A kind of electroless aluminum bronzing product and its preparation process

An anodized aluminum and hot stamping technology, which is applied in the field of printing hot stamping, can solve the problems of hot stamping products such as pasting, wrinkling of anodized aluminum, and blurred outlines of graphics and texts, so as to avoid uneven surfaces, avoid waste and pollution, and improve registration and lamination degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

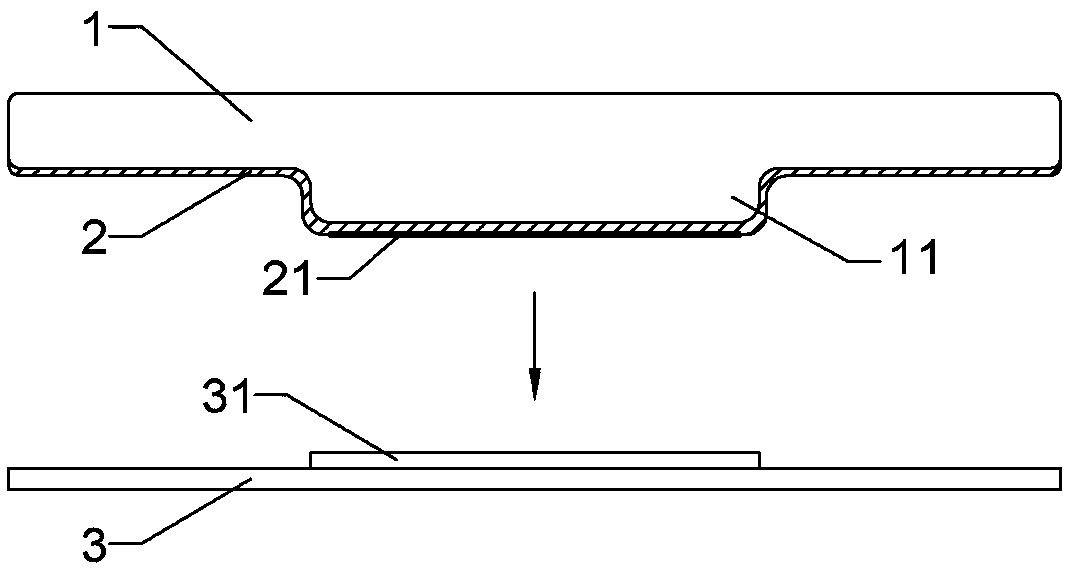

[0051] as attached figure 1 Shown, a kind of electroless aluminum bronzing process comprises the steps:

[0052] A. Preparation of combined version: use high temperature resistant glue to bond hot stamping version 1 and laser nickel version 2 engraved with graphic information 21 with registration to make a combined version;

[0053] B. Paper coating: apply thermoplastic varnish or high-reflective paint to the position of the paper 3 that needs to be bronzed to obtain the coating layer 31;

[0054] C. Coating bronzing: the combined plate prepared in step A is loaded on the machine, and the coated layer 31 prepared in step B is pressed and bronzed to obtain an electroless aluminum bronzing product.

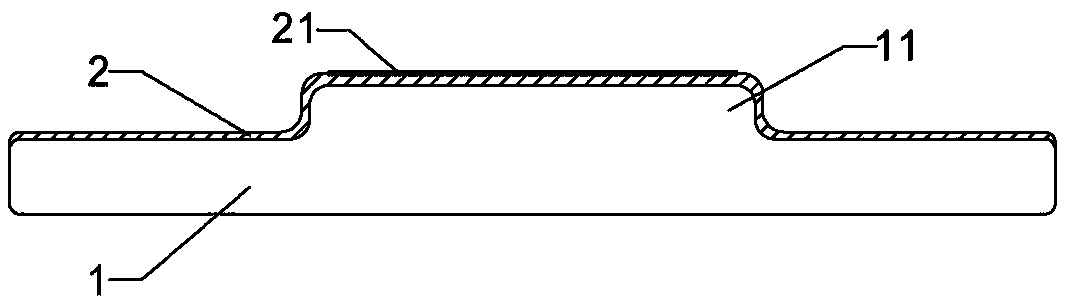

[0055] as attached Figure 1-2 As shown, the middle part of the hot stamping plate 1 is provided with a boss 11, and the graphic information 21 of the laser nickel plate 2 corresponds to the boss 11 of the hot stamping plate 1, and they are aligned and bonded together.

[0056] I...

Embodiment 2

[0074] The difference between this embodiment and above-mentioned embodiment 1 is:

[0075] An electroless aluminum bronzing process, comprising the steps of:

[0076] A. Preparation of combined version: use high temperature resistant glue to bond hot stamping version 1 and laser nickel version 2 engraved with graphic information 21 with registration to make a combined version;

[0077] B. Paper coating: apply thermoplastic varnish or high-reflective paint to the position of the paper 3 that needs to be bronzed to obtain the coating layer 31;

[0078] C. Coating bronzing: the combined plate prepared in step A is loaded on the machine, and the coated layer 31 prepared in step B is pressed and bronzed to obtain an electroless aluminum bronzing product.

[0079] as attached Figure 1-2 As shown, the middle part of the hot stamping plate 1 is provided with a boss 11, and the graphic information 21 of the laser nickel plate 2 corresponds to the boss 11 of the hot stamping plate 1...

Embodiment 3

[0098] The difference between this embodiment and above-mentioned embodiment 1 is:

[0099] A. Preparation of combined version: use high temperature resistant glue to bond hot stamping version 1 and laser nickel version 2 engraved with graphic information 21 with registration to make a combined version;

[0100] B. Paper coating: apply thermoplastic varnish or high-reflective paint to the position of the paper 3 that needs to be bronzed to obtain the coating layer 31;

[0101] C. Coating bronzing: the combined plate prepared in step A is loaded on the machine, and the coated layer 31 prepared in step B is pressed and bronzed to obtain an electroless aluminum bronzing product.

[0102] as attached Figure 1-2 As shown, the middle part of the hot stamping plate 1 is provided with a boss 11, and the graphic information 21 of the laser nickel plate 2 corresponds to the boss 11 of the hot stamping plate 1, and they are aligned and bonded together.

[0103] In the step A, it is sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com