Anticounterfeit fiber carbor-free copy paper and its production method

A technology of anti-counterfeiting fiber and carbon paper, which is applied in the field of papermaking, can solve the problems of ordinary bill carbonless copy paper not being anti-counterfeiting, and achieve significant economic benefits, advanced anti-counterfeiting technology, and good anti-counterfeiting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Anti-counterfeiting fiber carbonless copy paper is made of the following weight ratio raw materials: (unit: kg / ton of paper)

[0065] (1) base paper

[0066]Pulp 600-950 Talc 10-300 Cationic Dispersed Rosin Gum 3-20

[0067] Cationic starch 3-30 Oxidized starch 10-100 Melamine resin 1-10

[0068] Polyacrylamide 0.5-10 Anti-counterfeit fiber 0.1-2;

[0069] (2) Coatings

[0070] ① CF coating

[0071] Kaolin 50-90 Activated clay 5-30 Oxidized starch 5-20

[0072] Hydroxymethylcellulose 0.5-5 Sodium polyacrylate 0.5-3;

[0073] ②CB paint

[0074] Melamine microcapsules 30-80 Special starch spacers 15-50

[0075] Oxidized starch 5-20 Hydroxymethyl cellulose 0.5-5

[0076] Sodium polyacrylate 0.5-3.

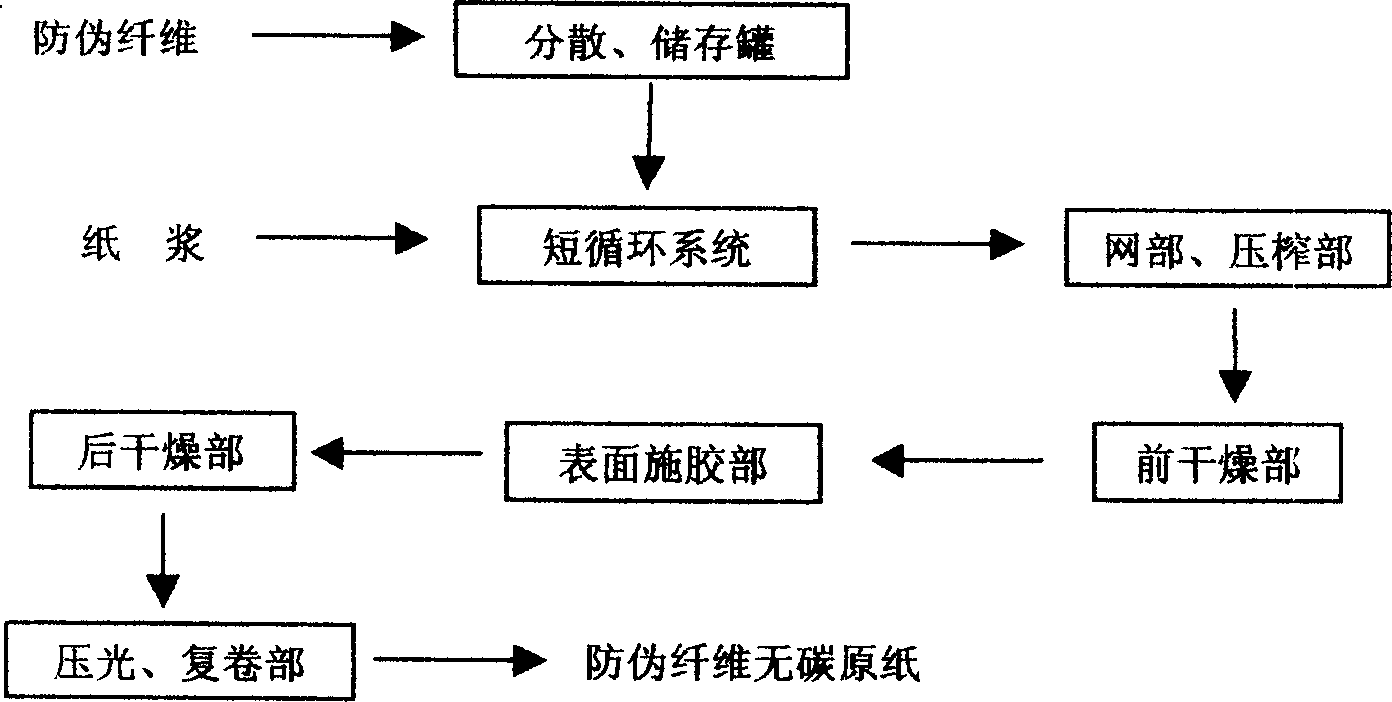

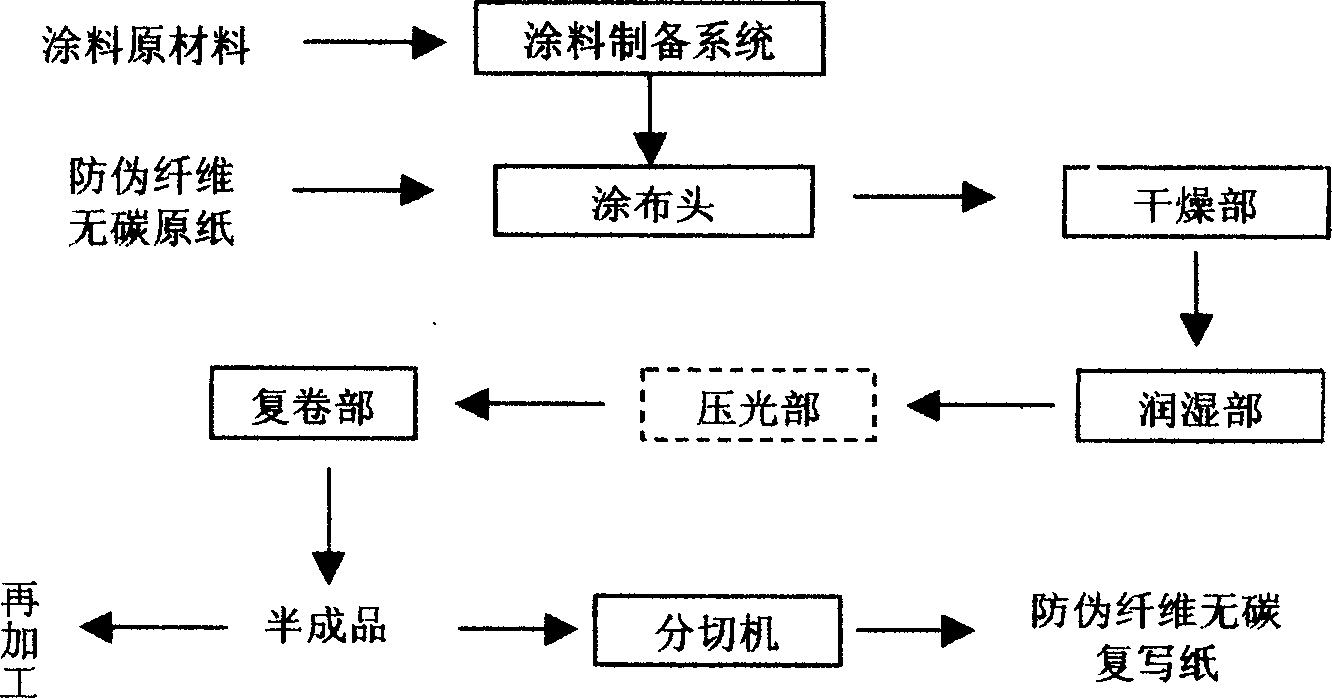

[0077] The production process of anti-counterfeiting fiber carbonless copy paper is as follows:

[0078] (1) According to the needs of users, choose anti-counterfeiting fibers, fluorescent sheets or fluorescent spots. The length of anti-counterfeiting fibers is betwee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com