Manufacturing method of plastic flexible packaging bag with anti-counterfeiting mark

A technology of a flexible packaging bag and a manufacturing method, which is applied to a plastic flexible packaging bag with an anti-counterfeiting mark and its manufacturing field, can solve the problems of easy destruction, alteration, and imitation of a two-dimensional code, so as to achieve good scanning of anti-counterfeiting marks, improve Feasibility and preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

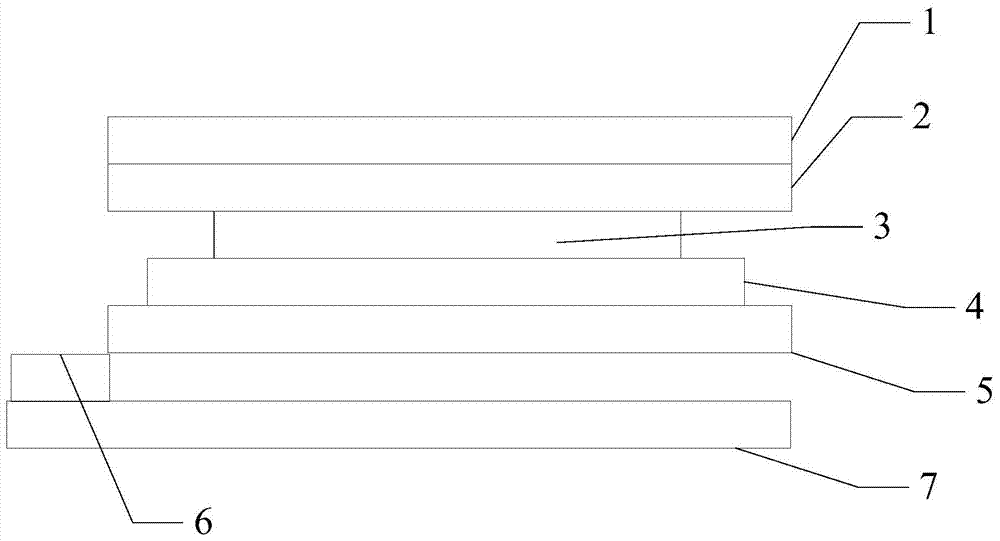

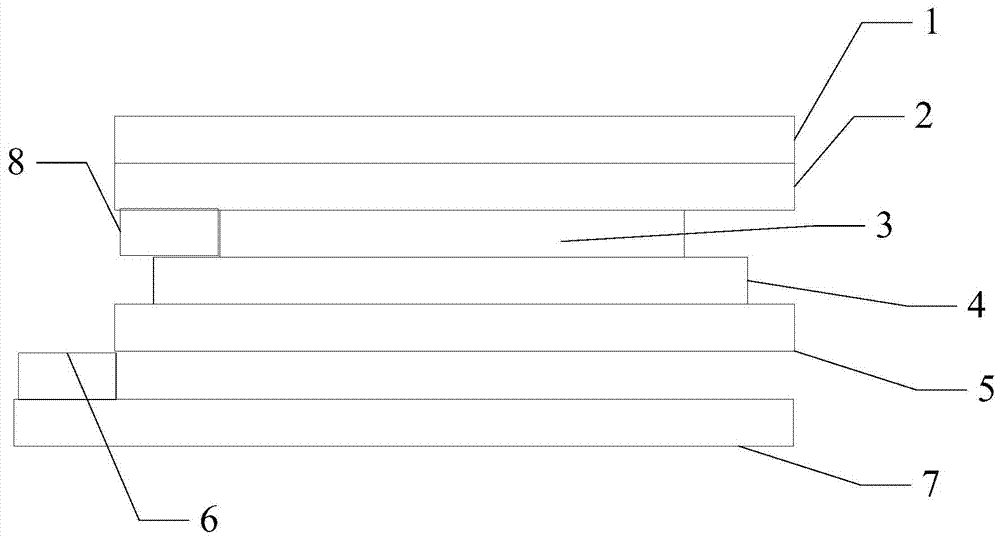

[0041] Such as figure 1 As shown, the plastic flexible packaging bag with anti-counterfeit mark provided by the present invention includes:

[0042] A plastic surface layer 1, for example, the plastic surface layer 1 is a transparent or translucent plastic surface layer;

[0043] Logo adhesion layer 2, which is coated on the lower surface of the plastic surface layer 1, the length and width of the logo adhesion layer 2 are 50mm;

[0044] A variable two-dimensional code marking layer 3, which is spray printed on the lower surface of the marking adhesion layer 2, and part of the printing, that is, printing in the middle of the marking adhesion layer 2, has a length and width of 20 to 30 mm. In a square area, the two-dimensional code in the variable two-dimensional code markin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com