Black high-gloss composite paper gravure online printing structure and printing method thereof

A printing method and composite paper technology, applied in the direction of copying/marking methods, printing, printing devices, etc., can solve the problems that the black layer cannot be protected by PET film, is prone to scratches, pulls, and affects processing operations, etc., to achieve richness The expression form of gravure printing technology, the effect of saving processing steps and enhancing competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

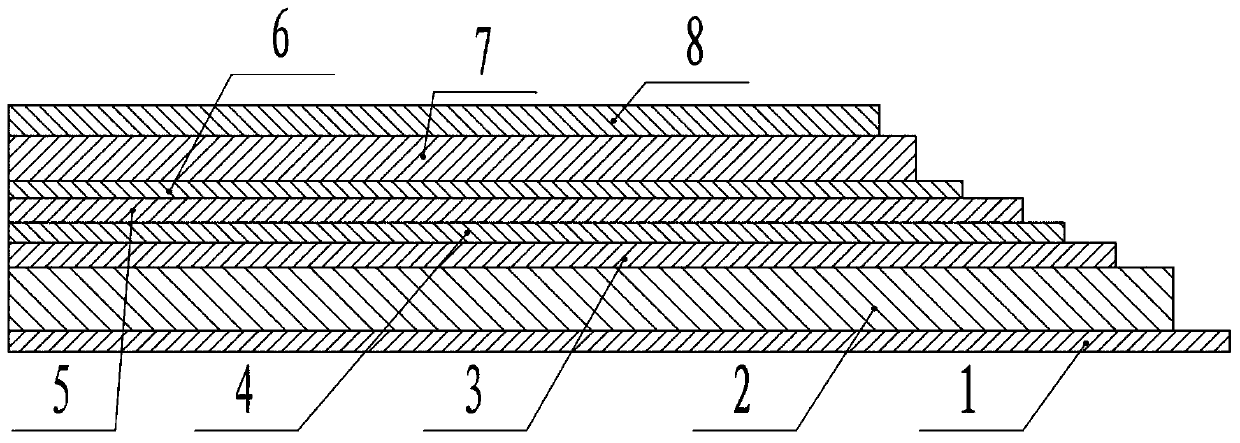

[0033] Embodiment 1: as figure 1 As shown, a high-gloss transparent film black aluminized composite paper gravure in-line printing structure, including from bottom to top back coating 2, white card bottom layer 2, calender coating layer 3, composite glue layer 4, vacuum Aluminum layer 5, black layer 6, PET highlight film layer 7 and printing layer 8.

Embodiment 2

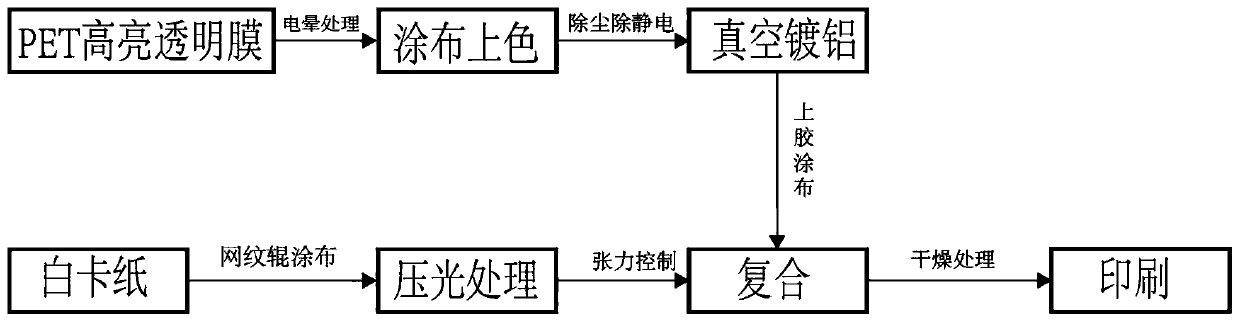

[0034] Embodiment 2: as figure 2 As shown, a printing method of a high-gloss transparent film black aluminized composite paper gravure printing in-line printing structure, the method is: pre-coat a layer of black background color on the reverse side of the PET high-gloss transparent film, first vacuum aluminized, and then Combining it with the base paper that has been surface-coated and calendered, a new packaging material with a multi-layer structure and a high-gloss mirror effect is obtained.

[0035] At present, the general production mode in the packaging and printing industry is: paper-making enterprises use professional laminating machines to produce aluminized composite paper, and printing companies outsource finished paper for printing. Due to the limitation of production equipment, it is often difficult for printing companies to break out of the traditional process thinking. The equipment used in the present invention is the Cerudy R960 gravure printing unit, which ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com