Cooling sun-protective clothes

A technology for sun protection clothing and clothing, applied in the field of antipyretic sun protection clothing, which can solve the problems of rubber non-absorbent, airtight, and not resistant to long-term heavy pressure, and achieve good anti-counterfeiting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

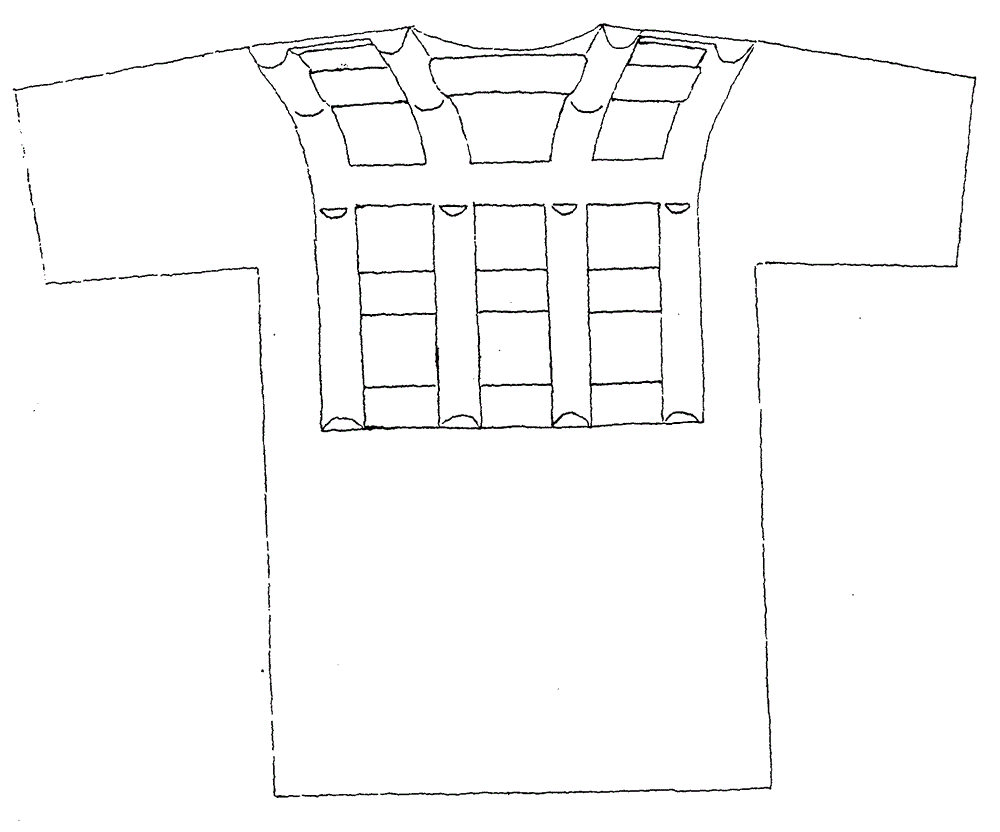

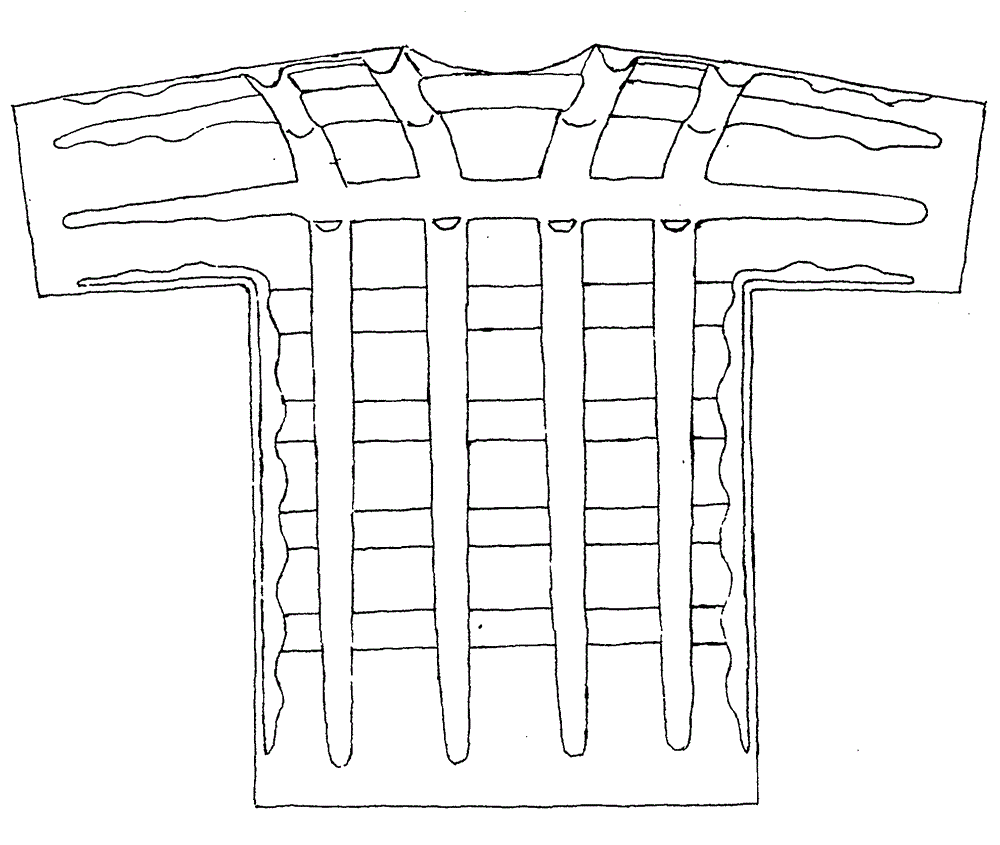

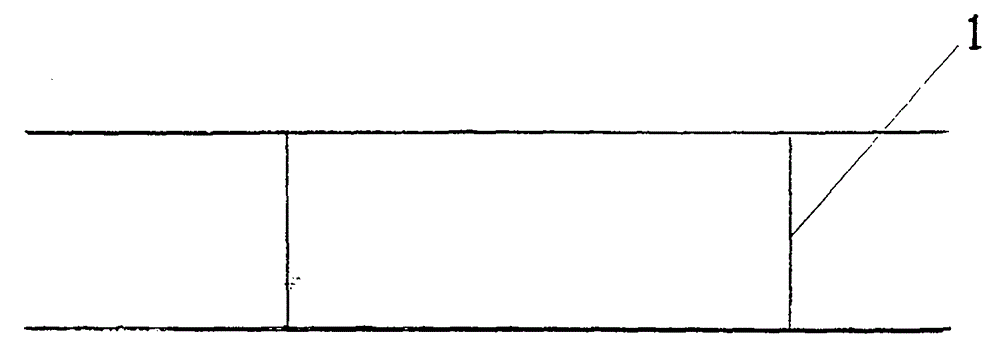

[0010] The shape of this garment is the same as that of generation 1 (such as figure 1 , Figure 4 )2 generations (such as figure 2 , Figure 4 ) is the same as the sun protection shirt. The thickness of the outer rubber layer is 0.2 mm, and a layer of textiles suitable for direct contact with the human body is covered on the inner side of the whole garment. The textile layer is in full and close contact with the outer rubber layer, but does not adhere. The inner garment ribs are hollow. There is a diaphragm inside the hollow clothes tendon, such as image 3 . The surface of the coat has a pattern engraved directly by laser.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com