Pattern processing method for polyurethane foam materials

A technology of foaming materials and processing methods, which is applied in the processing field of polyurethane foaming materials, can solve the problems of difficult processing, beautiful appearance of polyurethane foaming materials, anti-counterfeiting effects, different colors, etc., and achieve low processing cost, good anti-counterfeiting function, The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

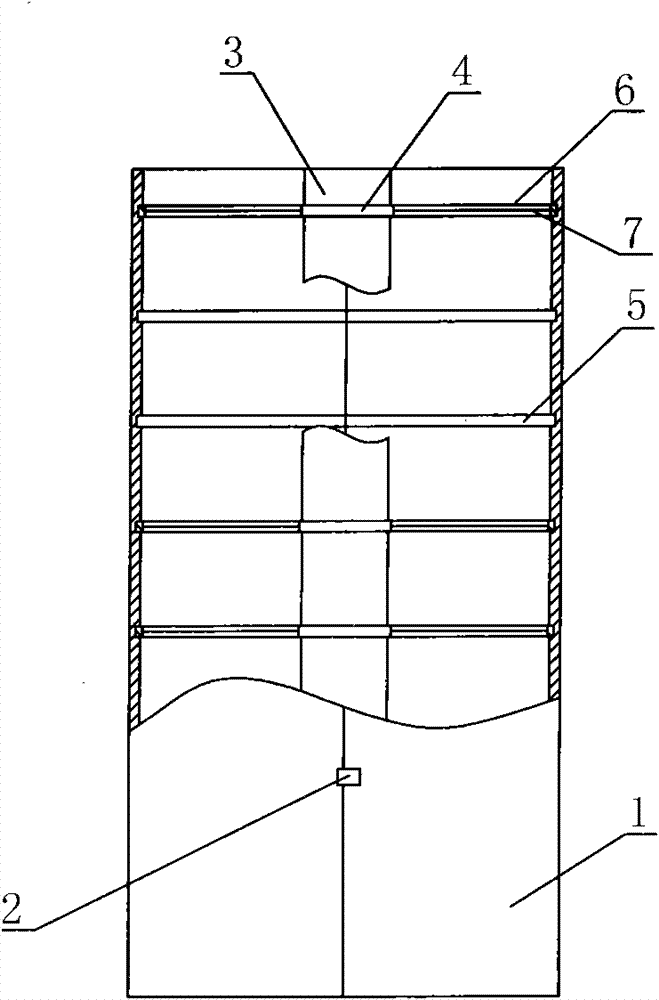

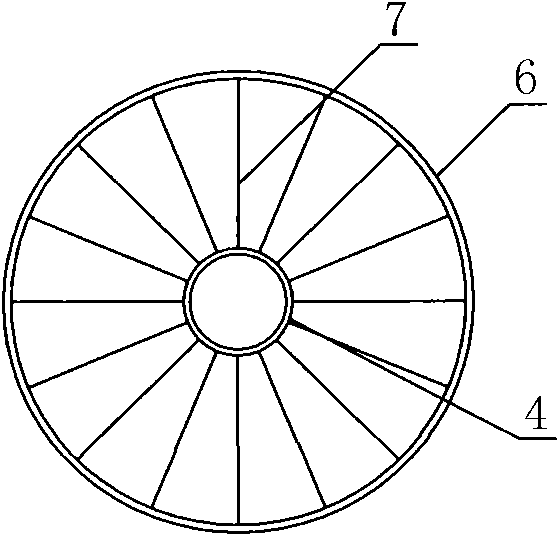

[0014] Example 1: The pattern processing frame includes an outer cylinder frame 1 and an inner cylinder frame 3. The outer cylinder frame 1 is composed of two semicircular cylinders. One side of the two semicircular cylinders is connected by a hinge, and the other side passes through The buckles 2 are buckled together to form a circular cylinder, and the inner wall of the outer cylinder frame 1 is provided with a plurality of mutually parallel clamping grooves 5; the inner cylinder frame 3 is arranged in the central position inside the outer cylinder frame 1.

[0015] The color wire rack includes an inner wire hoop 4 and an outer wire hoop 6. The outer wire hoop 6 is matched with the slot 5 on the inner wall of the outer tube frame 1, the inner wire hoop 4 is set in the center position inside the outer wire hoop 6, and the inner wire hoop 4 is matched with the inner tube frame 3 , A plurality of nylon colored threads 7 are evenly arranged radially between the inner wire hoop 4 and...

Embodiment 2

[0017] Embodiment 2: The pattern processing frame includes an outer cylinder frame 1 and an inner cylinder frame 3. The outer cylinder frame 1 is composed of two semicircular cylinders, one side of the two semicircular cylinders is connected by a hinge, and the other side passes through The buckles 2 are buckled together to form a circular cylinder, and the inner wall of the outer cylinder frame 1 is provided with a plurality of mutually parallel clamping grooves 5; the inner cylinder frame 3 is arranged in the central position inside the outer cylinder frame 1.

[0018] The color wire rack includes an inner wire hoop 4 and an outer wire hoop 6. The outer wire hoop 6 is matched with the slot 5 on the inner wall of the outer tube frame 1, the inner wire hoop 4 is set in the center position inside the outer wire hoop 6, and the inner wire hoop 4 is matched with the inner tube frame 3 , A plurality of cotton colored threads 7 are evenly arranged radially between the inner wire hoop 4...

Embodiment 3

[0020] Example 3: The pattern processing frame includes an outer cylinder frame 1 and an inner cylinder frame 3. The outer cylinder frame 1 is composed of two semicircular cylinders. One side of the two semicircular cylinders is connected by a hinge, and the other side passes through The buckles 2 are buckled together to form a circular cylinder, and the inner wall of the outer cylinder frame 1 is provided with a plurality of mutually parallel clamping grooves 5; the inner cylinder frame 3 is arranged in the central position inside the outer cylinder frame 1.

[0021] The color wire rack includes an inner wire hoop 4 and an outer wire hoop 6. The outer wire hoop 6 is matched with the slot 5 on the inner wall of the outer tube frame 1, the inner wire hoop 4 is set in the center position inside the outer wire hoop 6, and the inner wire hoop 4 is matched with the inner tube frame 3 , A plurality of polyurethane colored lines 7 are evenly arranged radially between the inner wire hoop ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com