A kind of organic long afterglow material and its preparation method and application

A long afterglow material and captain’s technology, which is applied in the direction of luminescent materials, chemical instruments and methods, can solve the problems of high cost of phosphorescent luminescent materials, short phosphorescence duration, and low phosphorescence intensity, so as to enrich the preparation methods and increase the phosphorescence intensity , the effect of wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

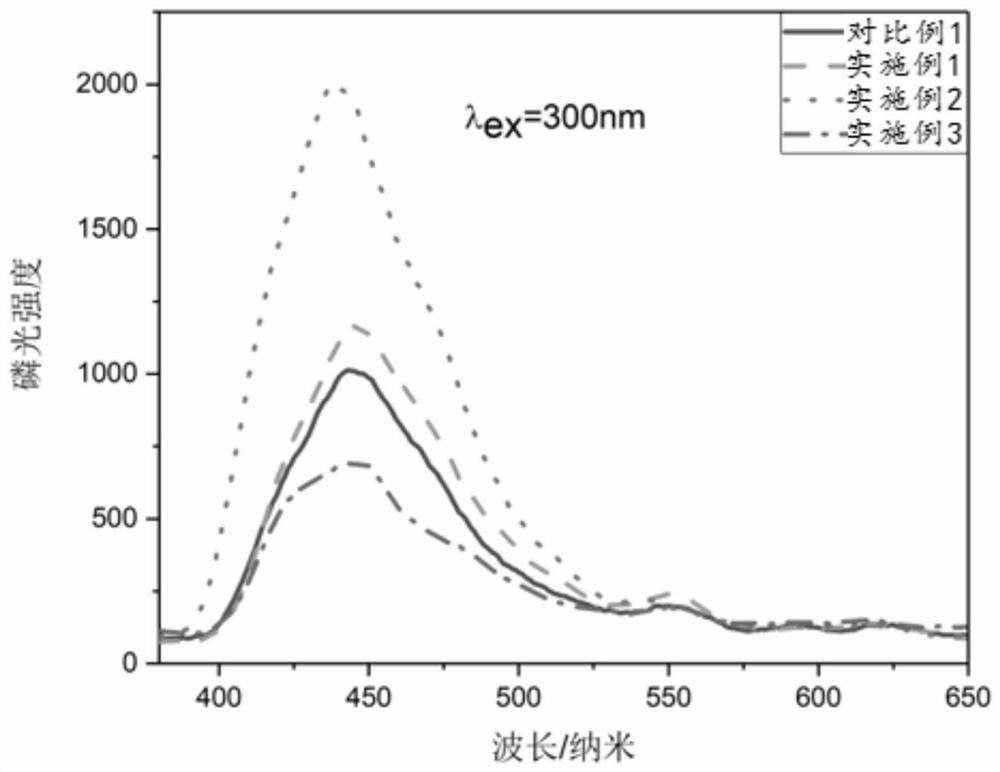

Embodiment 1

[0033] 1) Weigh 0.15g of polyvinyl alcohol (PVA) into a round bottom flask, then add 5ml of deionized water, raise the temperature to 95°C while stirring and keep it for 1.5h to obtain a 30g / L PVA solution.

[0034] 2) Weigh 0.1 mg of diphenylphosphonic anhydride and 4.9 mg of carbazole into the prepared PVA solution, stir ultrasonically at room temperature for 30 minutes, and prepare a mixed solution after mixing evenly, and then use a rubber dropper to uniformly mix the solution Distributed on glass, and baked at 60°C for 4 hours to obtain a transparent and uniform film material.

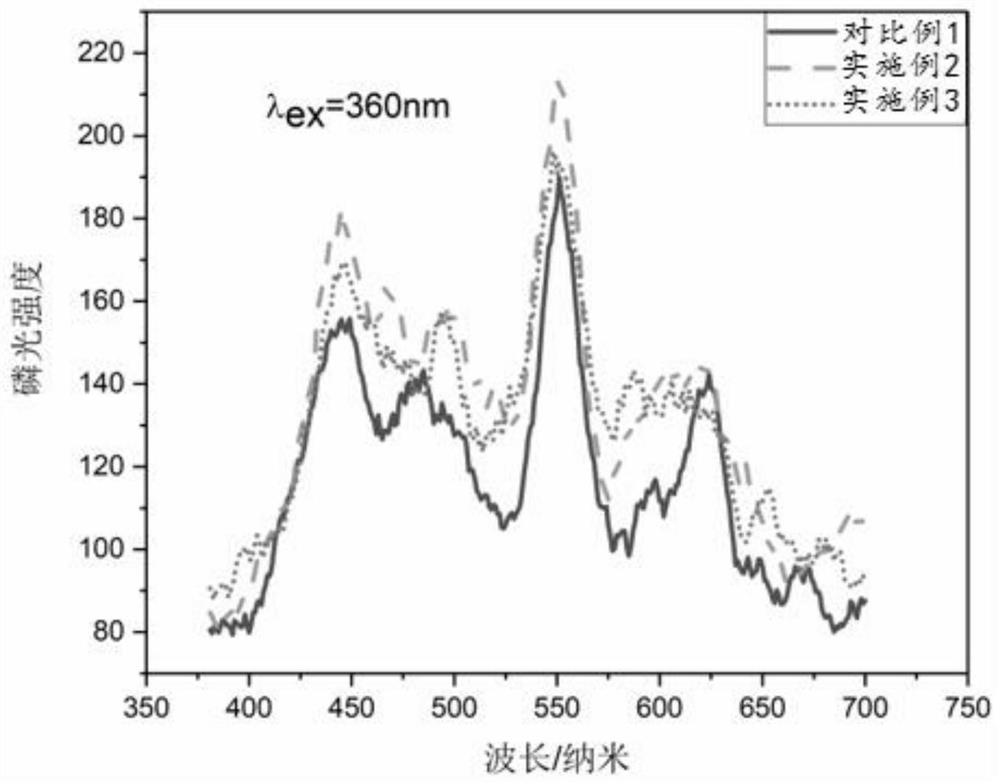

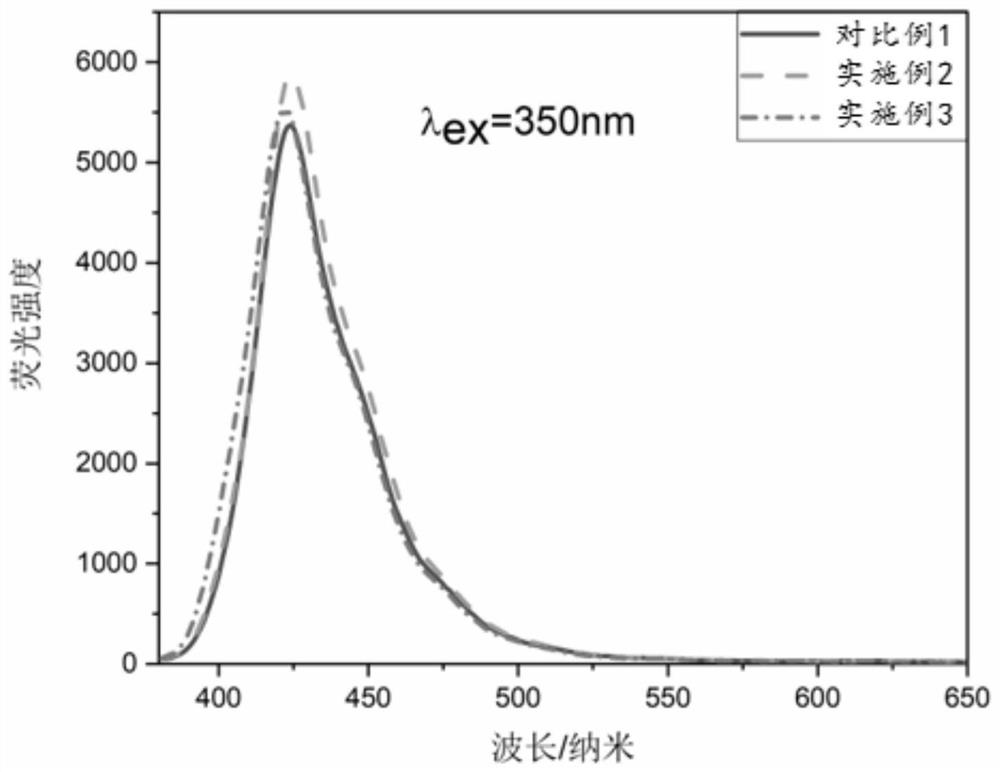

Embodiment 2

[0036] 1) Weigh 0.15g of polyvinyl alcohol (PVA) into a round bottom flask, then add 5ml of deionized water, raise the temperature to 95°C while stirring and keep it for 1h to obtain a 30g / L PVA solution.

[0037] 2) Weigh 0.4 mg of diphenylphosphonic anhydride and 4.6 mg of carbazole into the prepared PVA solution, stir ultrasonically at room temperature for 60 minutes, and prepare a mixed solution after mixing evenly, and then use a rubber dropper to uniformly mix the solution Distributed on glass, and baked at 90°C for 3 hours to obtain a transparent and uniform film material.

Embodiment 3

[0039] 1) Weigh 0.15g of polyvinyl alcohol (PVA) into a round bottom flask, then add 5ml of deionized water, raise the temperature to 95°C while stirring and keep it for 1.5h to obtain a 30g / L PVA solution.

[0040] 2) Weigh 0.6 mg of diphenylphosphonic anhydride and 4.4 mg of carbazole into the prepared PVA solution, stir ultrasonically at room temperature for 90 minutes, and prepare a mixed solution after mixing evenly, and then use a rubber dropper to uniformly mix the solution Distributed on glass, and baked at 100°C for 3 hours to obtain a transparent and uniform film material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com