Volume hologram transfer foil, volume hologram laminate, and production method thereof

A volume hologram and transfer foil technology, which is applied in the process, decorative arts, and instruments for producing decorative surface effects, can solve problems such as insufficient anti-counterfeiting means for holograms, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

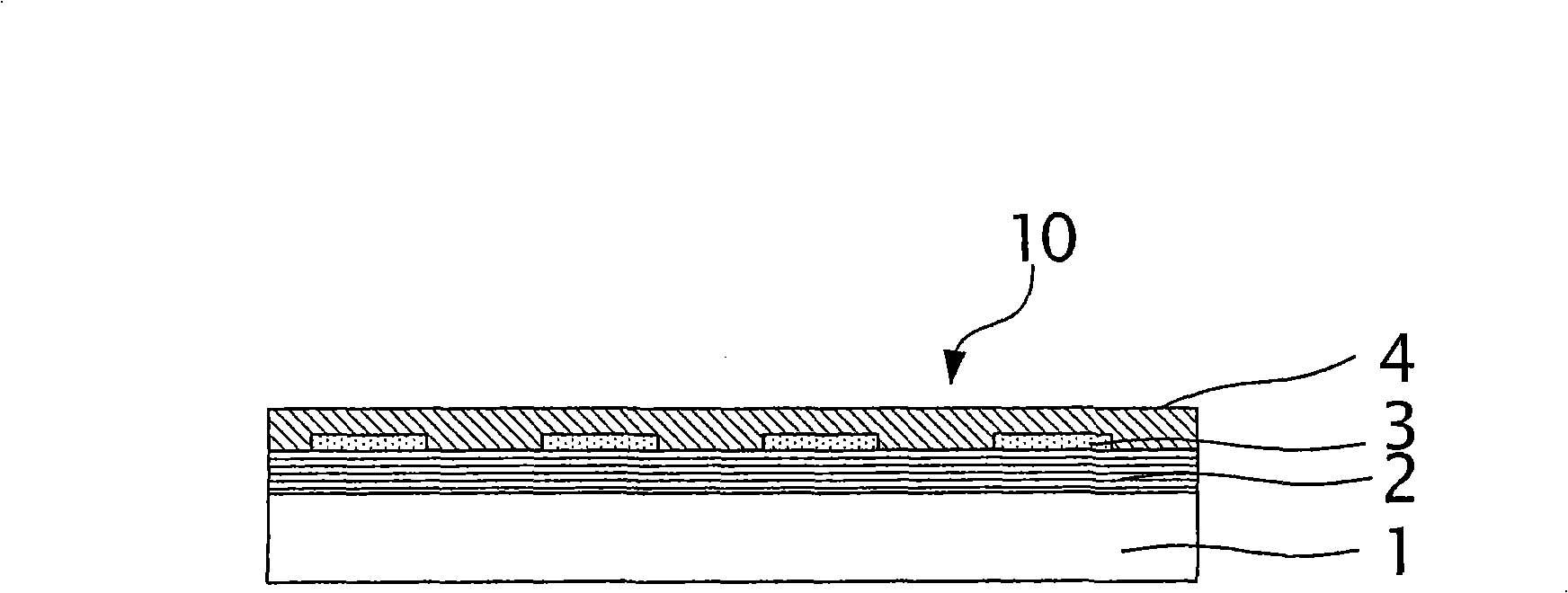

[0355] (1st laminate)

[0356] A PET film (trade name Lumira-T60 (50 μm): manufactured by Toray Co., Ltd.) was prepared as the first film, and a volume hologram recording material having the following composition was coated by gravure printing as a hologram forming material. With a dry film thickness of 7 μm, a surface-release-treated PET film (trade name SP-PET (50 μm), manufactured by Toisero Co., Ltd.) was laminated on the coated surface to prepare a first laminate.

[0357]

[0358] ・Binder resin (polymethyl methacrylate resin (molecular weight: 200,000))

[0359] 50 parts by weight

[0360] 3,9-Diethyl-3'-carboxymethyl-2,2'-thiocarbocyanine iodide salt

[0361] 0.5 parts by weight

[0362] 6 parts by weight of diphenyliodonium hexafluoroantimonate

[0363] 2,2-bis(4-(acryloyldiethoxy)phenyl)propane

[0364] 80 parts by weight

[0365] 80 parts by weigh...

Embodiment 2

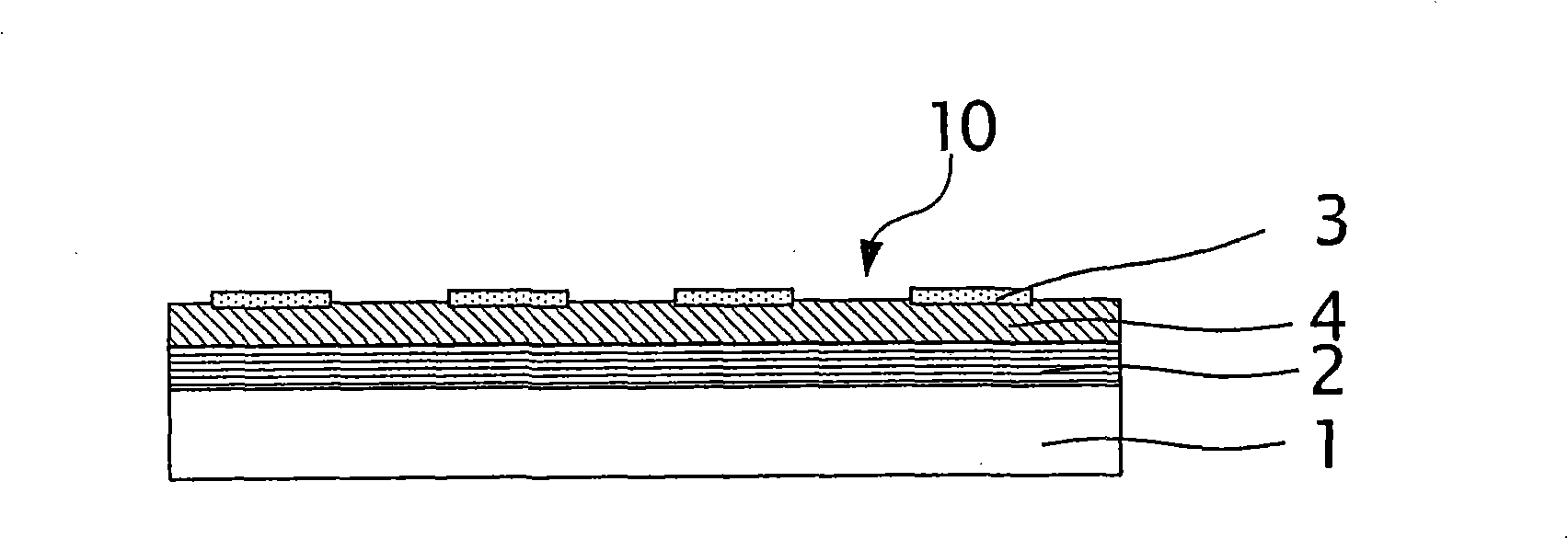

[0386] A volume hologram transfer foil was produced by the same method as in Example 1 except that the following steps were performed to form an image forming layer.

[0387] (Formation of image forming layer)

[0388] The first film of the laminate of the above-mentioned first film / hologram / releasable protective layer / second film is peeled off, and UV PAL BL ink manufactured by Teikoku Ink Manufacturing Co., Ltd. is printed on the volume hologram layer so that the dry film thickness becomes 5 μm , at 80W / cm 2 In metal halide lamps, at about 250mJ / cm 2 UV irradiation is carried out.

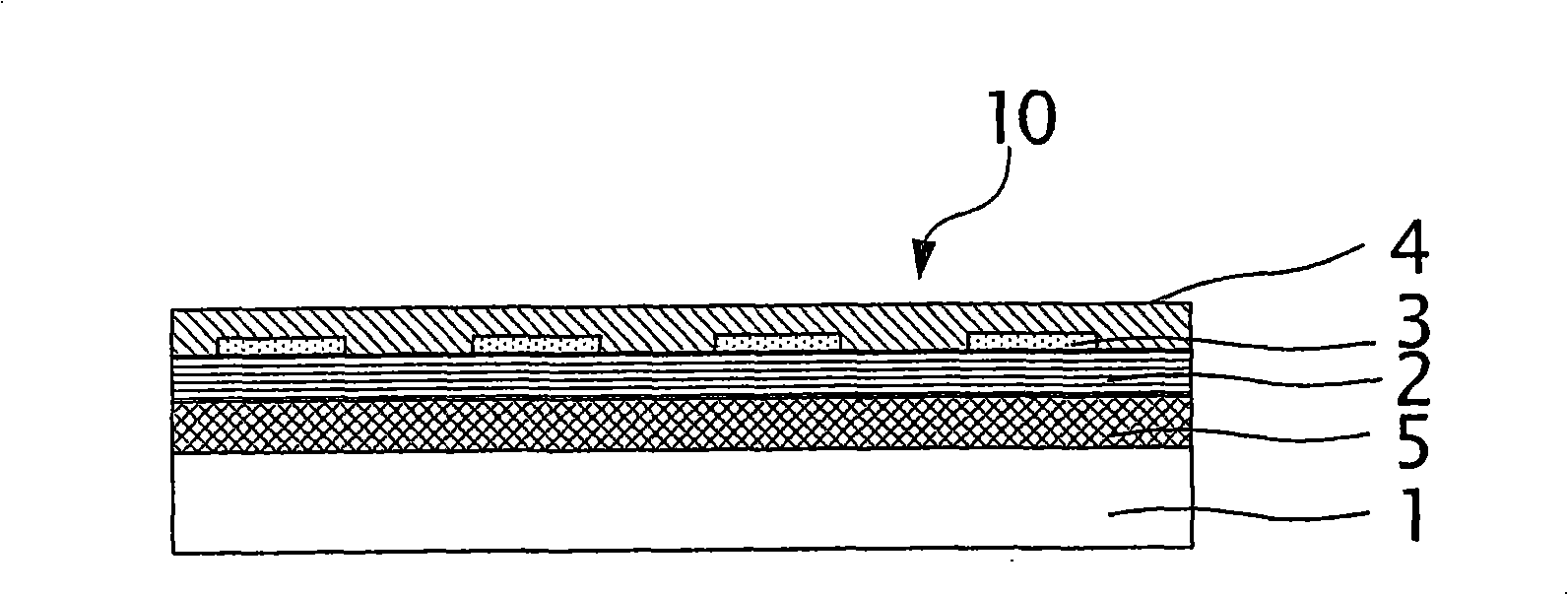

Embodiment 3

[0390] A volume hologram transfer foil was produced by the same method as in Example 1 except that the following steps were performed to form an image forming layer.

[0391] (Formation of image forming layer)

[0392] Peel off the first film of the above-mentioned first film / hologram / peelable protective layer / second film laminate, and print ACT(N) polarized pearl ink on the volume hologram layer by screen printing to make the dry film thickness becomes 5 μm. After natural drying at 20° C. for 10 minutes, ACT(N) 710 ink was printed by screen printing so that the dry film thickness would be 5 μm. Next, natural drying was performed at 20° C. for 10 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com