Rolling printing device for metal coil and rolling printing method for metal coil

A metal coil and coil technology, which is applied in the directions of printing devices, printing, printing machines, etc., can solve the problems of inability to realize continuous whole-roll substrate printing, inability to realize pattern printing, insufficient aesthetics, etc., and achieve good visual appearance and anti-counterfeiting. function, improve the shortcomings of sheet-fed flat printing, and fill in the effect of technical gaps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

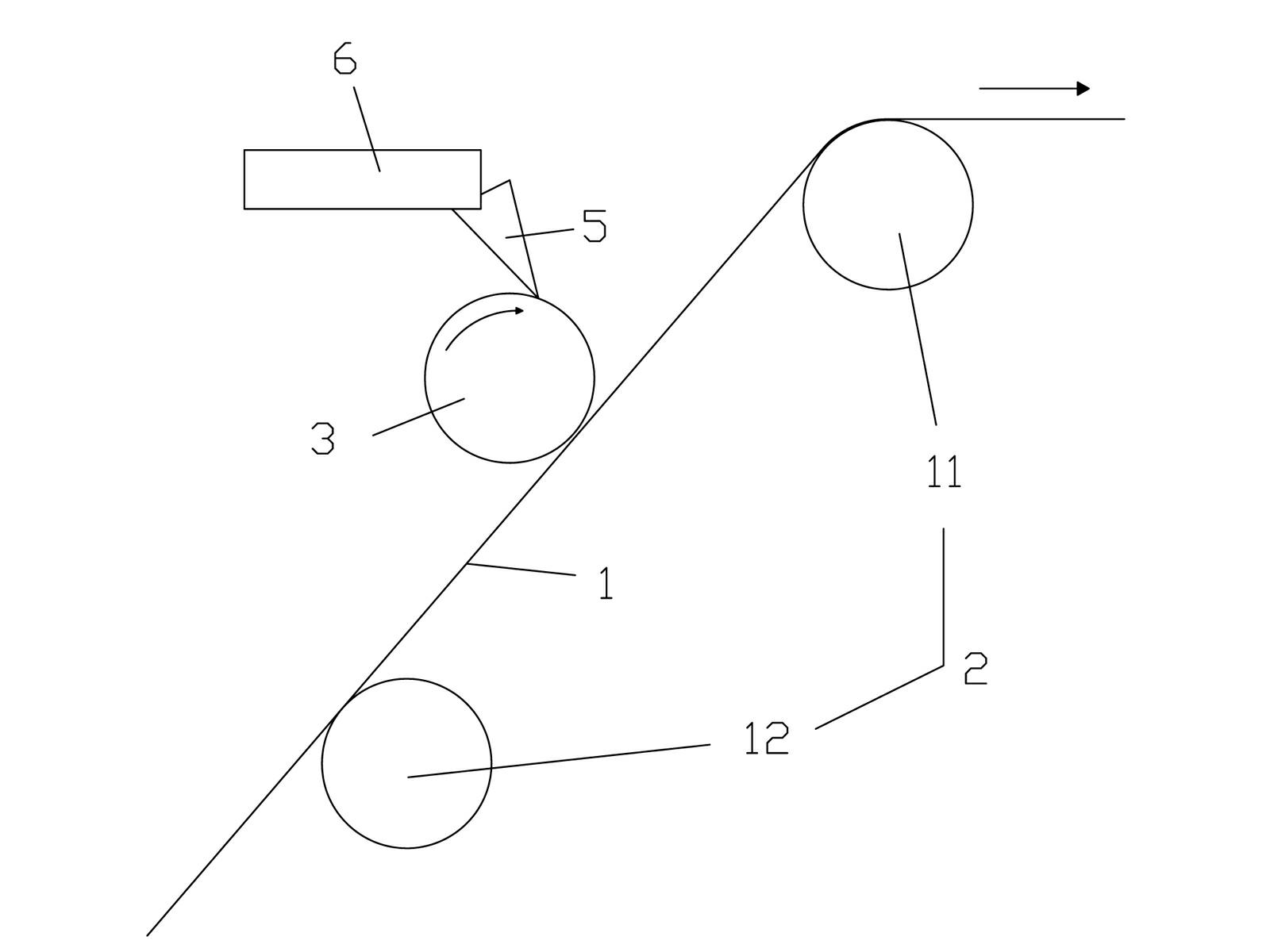

[0018] refer to figure 1 , the metal coil printing device includes: a support 2, a coil substrate 1 is arranged on the support 2, and the coil substrate 1 moves on the support 2, and the movement of the coil substrate 1 can be carried out by various common driving parts Drive implementation; rotatable printing roller 3, the surface of the printing roller 3 is engraved with printing patterns, and the surface of the printing roller 3 is abutted against the coil substrate 1; it is used to add printing material to the printing roller 3 Material filling part 4. In this embodiment, the printing material filling part 4 includes a printing material tank 6 and a scraper 5, and the printing material in the printing material tank 6 is scraped onto the printing roller 4 by the doctor blade 5. The realization of this printing material filling part 4 The method is relatively simple, and the filling effect can meet the needs of basic production. The support member 2 includes a left support...

Embodiment 2

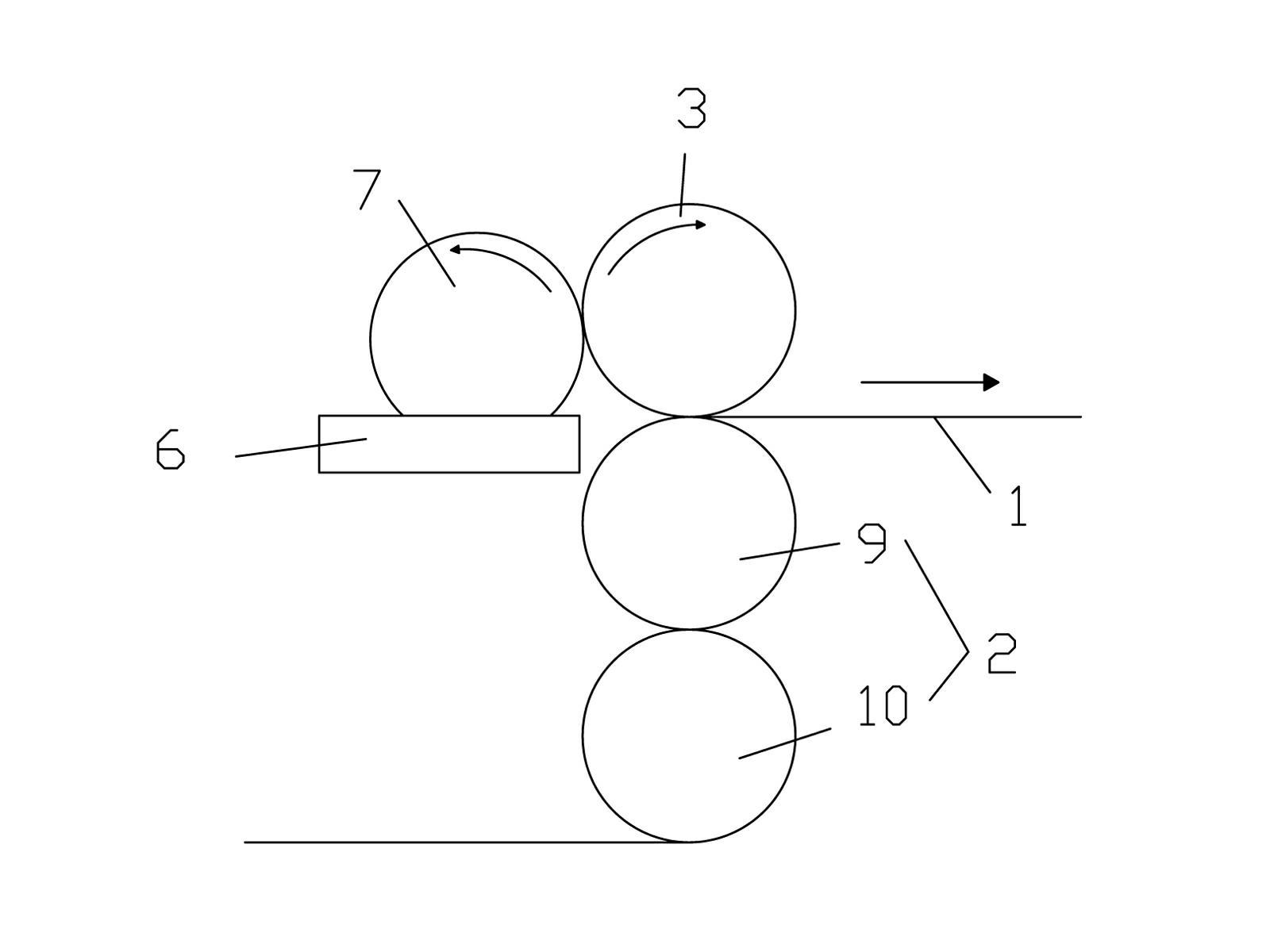

[0020] refer to figure 2 The printing material filling part 4 of this embodiment includes a printing material tank 6 and a bonding roller 7 , the bonding material roller 7 rotates in the groove of the printing material tank 6 , and the surface of the bonding material roller 7 is in close contact with the printing roller 3 . Compared with the first embodiment, this way of filling the printing material can achieve a relatively uniform filling effect, and the control of the rotation of the adhesive roller 7 is more convenient than the control of the scraper. The support member 2 of this embodiment includes an upper supporting roller 9 and a lower supporting roller 10 arranged vertically up and down and close to each other, and the coil substrate 1 is wound on the upper supporting roller 9 and the lower supporting roller in an "S" shape. 10, the arrangement of the upper support roller 9 and the lower support roller 10 allows the coil substrate 1 to pass between the two support ro...

Embodiment 3

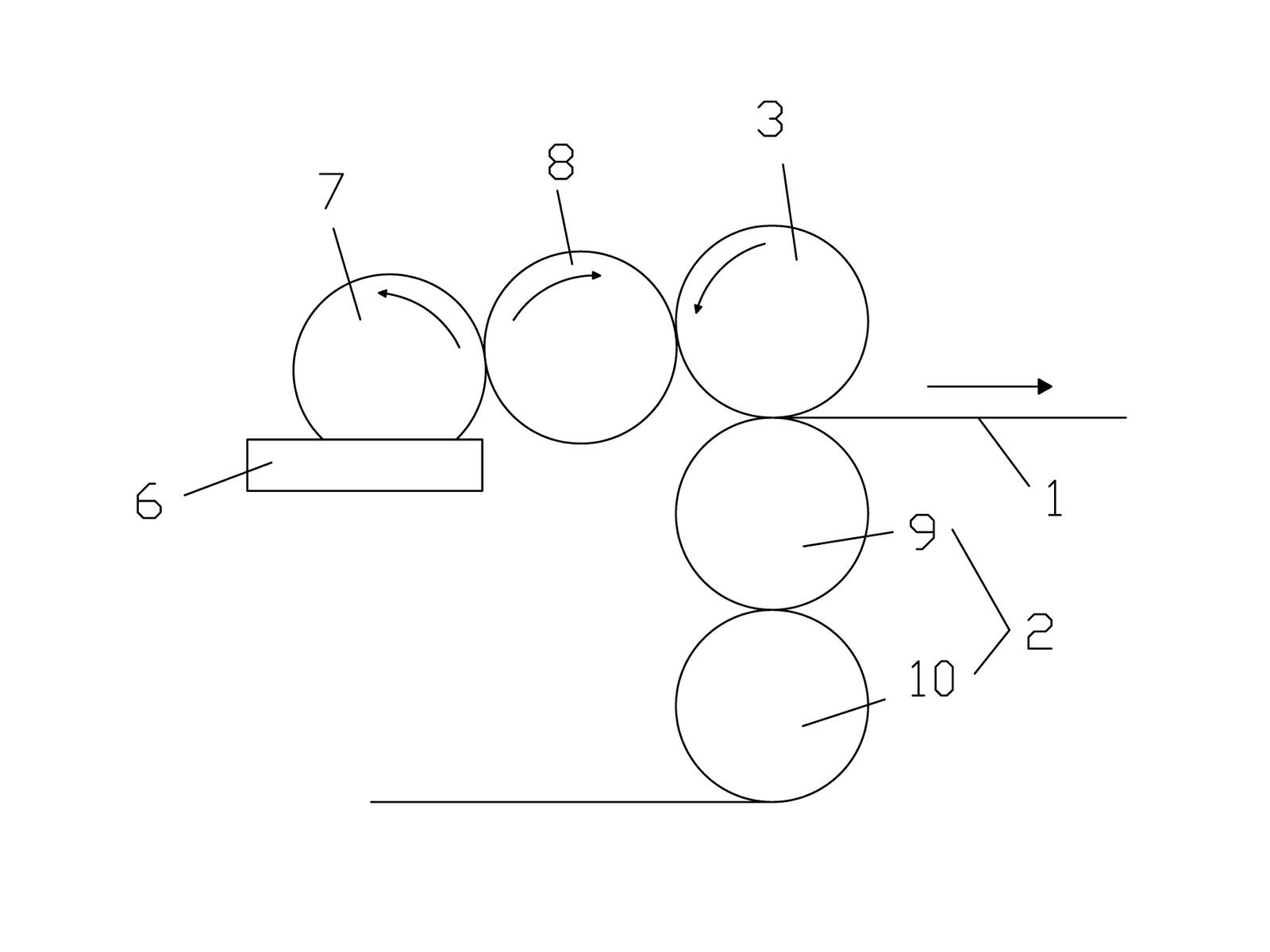

[0022] refer to image 3 The printing material filling part 4 of the present embodiment includes a printing material tank 6, a bonding material roller 7 and a transfer roller 8, the bonding material roller 7 rotates in the groove of the printing material tank 6, and the surface of the transferring material roller 8 is respectively connected to the bonding material. Material roller 7 and printing roller 3 are close to each other. Compared with the second embodiment, the structure of this printing material filling part 4 increases the middle transfer roller 8, and the setting of the transfer roller 8 can further increase the uniformity of the printing material on the printing roller, and prevent the adhesive roller 7 from printing the material tank. 6 After the adhesive is applied, it is directly coated on the printing roller 3 without treatment. Regarding the arrangement of the supporting member and the printing roller, this embodiment adopts the same setting method as that of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com