Printing equipment for capacitor processing

A capacitor processing and printing equipment technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of low efficiency and high production cost, achieve high efficiency, low production and use costs, and meet the needs of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

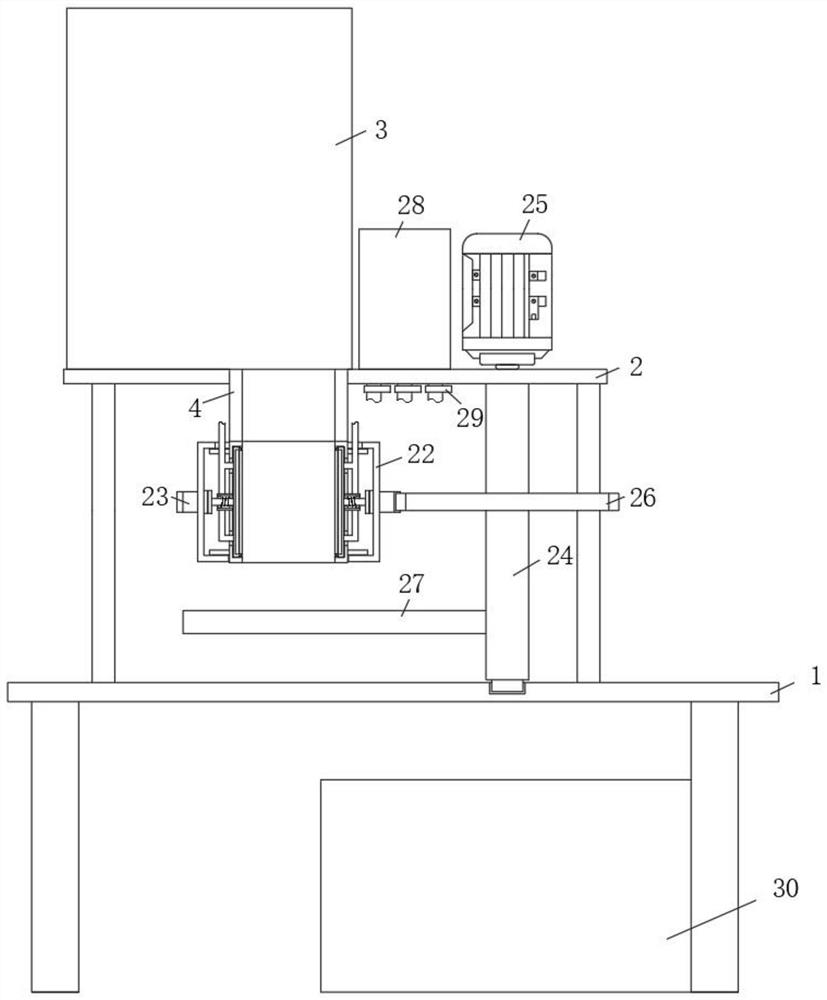

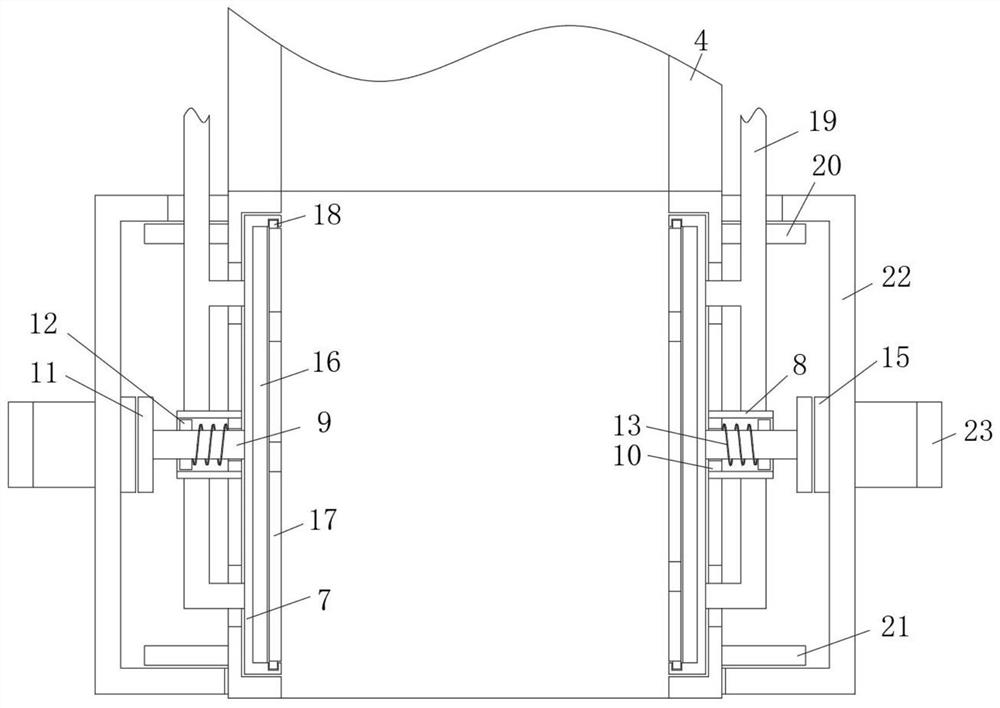

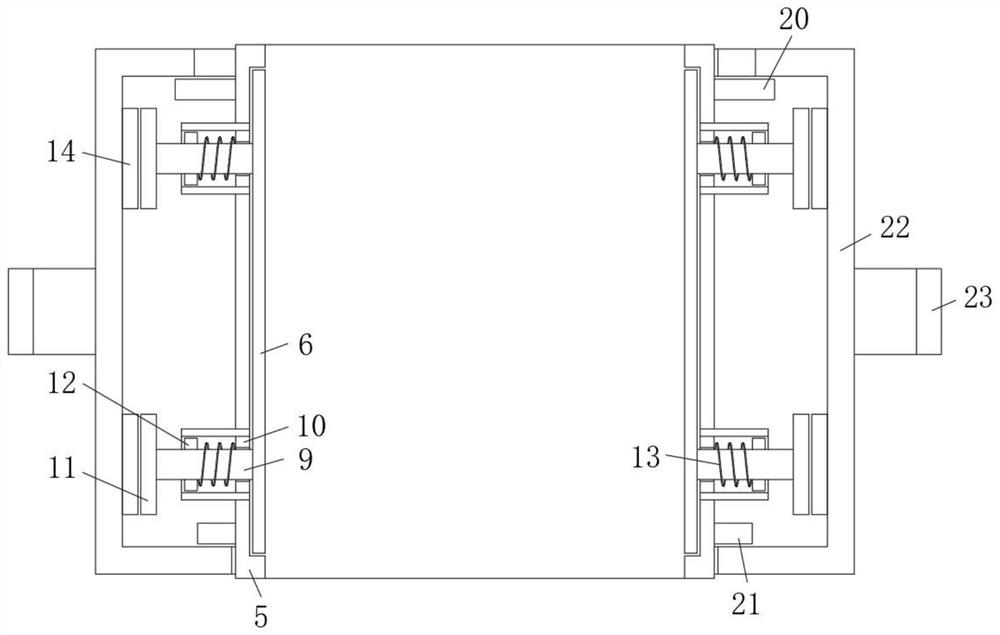

[0029] refer to Figure 1-4 , a kind of printing equipment for capacitor processing, comprising a workbench 1, the top of the workbench 1 is fixed with a stand 2, the top of the stand 2 is equipped with a feeding tray 3, and the bottom outlet of the feeding tray 3 is connected with a discharge pipe 4. The bottom of the feeding pipe 4 is provided with a printing mechanism. The printing mechanism includes a processing end pipe 5 fixedly connected to the bottom of the feeding pipe 4. The body of the processing end pipe 5 is provided with side grooves 1 and 2, side groove 1 and There are multiple side slots 2, and they are set at equal intervals. A capacitor clamping mechanism is arranged in the side slot 1, and a printing mechanism is arranged in the side slot 2. The capacitor clamping mechanism includes a positioning bead vertically arranged in the side slot 1. 6. The printing mechanism includes printing strips 7 vertically arranged in the second side slot. A placement groove is...

Embodiment 2

[0032] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the ink supply mechanism includes a liquid storage tank 28 fixedly installed on the top side of the platform 2, and a liquid inlet pipe 19 is fixedly connected to the vertical side of the printing strip 7 to feed The top of the liquid pipe 19 communicates with the bottom of the liquid storage tank 28 , and the pipe body of the liquid inlet pipe 19 is provided with a valve 29 .

[0033]In this embodiment, the arrangement of the ink supply mechanism completes the replenishment and control of the amount of ink in the liquid storage sliver 16 and ensures the continuity of printing.

Embodiment 3

[0035] Such as Figure 1-4 As shown, this embodiment is basically the same as Embodiment 1. Preferably, the top inner wall and the bottom inner wall of the printing strip 7 are provided with card slots, and the two ends of the hollowed-out printing plate 17 are fixedly connected to the card blocks 18 and are respectively clamped on the card slot.

[0036] In this embodiment, when printing capacitors with different contents, select the corresponding hollowed-out printed board 17 for replacement and installation. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com