on the lower surface of the plastic surface layer in a coated mode. The two-dimension-code-variable identification layer is printed to the lower surface of the identification attachment layer in a sprayed mode. The supporting layer is sprayed on the lower surface of the two-dimension-code-variable identification layer to support the two-dimension-code-variable identification layer. The plastic bottom layer is located on the lower surface of the supporting layer and attached to the plastic surface layer. The bar-code-variable identification layer is attached to the lower surface of the plastic bottom layer and located at the lower end of the identification attachment layer. The batch number of a product is printed below the number of the bar-code-variable identification layer in a sprayed mode. The protective layer is located on the lower surface of the bar-code-variable identification layer and attached to the plastic surface layer. The invention further provides a manufacturing method of the soft plastic packaging bag. The anti-counterfeiting identification arranged on the soft plastic packaging bag is resistant to damage and obliterating and is unique relative to the product in the soft plastic packaging bag, and meanwhile the good anti-counterfeiting function is achieved.

Owner:GUANGXI RONGXIAN FENGCAI PRINTING IND

Anti-counterfeiting two-color cap and production method thereof

InactiveCN103419322AGuarantee sustainable developmentPromote healthy developmentCapsClosure capsInjection mouldingMechanical engineering

Owner:广东鼎湖山泉有限公司

Water-based rare-earth up-conversion fluorescent ink as well as preparation method thereof and anti-counterfeit application

ActiveCN108250843AGood compatibilityPromote environmental protectionPattern printingInksDispersed mediaFluorescence

The invention relates to the technical field of anti-counterfeit printing, and discloses a preparation method of water-based rare-earth up-conversion fluorescent ink. The method takes water-based polyurethane (WPU) prepolymer as an organic ligand; types of doped rare-earth ions are changed, and a hydro-thermal synthesis method is adopted for obtaining a water-based rare-earth fluoride up-conversion light-emitting material with high light-emitting strength; the water-based rare-earth fluoride up-conversion light-emitting material is added into an ink system, water-based polyurethane is taken asa connecting material, water is taken as a dispersing medium, and the water-based rare-earth up-conversion ink is prepared through processes such as pre-dispersing, high-speed stirring and homogenizing; and a needed pattern is obtained on printing stock through a sealing or concave-sealing mode. The water-based rare-earth up-conversion fluorescent ink prepared by the method disclosed by the invention has the advantages of good environment friendliness, strong anti-counterfeit capability grade, high light-emitting strength, good printability, capability of showing various printings tock materials, simple operation, short period, and the like, and can be printed on bills, negotiable securities, trade marks or packages on a large scale, so that a product has a relatively high anti-counterfeit function.

Owner:HUNAN UNIV OF TECH

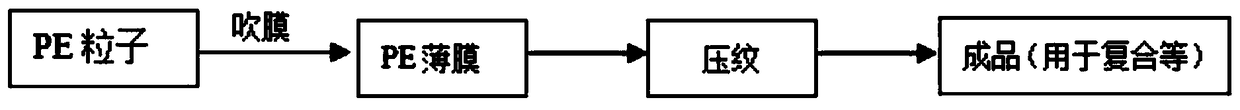

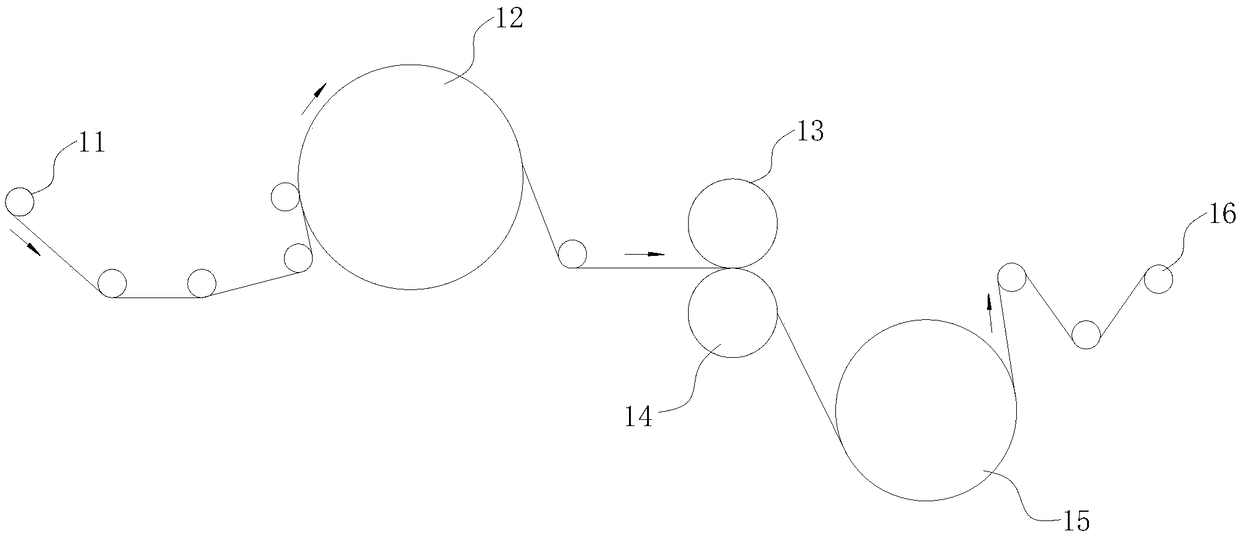

Polyethylene embossed packaging film and production process thereof

InactiveCN109016750AExcellent stiffness performanceGood haze effectFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention relates to a polyethylene embossed packaging film and a production process thereof. The polyethylene embossed packaging film is obtained by heating and softening of a polyethylene blownfilm and embossing treatment. The polyethylene blown film comprises a corona layer, an intermediate layer and a heat seal layer. The corona layer comprises 48-52wt.% of low density polyethylene (LDPE)and 48-52wt.% of linear low density polyethylene (LLDPE), the intermediate layer includes linear low density polyethylene (LLDPE), and the heat seal layer comprises 32-36wt.% low density polyethylene(LDPE) and 64-68wt.% linear low density polyethylene (LLDPE). Compared with cast embossed films, the polyethylene embossed packaging film provided by the invention can show good stiffness effect andhaze effect, and has high heat seal strength, impact resistant strength, other excellent physical and mechanical properties, etc.

Owner:HUANGSHAN NOVEL

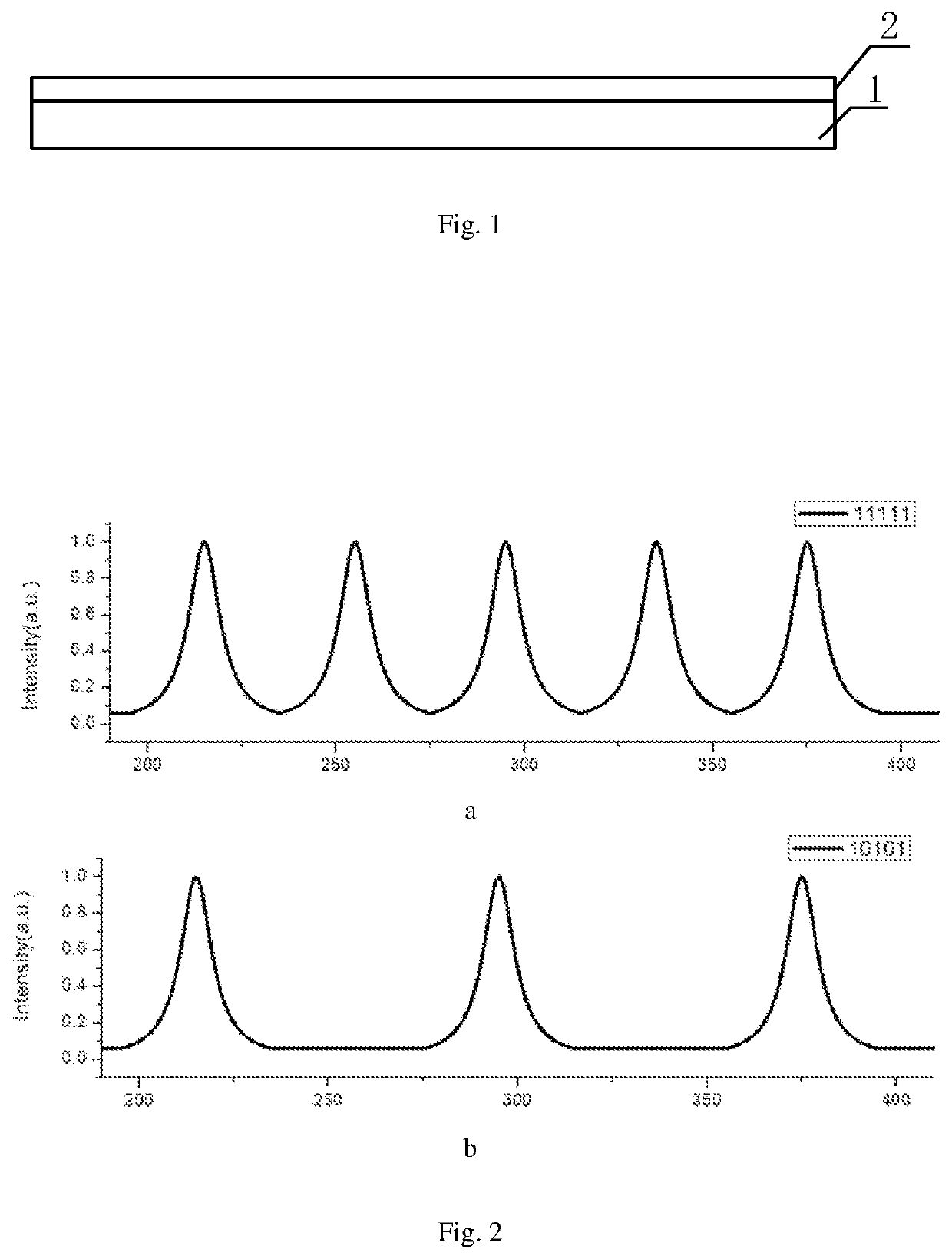

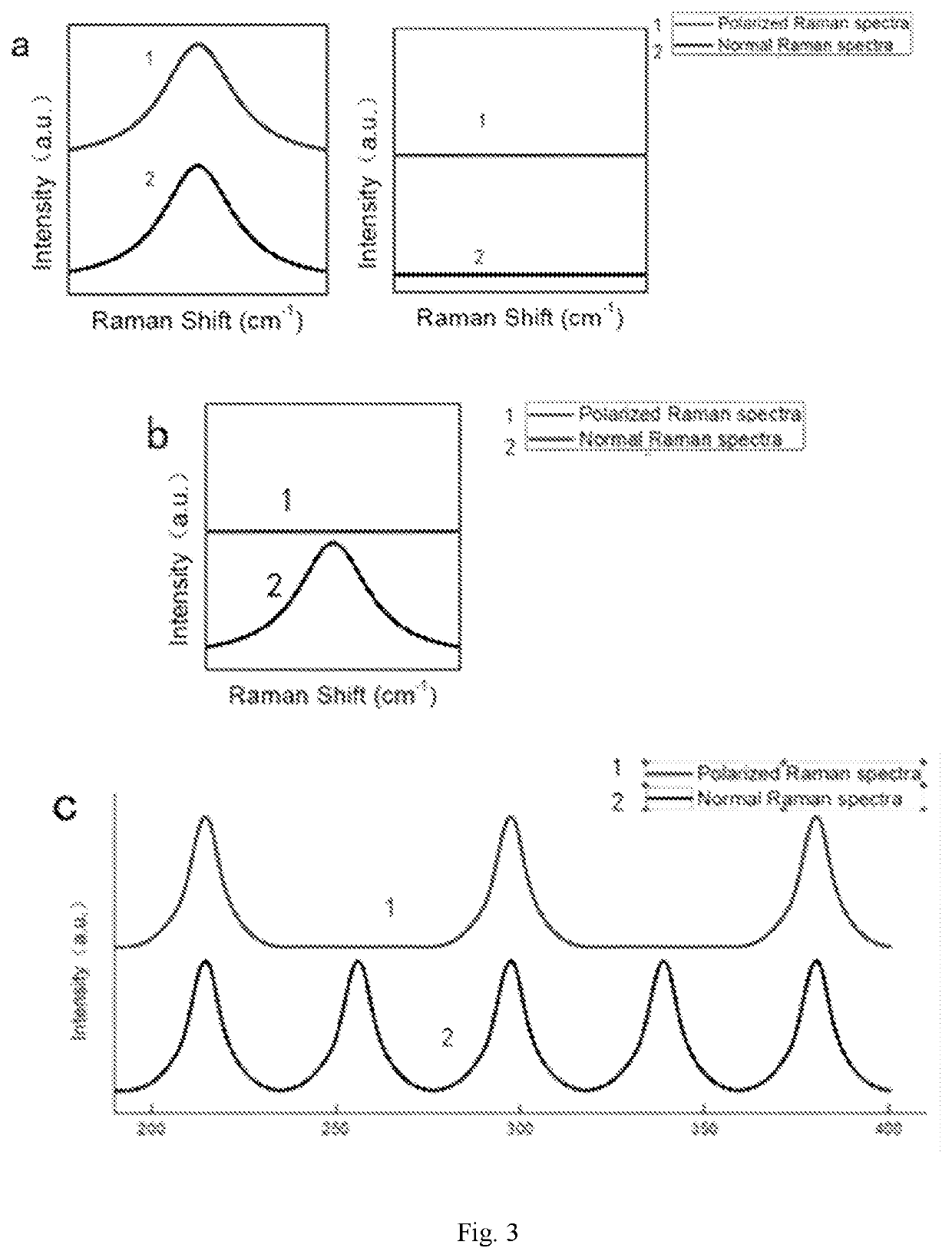

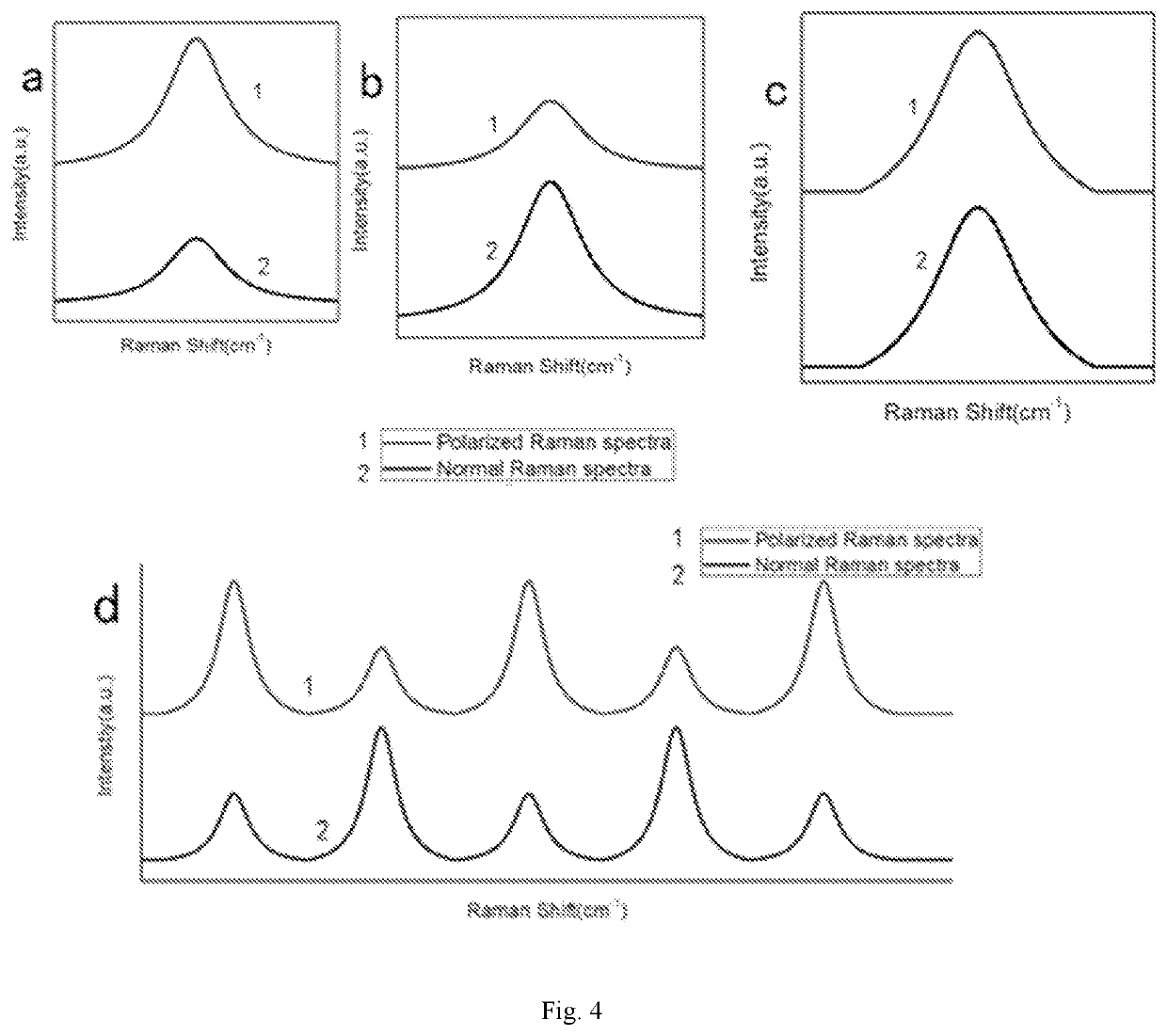

Polarized Raman spectrum coding-based nano barcode smart label

The present disclosure provides a polarized Raman spectrum-based nano barcode smart label, including: a substrate and a nanoparticle coding layer that is provided on the substrate and can be coded by polarized Raman spectrum coding, wherein the nanoparticle coding layer that can be coded by polarized Raman spectrum coding is a mixed layer including a plurality of nanomaterials having different Raman characteristic peaks; under different polarization detection states, the Raman characteristic peaks can exhibit coding characteristics that are totally different from those under a non-polarization detection state and are distinguished from those of a conventional Raman peak position, so as to achieve spectral characteristics for multiple coding. During use of the smart label of the present disclosure, a corresponding nano barcode detection system is used to detect a brand label provided with the encoded nanoparticles to obtain coding information of the brand label.

Owner:NANJING UNIV

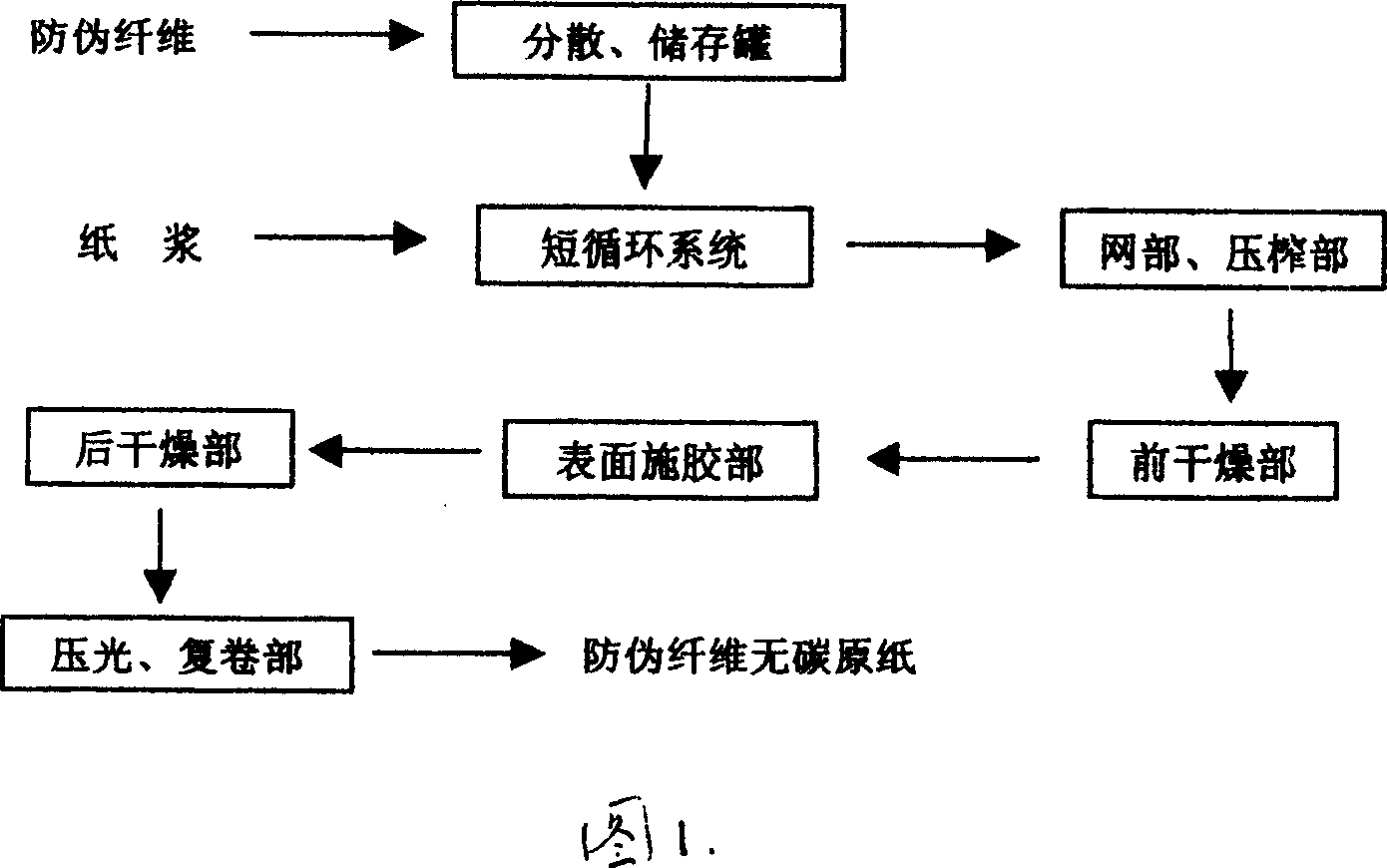

Anticounterfeit fiber carbor-free copy paper and its production method

ActiveCN1306116CGood anti-counterfeiting functionImprove yieldSpecial paperPaper coatingFiberPulp and paper industry

This invention relates to an anti-false fiber noncarbon paper and its production method aiming at overcoming the shortcoming of not anti-false of the current bills made of carbon copy paper which is made by adding a certain quantites of anti-false fiber original paper to produce primary anti-false then to be specially coated to produce the noncarbon paper with anti-false function.

Owner:GUANGDONG GUANHAO HIGH TECH

Method for manufacturing chemical anti-counterfeiting paper

InactiveCN102168391AIncrease the difficultyHigh riskNon-macromolecular organic additionIsobenzofuranPhenolphthalein

The invention provides a method for manufacturing chemical anti-counterfeiting paper, relating to the technical field of counterfeiting prevention of special paper. The method comprises the following steps: mixing 3,3-dual(4-hydroxybenzene group)-1(3H)-isobenzofuranone with water in a certain proportion, and then finely grinding the mixture by virtue of a ball mill; then, in a glue solution added into a filled or subjected to top sizing during the paper manufacturing process, manufacturing body paper with pulp according to the common method so that the body paper contains phenolphthalein; or in a painting added during the paper coating process, coating the paper according to the common method, so that the coated paper contains phenolphthalein. The phenolphthalein is used for counterfeiting prevention, which belongs to a secondary relatively- covert chemical anti-counterfeiting means based on appliance verification, thus the law risk, counterfeiting difficulty and expected cost of counterfeiters are greatly increased, and a good anti-counterfeiting function is achieved.

Owner:无锡侨颂特种纸有限公司

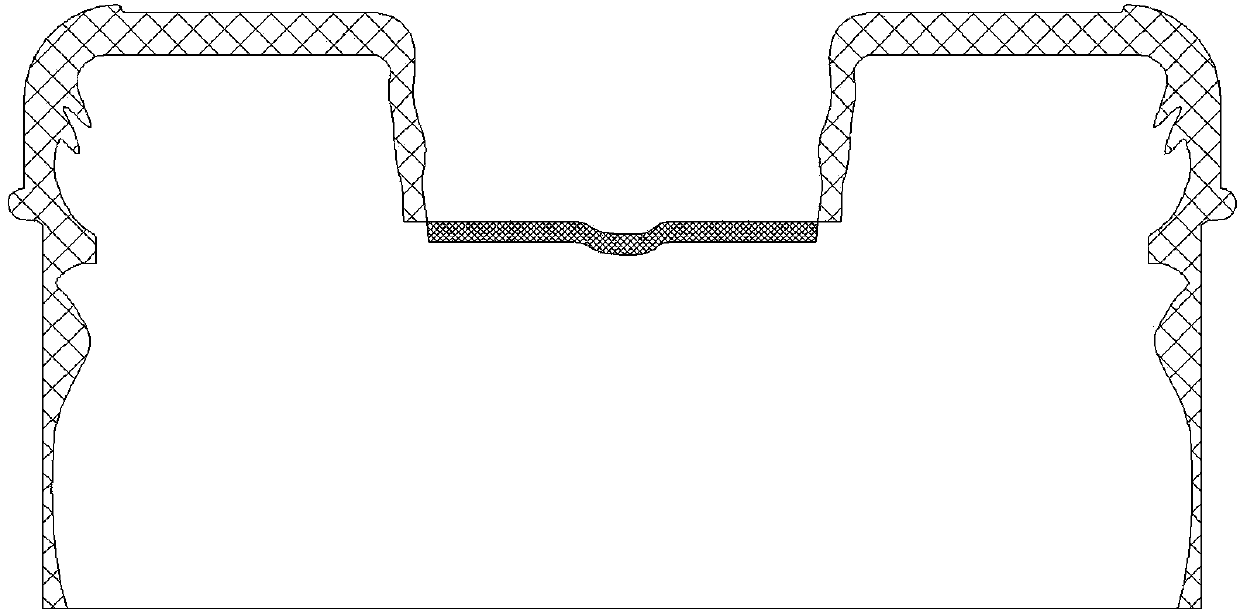

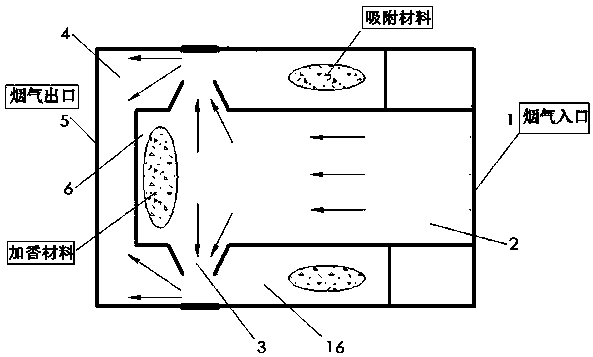

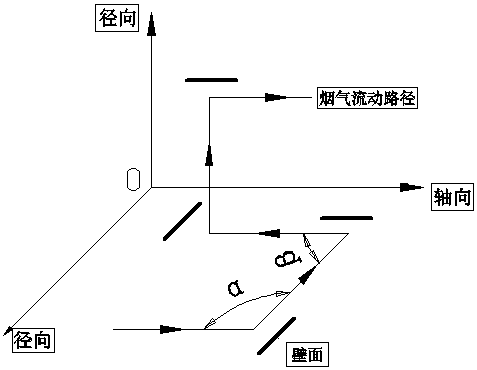

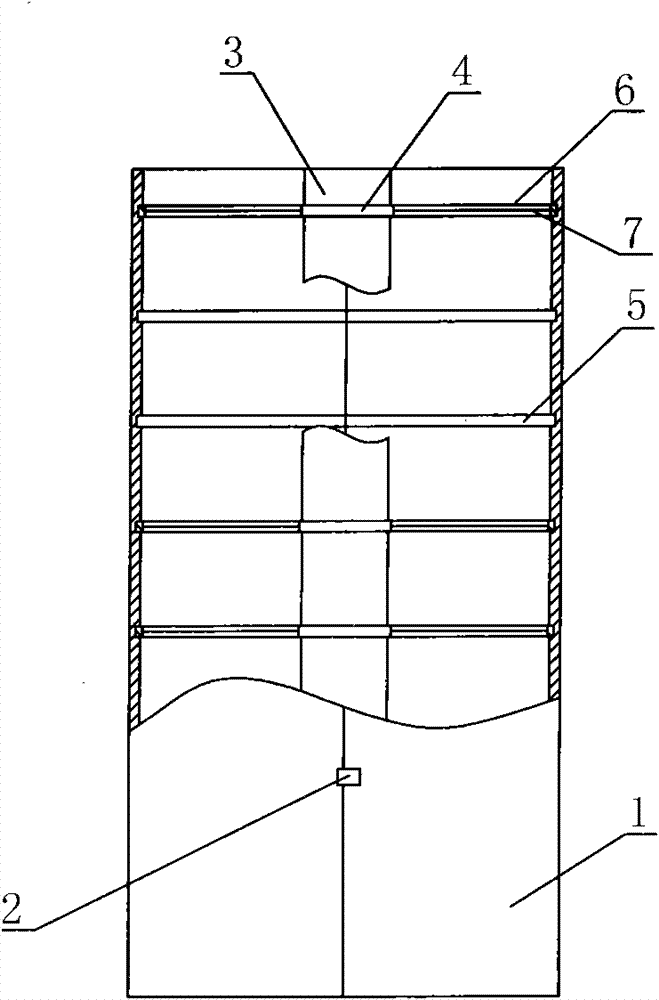

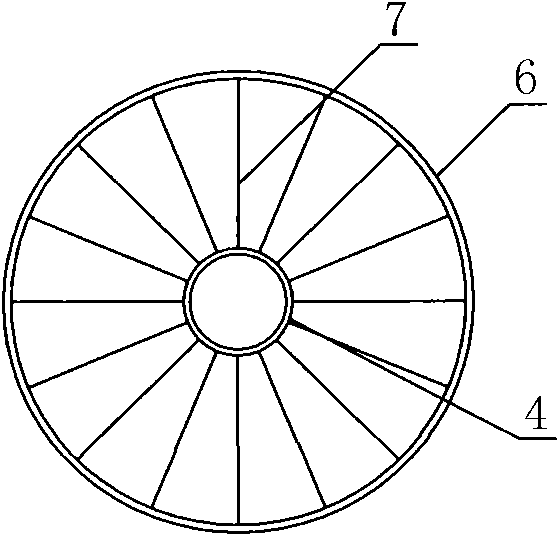

Compound filter stick with smoke veering function unit and cigarette filter tip of compound filter stick

The invention discloses a compound filter stick with a smoke veering function unit. One of units is the smoke veering function unit, the smoke veering function unit is internally provided with an axial airflow pipeline A, a turning airflow pipeline and an axial airflow pipeline B which are arranged in sequence, the turning airflow pipeline is preferentially a circular-truncated-cone-shaped pipeline, and particles can also be embedded in the tail end of the axial airflow pipeline A. A prepared cigarette filter tip can prolong a path of the smoke and improve the cooling effect on the smoke, hasthe functions of reducing tar and enhancing fragrance, improves the state of the smoke, and improves the sensory quality; or a visualized function unit is arranged, and can bring a direct sense of harm decreasing and tar reducing to consumers.

Owner:NANTONG CIGARETTE FILTER

Pattern processing method for polyurethane foam materials

The invention discloses a pattern processing method for polyurethane foam materials, belonging to the production field of polyurethane foam materials. The processing method comprises the following steps: firstly uniformly arranging a plurality of color lines with colors different from the colors of the polyurethane foam materials in a radial pattern in a color line frame, secondly uniformly installing the color line frame in a pattern processing frame, thirdly installing the pattern processing frame in a reactor, fourthly adding a uniform mixture of polyurethane particles, polyether, toluene diisocyanate and dichloromethane into the reactor, applying pressure to the reactor and taking out the samples after foaming for 1-2h and finally installing the samples and slicing the samples, wherein during taking out the samples, the color lines and the samples are integrated. Compared with the prior art, the pattern processing method is characterized in that the process is simple, the processing cost is low, the processed patterns on the foam materials have rules and good anti-counterfeiting function, etc.

Owner:山东绿色民足鞋业科技股份有限公司

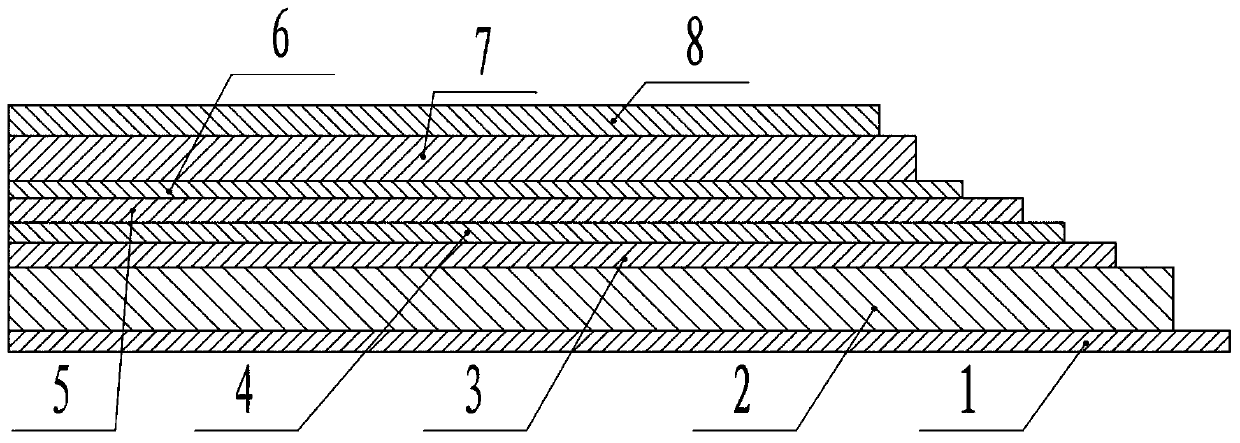

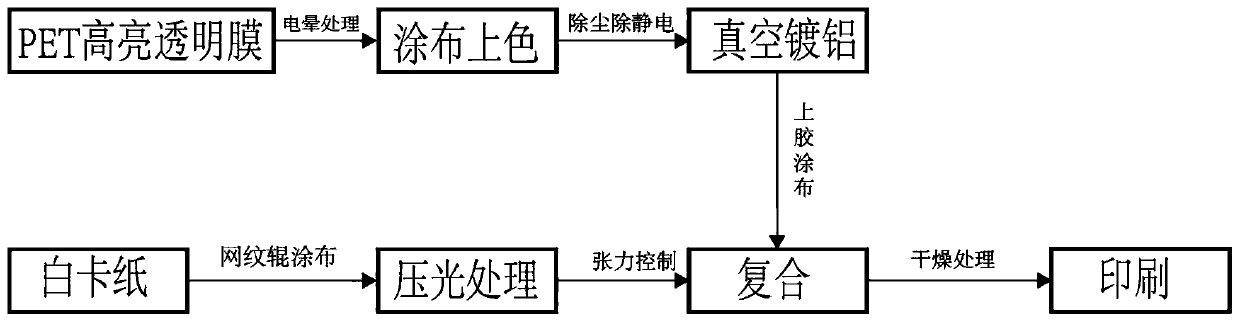

Black high-gloss composite paper gravure online printing structure and printing method thereof

PendingCN111469574AProcessability at the same timeSimultaneous printingDuplicating/marking methodsOther printing apparatusAdhesive gluePack material

The invention discloses a high-gloss transparent film black aluminum-plated composite paper gravure online printing structure and a printing method thereof. The printing structure comprises a back coating, a white card bottom layer, a calendered coating layer, a composite glue layer, an aluminum-plated layer, a black layer, a PET high-gloss film layer and a printing layer; the printing method comprises the steps of: carrying out double-sided corona treatment on the PET high-gloss transparent film; pre-coating the black bottom layer on the reverse side; carrying out vacuum aluminum plating to compound the PET high-gloss transparent film with bottom paper of which the surface is coated and calendered; and simultaneously thickening the back coating of the composite paper and sending to gravure equipment for online gravure printing to finally obtain a packaging material. According to the novel packaging material obtained by using the structure and method provided by the invention, the black layer of the black PET aluminum-plated composite paper is inside the PET film; the black layer structure can be protected by the PET film, so the novel packaging material is abrasion-resistant and scratch-resistant; scratches, stripping and the like are prevented during operation; and later processing operations are not affected.

Owner:贵州劲嘉新型包装材料有限公司

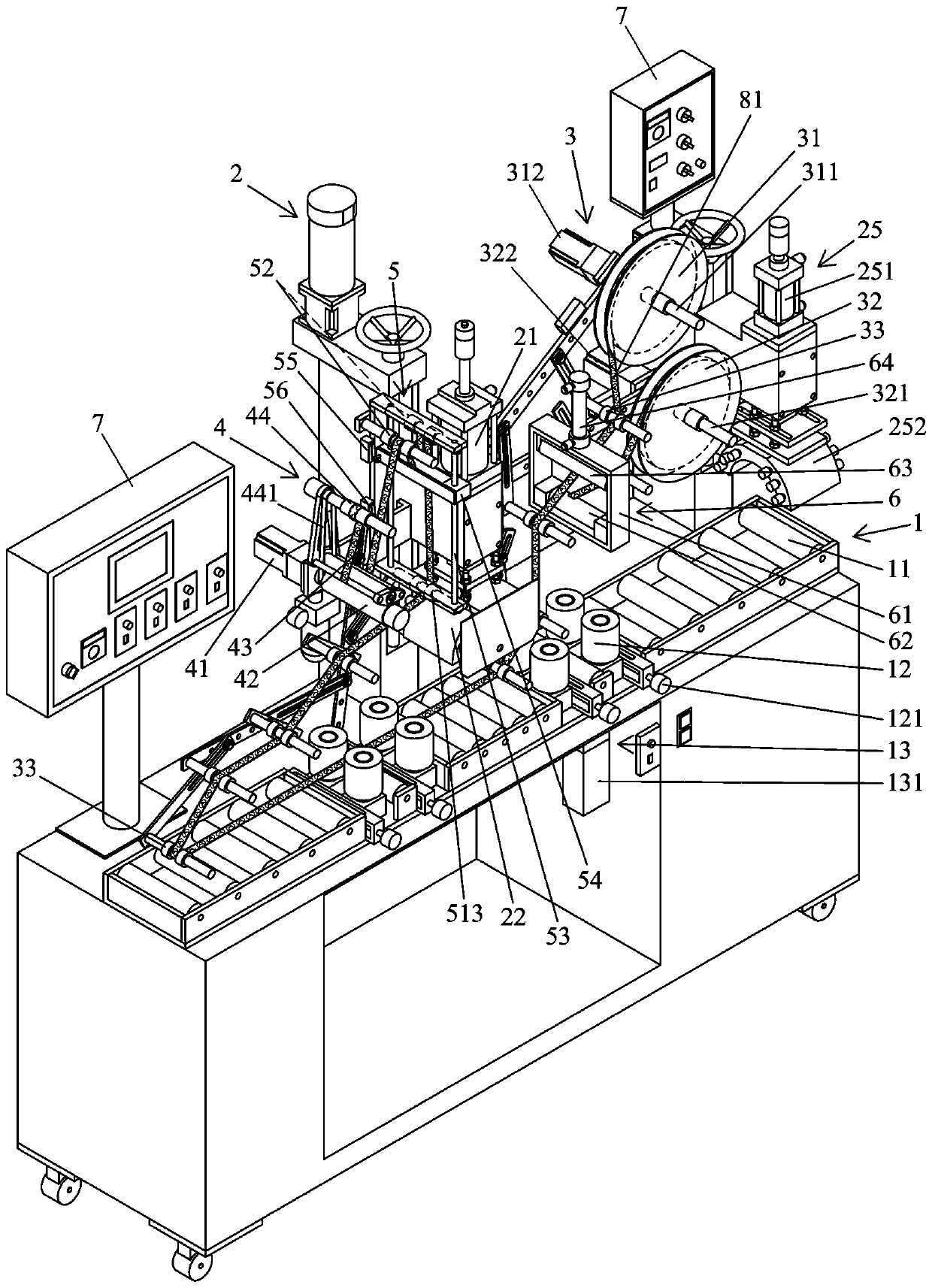

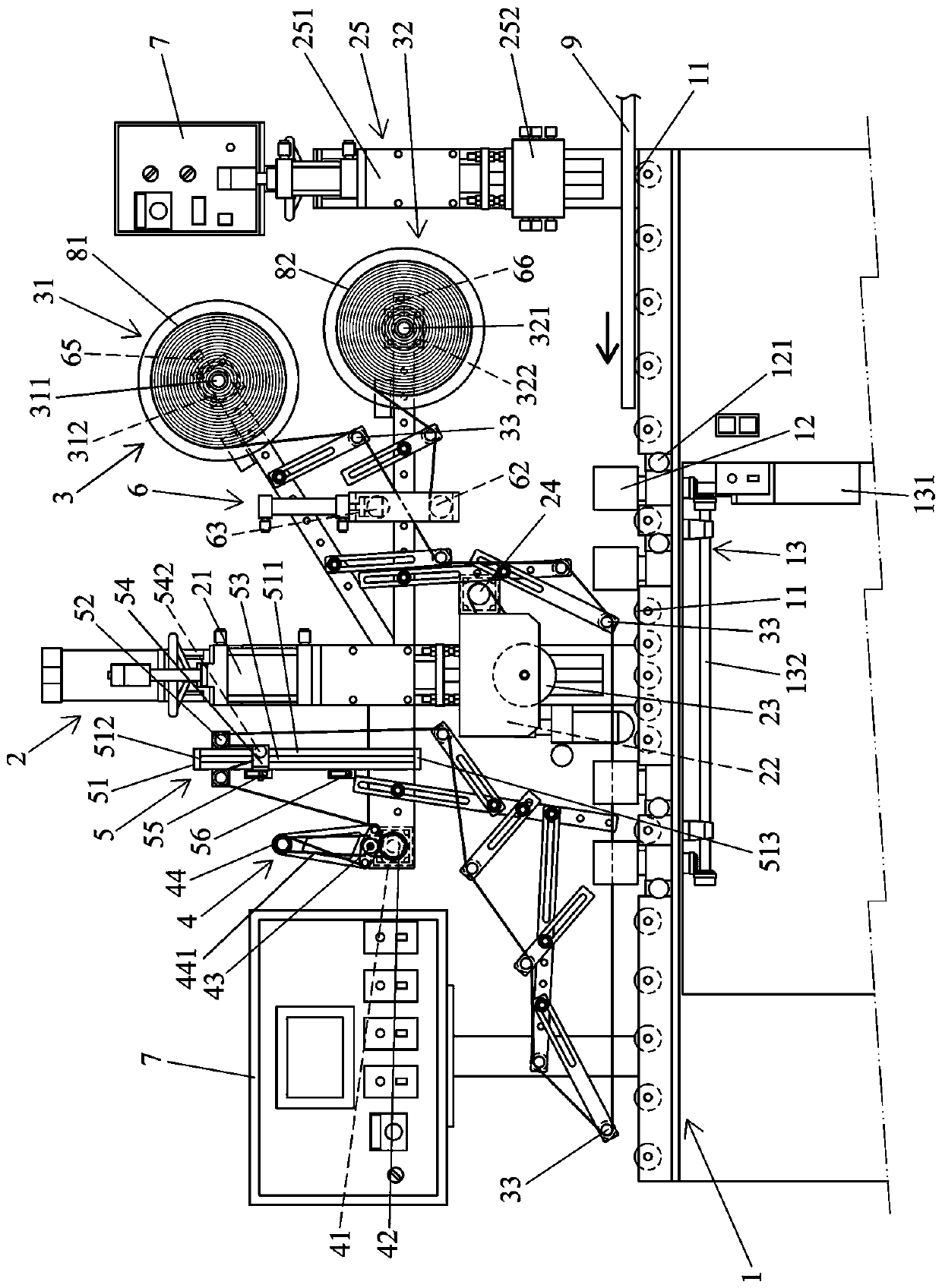

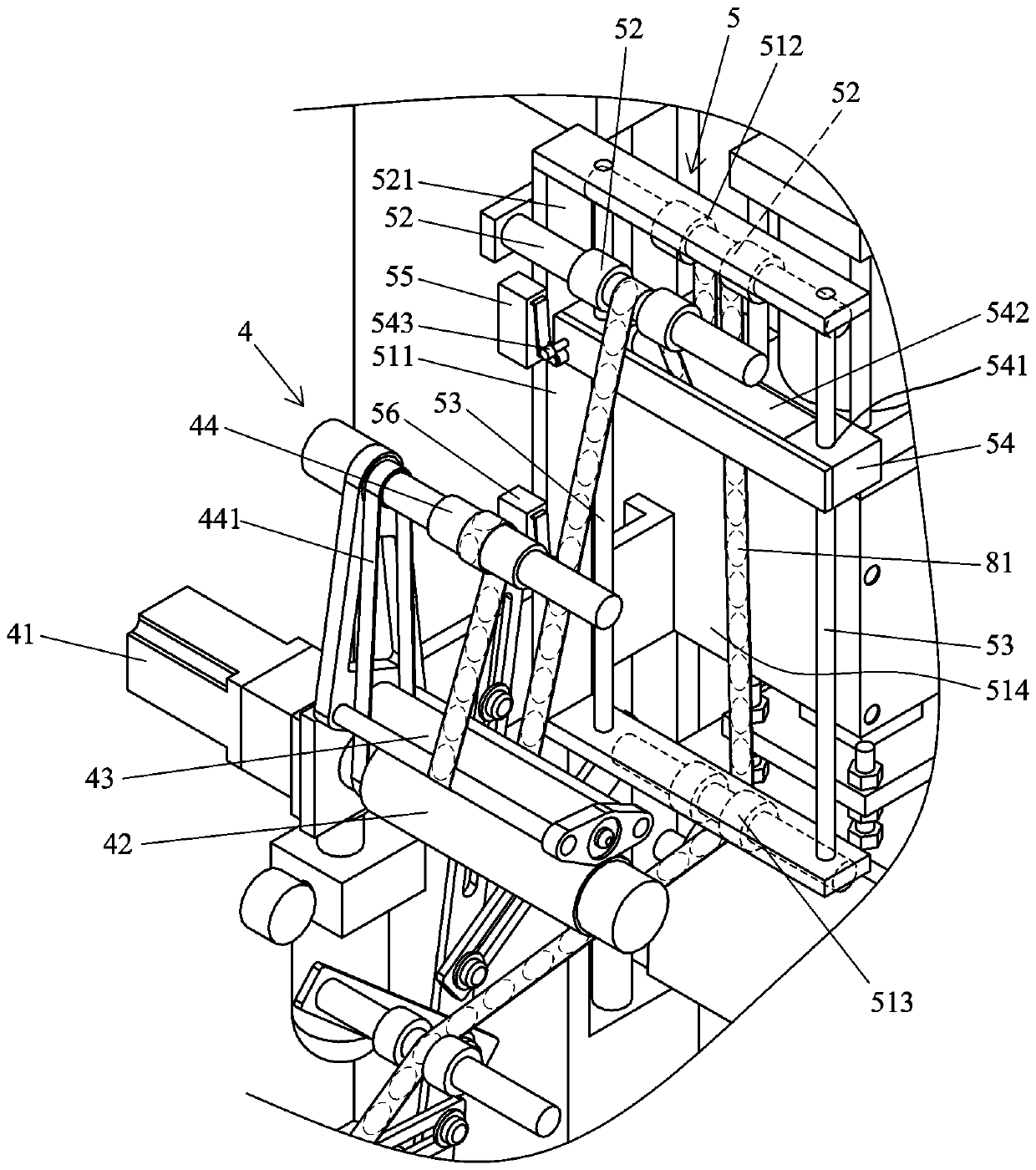

Method for setting marking pattern on surface of pipe, marking device and pipe

InactiveCN110682666AGood anti-counterfeiting functionFast printTransfer printingControl cellEmbossing

The invention discloses a method for setting a marking pattern on the surface of a pipe, a marking device and the pipe. The finished product of the pipe is provided with a plurality of continuous marking patterns on the outer surface by a heating printing method. The marking device comprises a conveying unit, a heating and embossing unit, a guiding unit, an actuating unit, an adjusting unit, a belt replacing unit and a control unit. A transfer belt can be set and the marking patterns on the transfer belt can be automatically and thermally printed on the outer surface of the pipe, so that better printing efficiency is achieved, and the outer surface of the pipe has continuous dense marking patterns to have anti-counterfeiting effects.

Owner:孙建杰

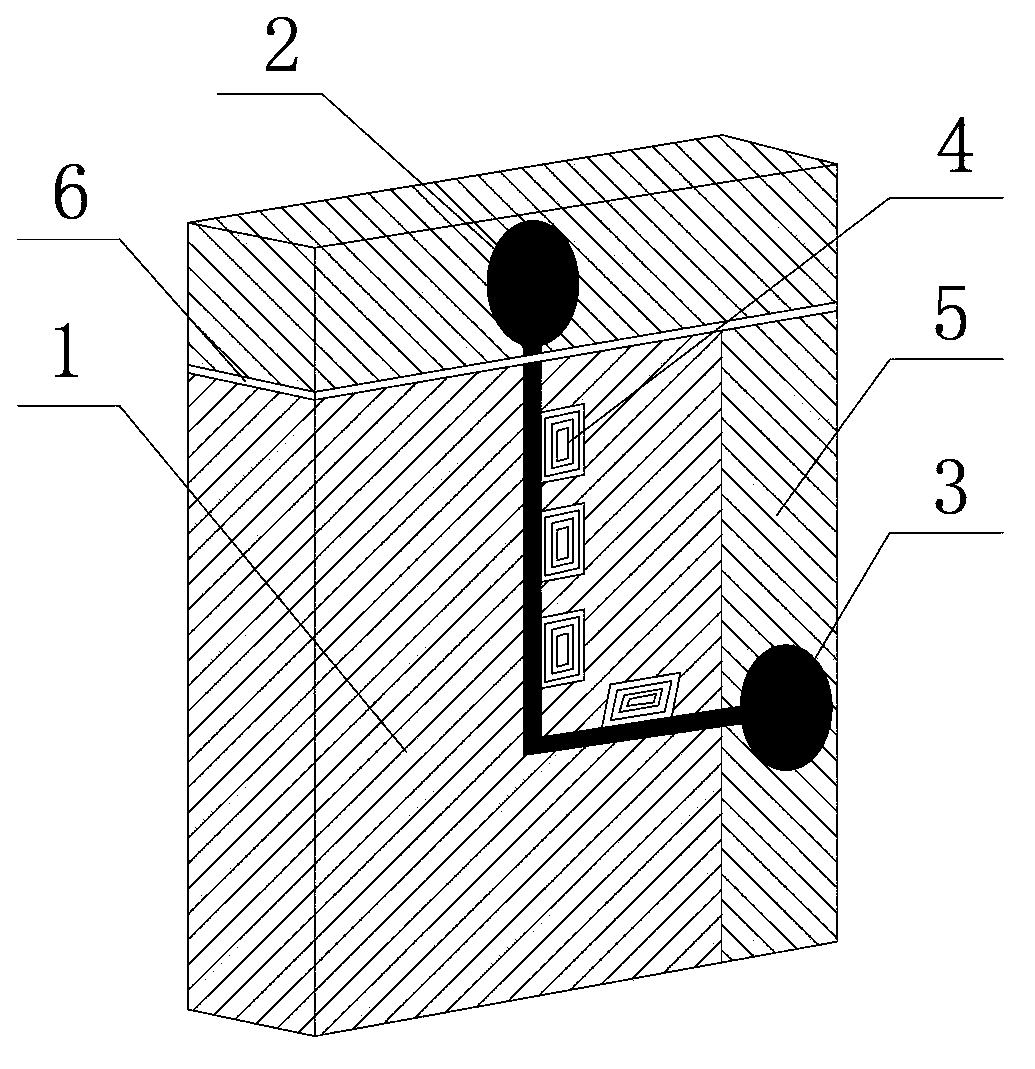

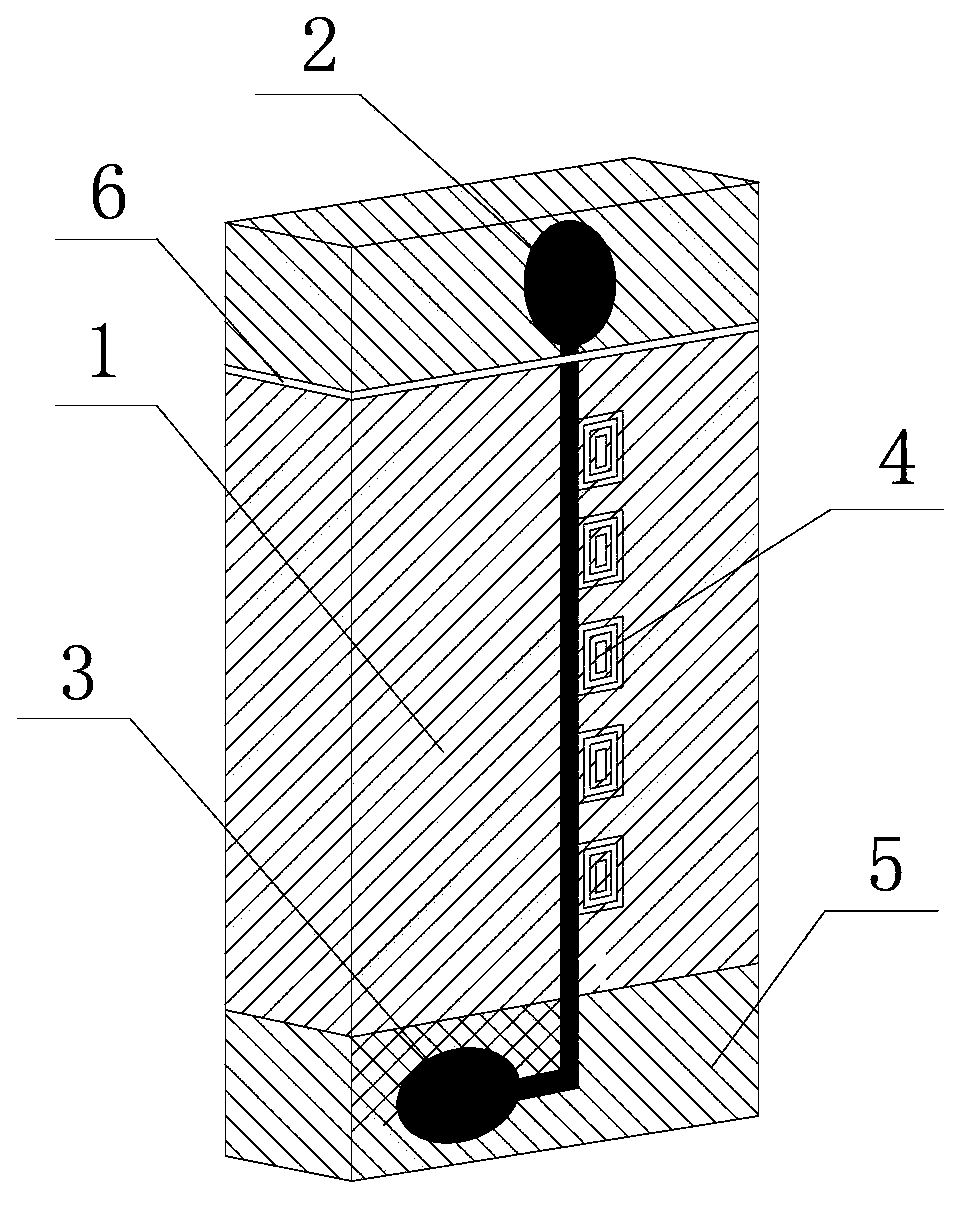

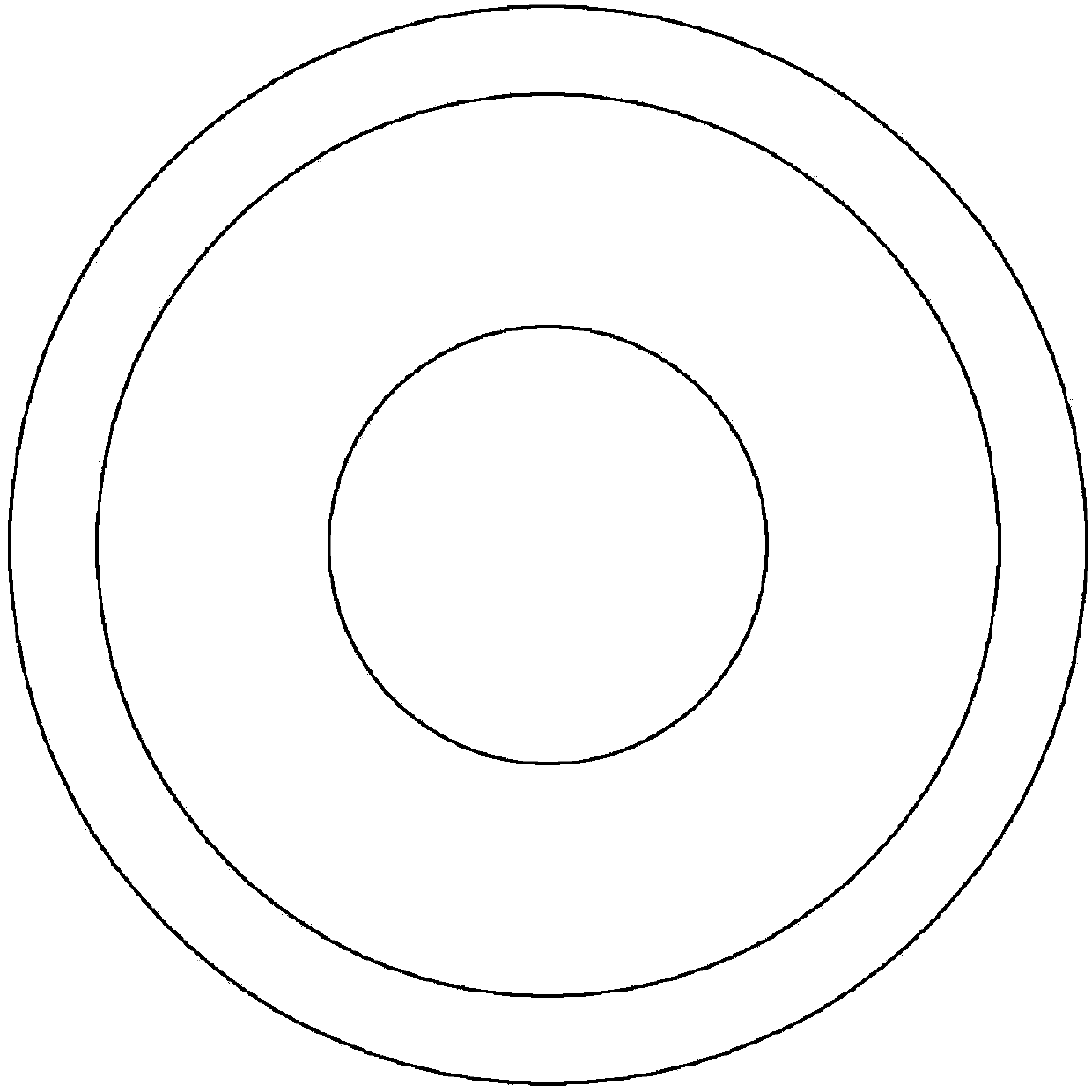

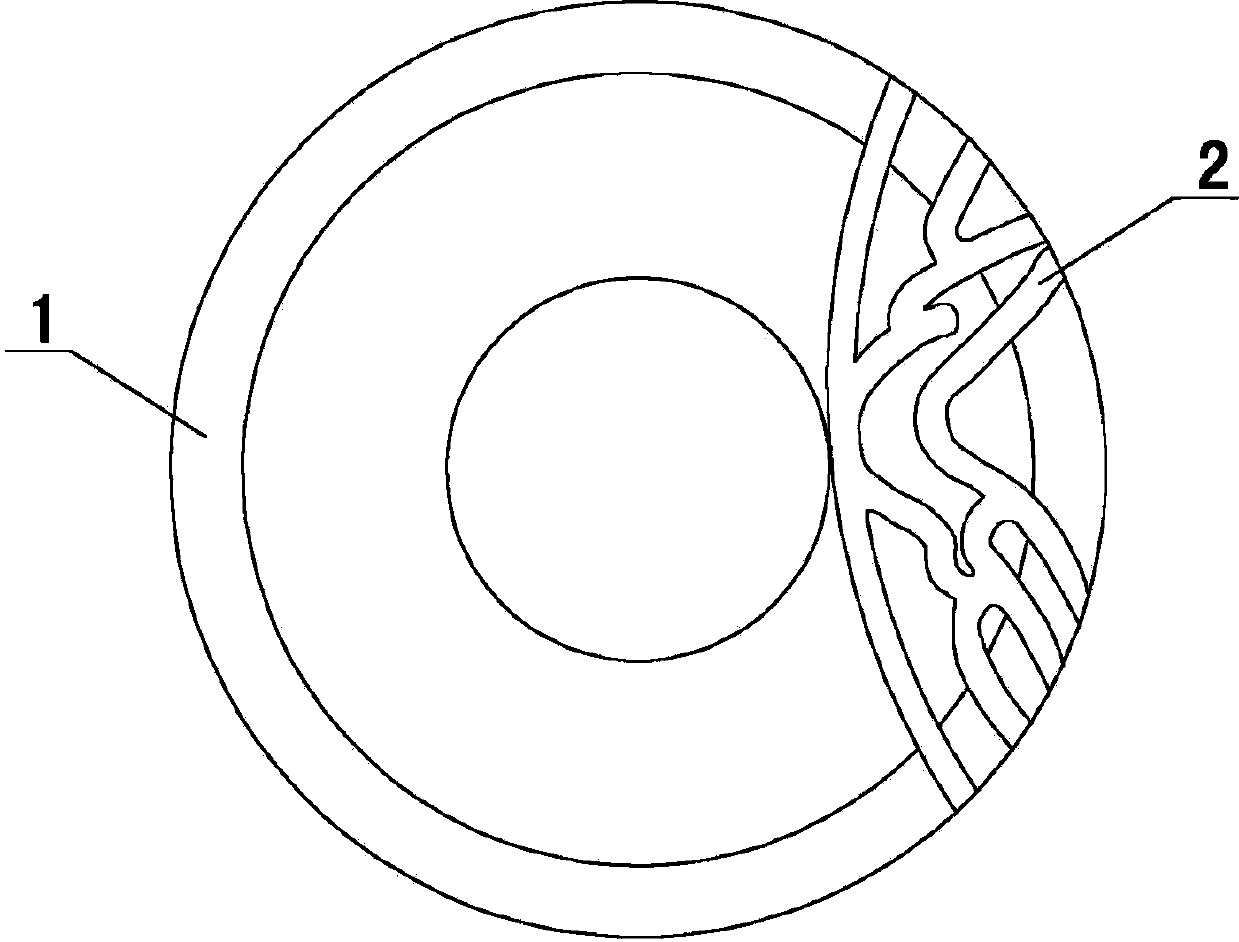

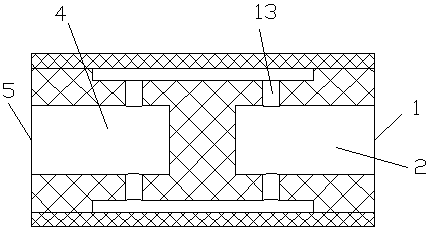

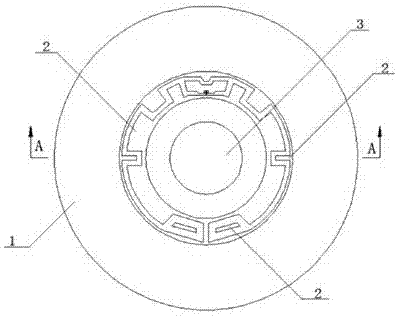

Embedded compact disc ultrahigh-frequency anti-counterfeit electronic label

InactiveCN107452406AEasy to identifyGood anti-counterfeiting functionRecord information storageRecording signal processingCompact discUltrahigh frequency

The invention discloses an embedded optical disc ultra-high frequency electronic label, which includes an optical disc and its central hole, and is characterized in that: in the non-data area outside the central hole of the optical disc, a ring-shaped ultra-high frequency electronic label is inlaid. Label. The UHF electronic tag is firmly packaged in two discs, and the relevant data in the electronic tag can be easily read within a range of 10cm with an UHF desktop reader, and has good wireless identification performance and anti-counterfeiting function. And, make optical disk have bright appearance, if want to replace this electronic label, then must pry open two sub-CDs, and pry open these two sub-CDs, this CD is also just rotten. Therefore, there is no risk of being replaced. Thereby, the recognition and anti-counterfeiting properties are greatly improved, and due contributions are made to safeguarding the rights of genuine CDs and cracking down on piracy.

Owner:周莉

Anti-counterfeiting magnetic printing ink for cigarette package bar code

The invention discloses anti-counterfeiting magnetic printing ink for a cigarette package bar code. The ink is prepared from the following ingredients in parts by weight: 25-45 parts of phenolic resin, 8-18 parts of silicone oil, 1-4 parts of 1,2-Bis(pentabromophenyl) ethane, 7-9 parts of active magnetic iron powder, 1.2-1.4 parts of tetrahydrofuran, 2-4 parts of tung oil, 1-2 parts of cobalt naphtenate, 2-3 parts of polysiloxane, 13-15 parts of N-methyl-2-pyrrolidone, 1-1.5 parts of melamine cyanurate, 4-6 parts of ninhydrin, 0.5-1 part of temperature-sensing toner, 0.1-0.5 part of nitrocotton, 0.5-1 part of zinc borate, 3-4 parts of glycerinum monomethyl acrylate, 1.6-2.4 parts of propylene glycol 1-monomethyl ether 2-acetate and 1-2 parts of erucyl amide. The ink disclosed by the invention has the advantages of simple preparation process, low production cost, good anti-counterfeiting function, is appropriate for printing various patterns and characters on plastics, paper and cloth,and can be used for simply and quickly identifying true and false products.

Owner:ANHUI SHUNTONG PACKAGING MATERIAL

A kind of organic long afterglow material and its preparation method and application

ActiveCN110079301BImprove flexibilityHigh transparencyLuminescent compositionsCarbazolePolyvinyl alcohol

The invention discloses an organic long afterglow material and its preparation method and application, comprising a host molecule and a guest molecule, the host molecule is carbazole, and the guest molecule is diphenylphosphonic acid anhydride. The guest molecule and the host molecule are mixed according to a certain mass ratio and then doped into the polyvinyl alcohol solution, and then coated on the substrate, and dried to form a film to obtain an organic room temperature phosphorescent material. The preparation method is simple and easy to control, and the composition Simple. The material has good flexibility and transparency, and the phosphorescence intensity and duration of carbazole are significantly improved by doping guest molecules, and the afterglow duration can reach 22s. At the same time, it realizes fluorescence emission and phosphorescence emission at room temperature, has a high degree of concealment, is convenient to use, and is easy to identify, thereby realizing a higher level of anti-counterfeiting function, and has a good application prospect in the fields of organic photoelectric materials and anti-counterfeiting encryption.

Owner:CHONGQING UNIV OF TECH

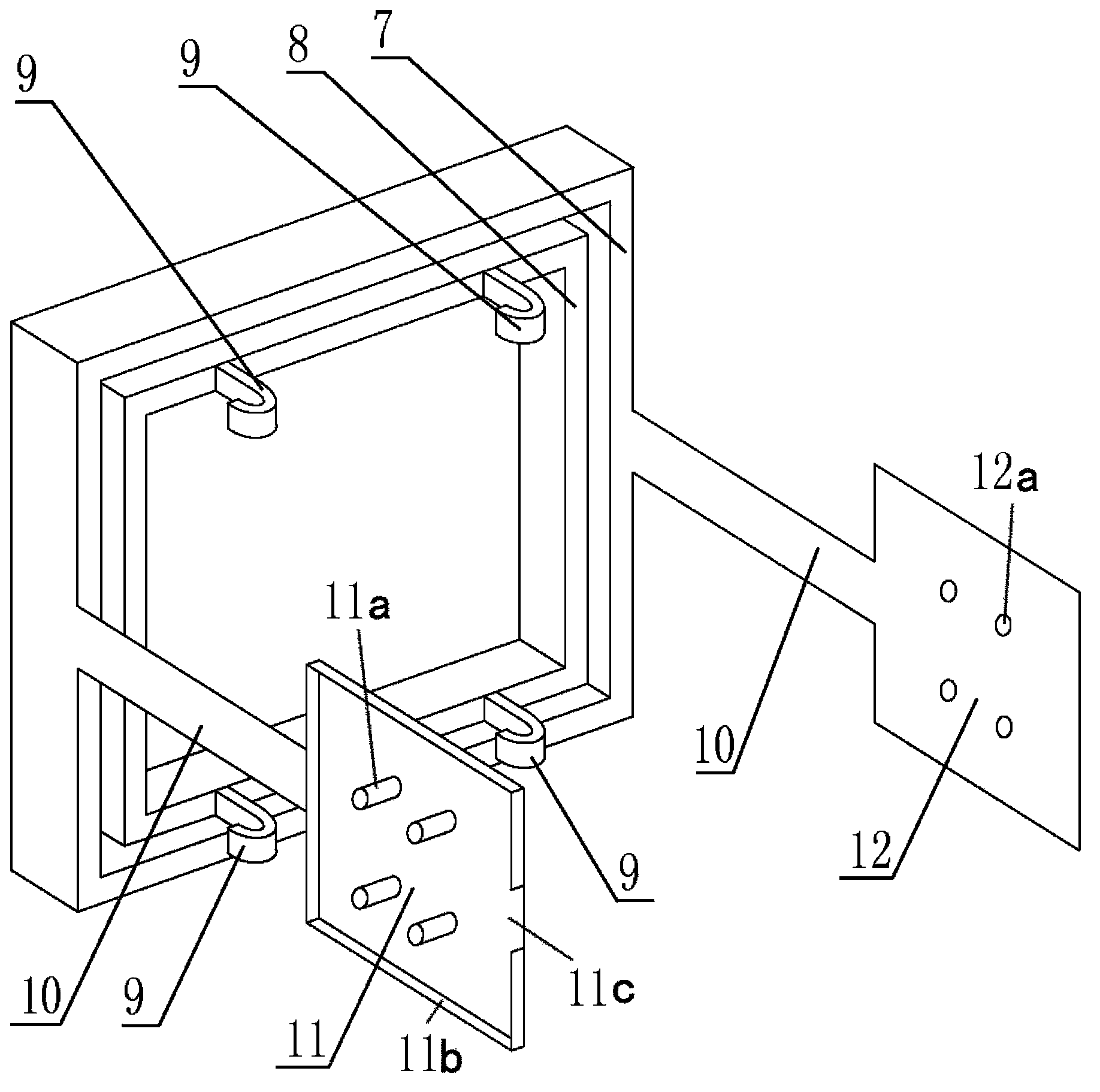

Packing case for suspending cargo in carton and packing method

ActiveCN102941975BSo as not to damageImprove shock absorptionContainers to prevent mechanical damageLocking devicesCartonEngineering

The invention discloses a packing case for suspending a cargo in a carton and a packing method. The packing case comprises a top cover, a bottom cover, a coverless carton, a cargo holding bag, a ribbon and the like, wherein the cargo holding bag is placed in the coverless carton; the top cover and the bottom cover are arranged at the two ends of the coverless carbon respectively; and the packing case is tightly sealed by using plastic tapes stamped with steel seals. According to the packing box and the packing method, a brand new high-efficiency cargo packing method is provided for sellers operating at an electronic commerce website.

Owner:尹宏

A kind of electroless aluminum bronzing product and its preparation process

ActiveCN107042723BImprove toughnessEasy to processNon-macromolecular adhesive additivesDecorative surface effectsHot stampingGraphics

The invention relates to the technical field of printing gold stamping, in particular to a non-alumite gold stamping product and a preparation process thereof. The preparation process of the non-alumite gold stamping product comprises the following steps that A, a combination plate is prepared, specifically, a gold stamping plate and a laser nickel plate with graphics and text information being carved are subjected to alignment and laminating through high temperature resistant glue to prepare the combination plate; B, paper is coated, specifically, the position, needing gold stamping, of the paper is coated with thermoplastic light oil or high-reflectivity coating to prepare a coating layer; and C, coating and gold stamping are conducted, specifically, the combination plate prepared in the step A is subjected to lock up and put on a machine, the coating layer prepared in the step B is pressed and subjected to gold stamping, and the non-alumite gold stamping product is prepared. The graphics and text information of the laser nickel plate can be printed on the paper in a hot stamping mode under the condition of no alumite medium, various laser effects can be shown on the paper through one procedure, the production cost is low, durability is good, the customization period is short, safety and environmental friendliness are achieved, and the multi-batch and small-amount production requirements are met.

Owner:HUCAIS PRINTING

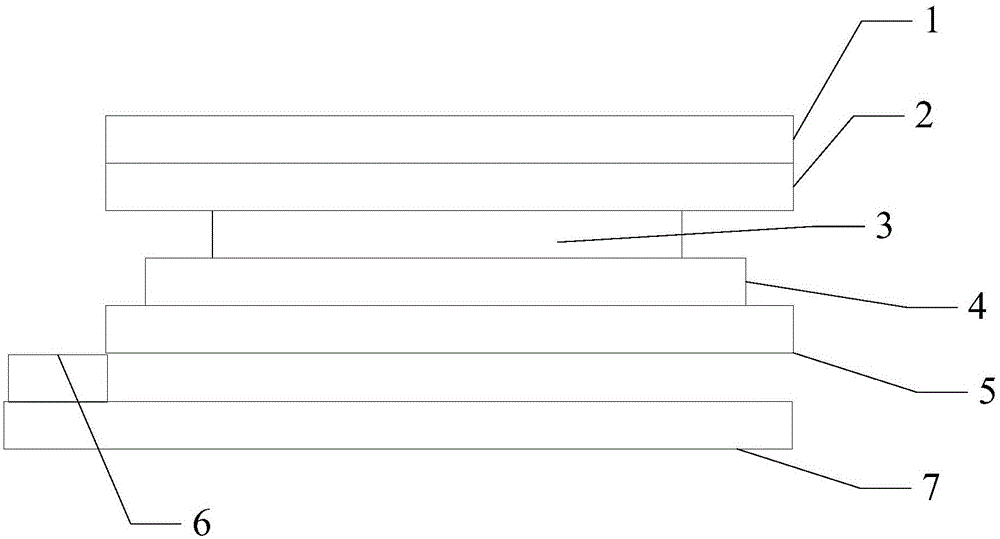

Manufacturing method of plastic flexible packaging bag with anti-counterfeiting mark

ActiveCN105109804BGood anti-counterfeiting functionFor long-term storageBagsSacksSurface layerEngineering

The invention discloses a plastic flexible packaging bag with an anti-counterfeit mark, comprising: a plastic surface layer; a mark attachment layer, which is coated on the lower surface of the plastic surface layer; a variable two-dimensional code mark layer, which is spray printed on the mark attachment layer The lower surface of the layer; the supporting layer, which is sprayed on the lower surface of the variable two-dimensional code marking layer to support the variable two-dimensional code marking layer; the plastic bottom layer, which is located on the lower surface of the supporting layer, and is attached to the plastic surface layer The variable barcode identification layer is attached to the lower surface of the plastic bottom layer and is located at the lower end of the identification attachment layer. The production batch number of the product is printed below the number of the variable barcode identification layer; the protective layer is located on the variable barcode identification layer. The lower surface of the layer is attached to the plastic surface layer. The present invention also provides a manufacturing method of the plastic flexible packaging bag. The anti-counterfeiting mark provided by the present invention is anti-destructive and anti-alteration, and is unique to the goods in the plastic flexible packaging bag, and has better Anti-counterfeiting function.

Owner:GUANGXI RONGXIAN FENGCAI PRINTING IND

A counterfeit detection method based on deep learning infrared detector

ActiveCN108335402BProcessing speedGood anti-counterfeiting functionPaper-money testing devicesCharacter and pattern recognitionLearning basedComputer science

The invention discloses a depth learning based and infrared geminate transistor employed authenticity identification method of a currency detector and belongs to a field of infrared authenticity identification. The method includes performing signal correctness verification according to multiple channels of infrared geminate transistor waveforms; performing pretreatment on the multiple channels ofthe infrared geminate transistor waveforms; generating a two-dimensional array, converting to an image and processing; performing currency authenticity identification by utilizing the infrared geminate transistor waveforms and adopting CNN training and a detection process in depth learning. The method provided by the invention can realize a good authenticity identification function at a comparatively high processing speed with high accuracy.

Owner:武汉卓目科技有限公司

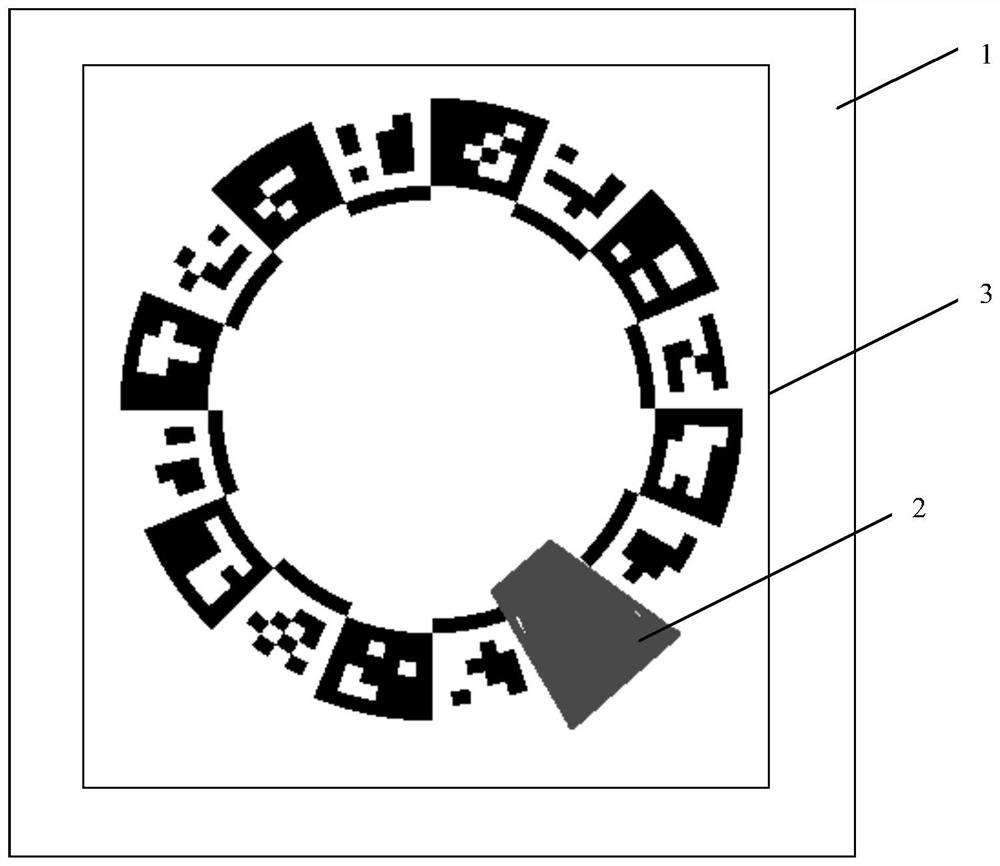

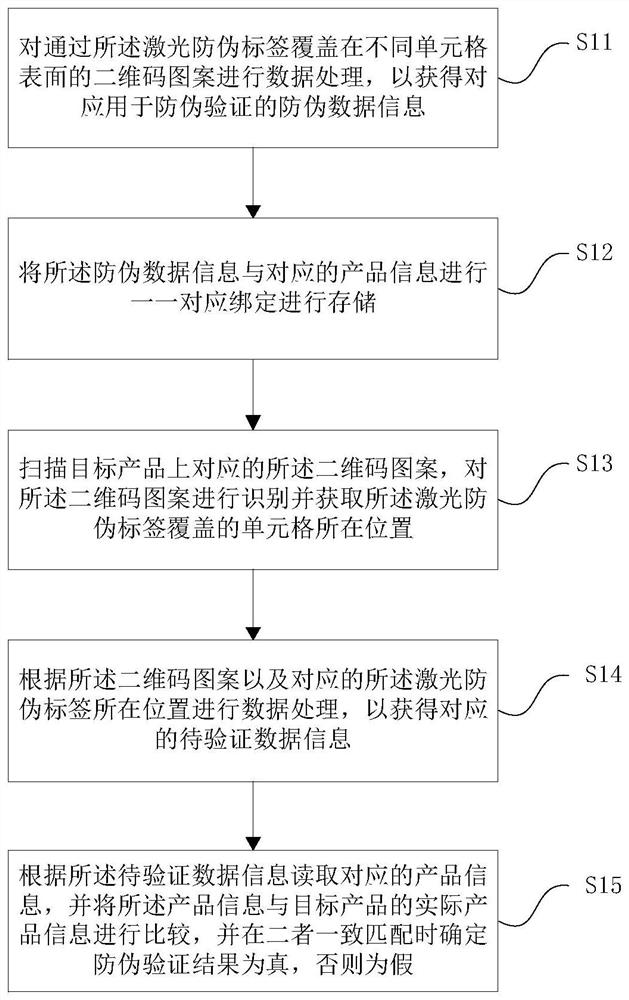

Anti-counterfeiting two-dimensional code and anti-counterfeiting verification method thereof

ActiveCN112132245ASolve technical problems that are easy to be copiedGood anti-counterfeiting functionCommerceRecord carriers used with machinesAlgorithmData information

The invention relates to an anti-counterfeiting two-dimensional code and an anti-counterfeiting verification method, the anti-counterfeiting two-dimensional code comprises a substrate layer and a laser anti-counterfeiting label, an area of a two-dimensional code pattern is printed on the substrate layer, the two-dimensional code pattern comprises a plurality of cells which are adjacently arrangedend to end in sequence and form an annular two-dimensional code pattern, and the laser anti-counterfeiting label is matched with the cells in shape. The laser anti-counterfeiting label covers the surface of the local cell, so that corresponding anti-counterfeiting data information for anti-counterfeiting verification is obtained when the two-dimensional code pattern of the cell covered with the laser anti-counterfeiting label is scanned. The cells in the two-dimensional code pattern are shielded through the laser anti-counterfeiting label, and anti-counterfeiting data information can be formedaccording to different shielding parts of the laser anti-counterfeiting label, so that the anti-counterfeiting information is conveniently associated with product information, the two-dimensional code pattern has a relatively good anti-counterfeiting function, the two-dimensional code pattern is not conveniently and randomly copied, the technical problem that the two-dimensional code is easy to copy is solved with low cost, and the anti-counterfeiting two-dimensional code is suitable for large-area popularization and application.

Owner:WUHAN SYSCAN TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com