Method for setting marking pattern on surface of pipe, marking device and pipe

A technology of patterns and pipes, applied in printing, rotary printing machines, printing machines, etc., can solve the problems of counterfeit pipes, increased printing man-hours, and lack of marked patterns, etc., to achieve the effect of improving efficiency and fast printing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

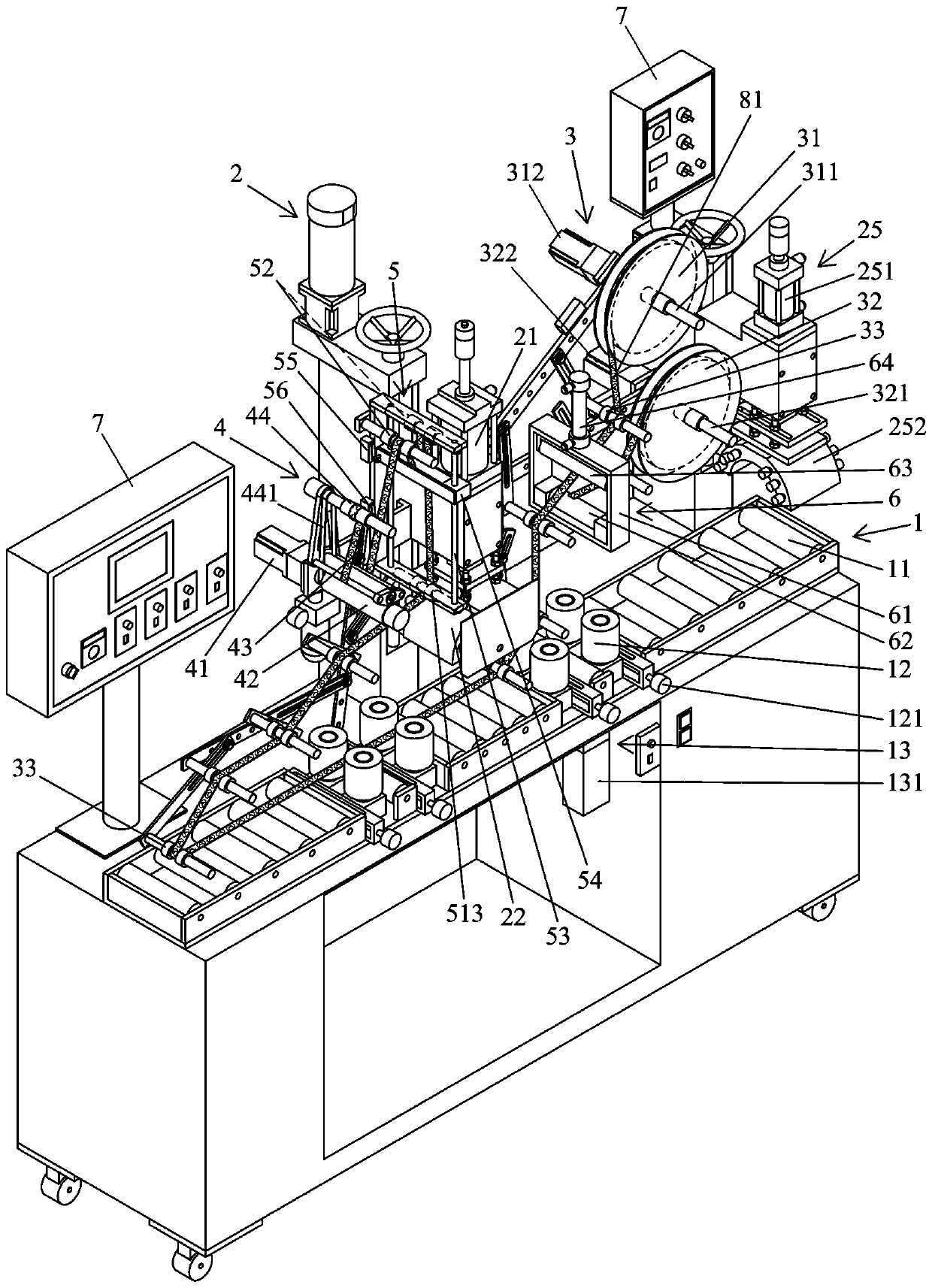

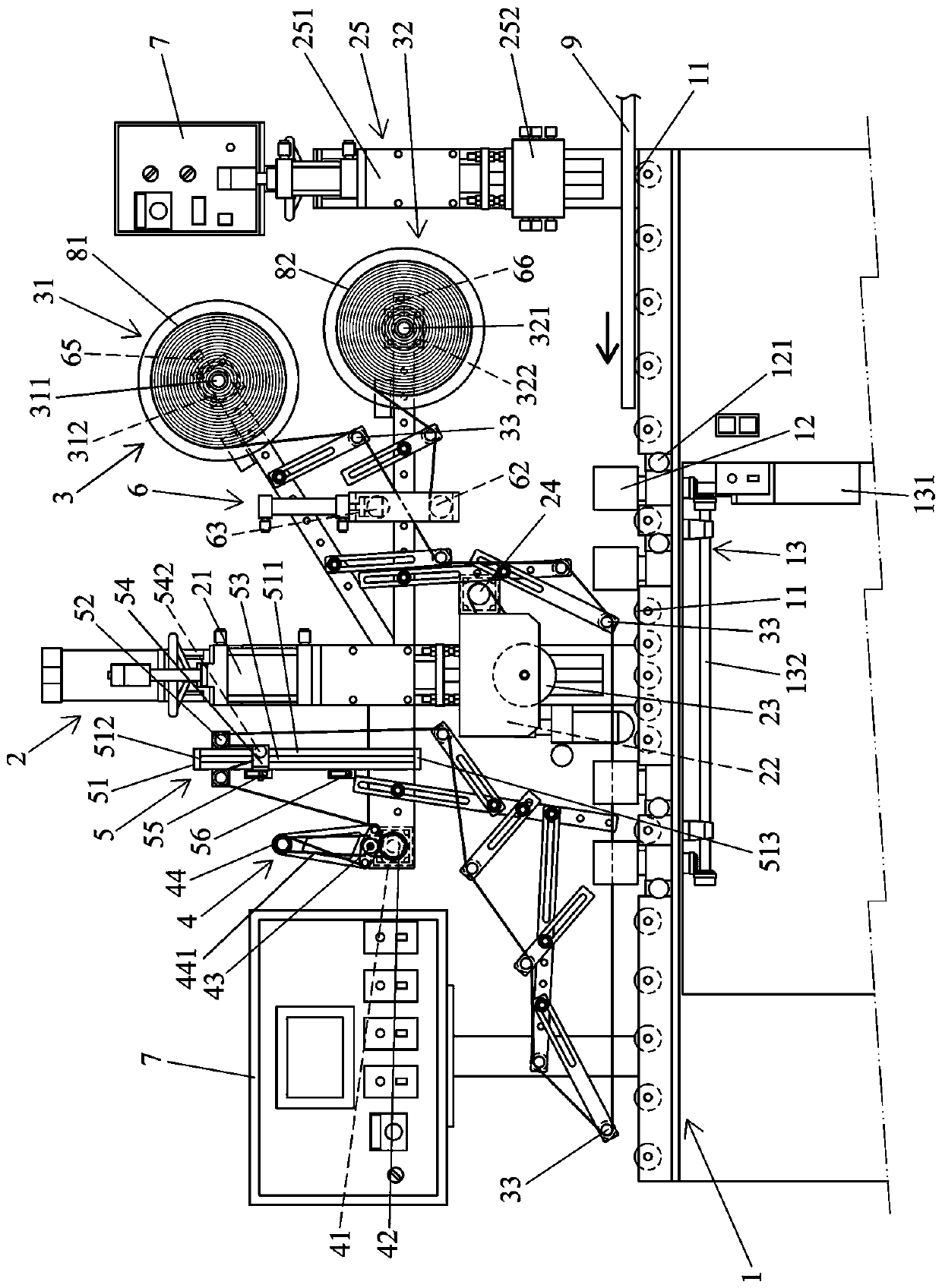

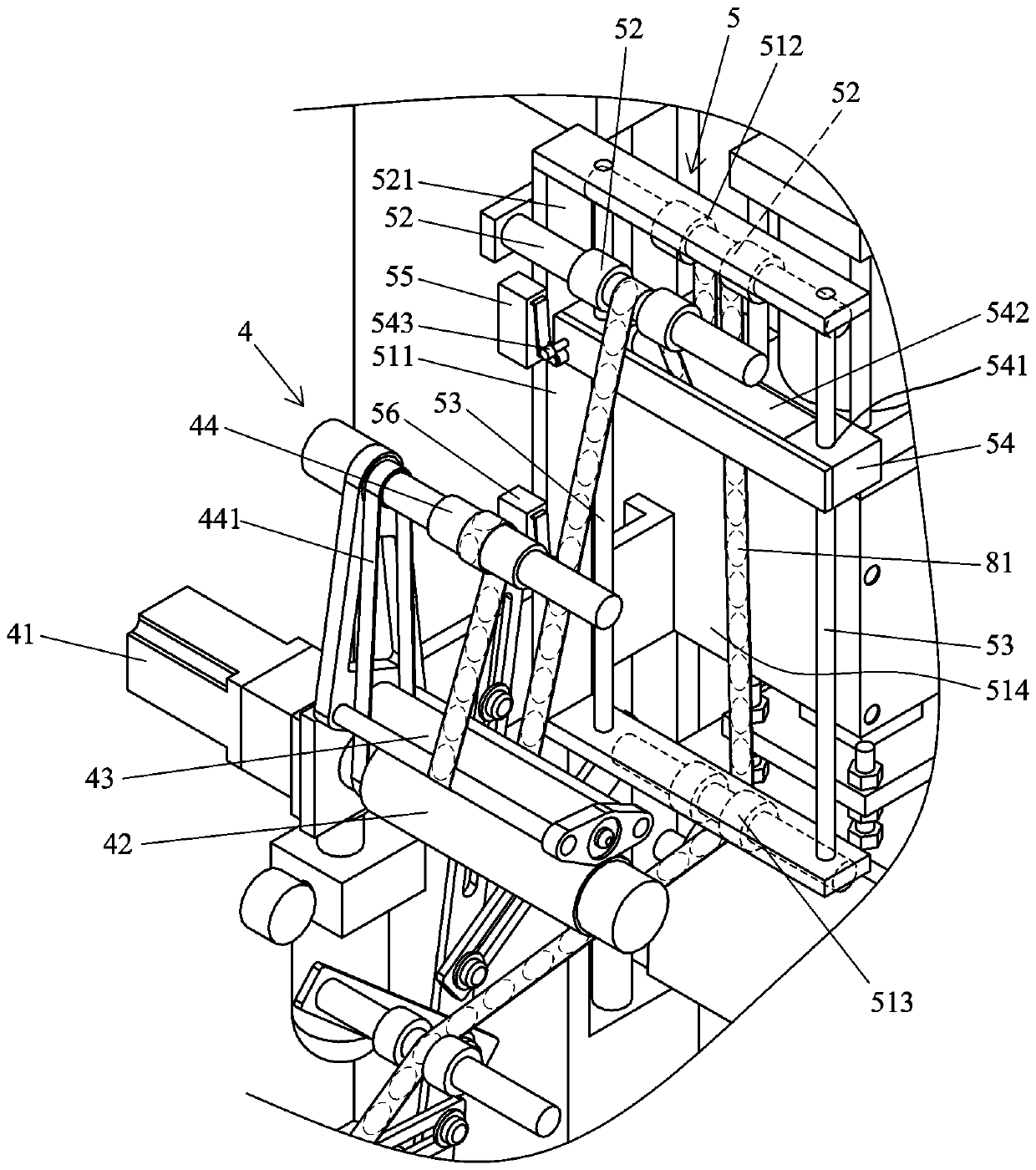

[0062] In order to achieve the above-mentioned purpose and effect, and to further understand the technical solution of the present invention, the preferred embodiments are enumerated below, and in conjunction with the accompanying drawings, the detailed description is as follows:

[0063] The method for setting the marking pattern on the surface of the pipe of the present invention comprises the following steps:

[0064] S1. Install a marking device, which can be heated and embossed;

[0065] S2. Set up a long transfer belt with continuous marking patterns, and the edges of each marking pattern can be connected or the interval is less than 50 cm;

[0066] S3, placing the transfer belt and the pipe at the position of the marking device;

[0067] S4. Make the transfer belt stick to the outer surface of the pipe, and transfer the continuous marking pattern on the transfer belt to the outer surface of the pipe through heating and embossing, and make the continuous marking pattern o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com