Method for preparing firm flexible printed board

A technology of a rigid-flex printed board and a manufacturing method, which is used in the manufacture of multi-layer circuits and the formation of electrical connection of printed components, etc., can solve the problems of difficult gold plating, poor operability, and poor reliability, and achieves strong repeatability and no Individual differences, the effect of realizing mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the specific embodiments and drawings. This specific embodiment is described for the second type of rigid-flex printed boards of four layers, but the method of the present invention can be applied to other types of rigid-flex printed boards equally, and for other layers (such as 6, 8 layers ) Rigid-flex printed boards are also applicable.

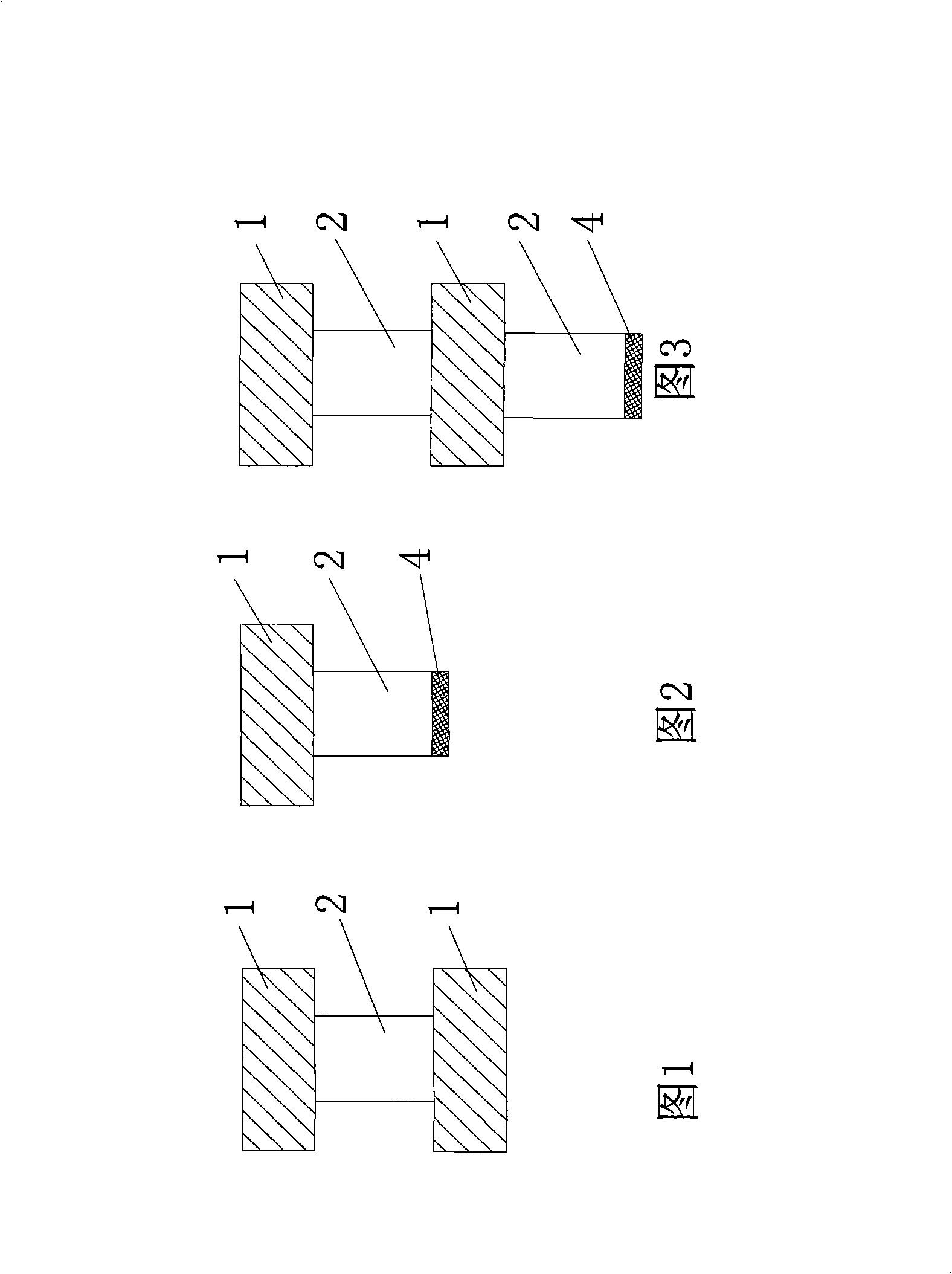

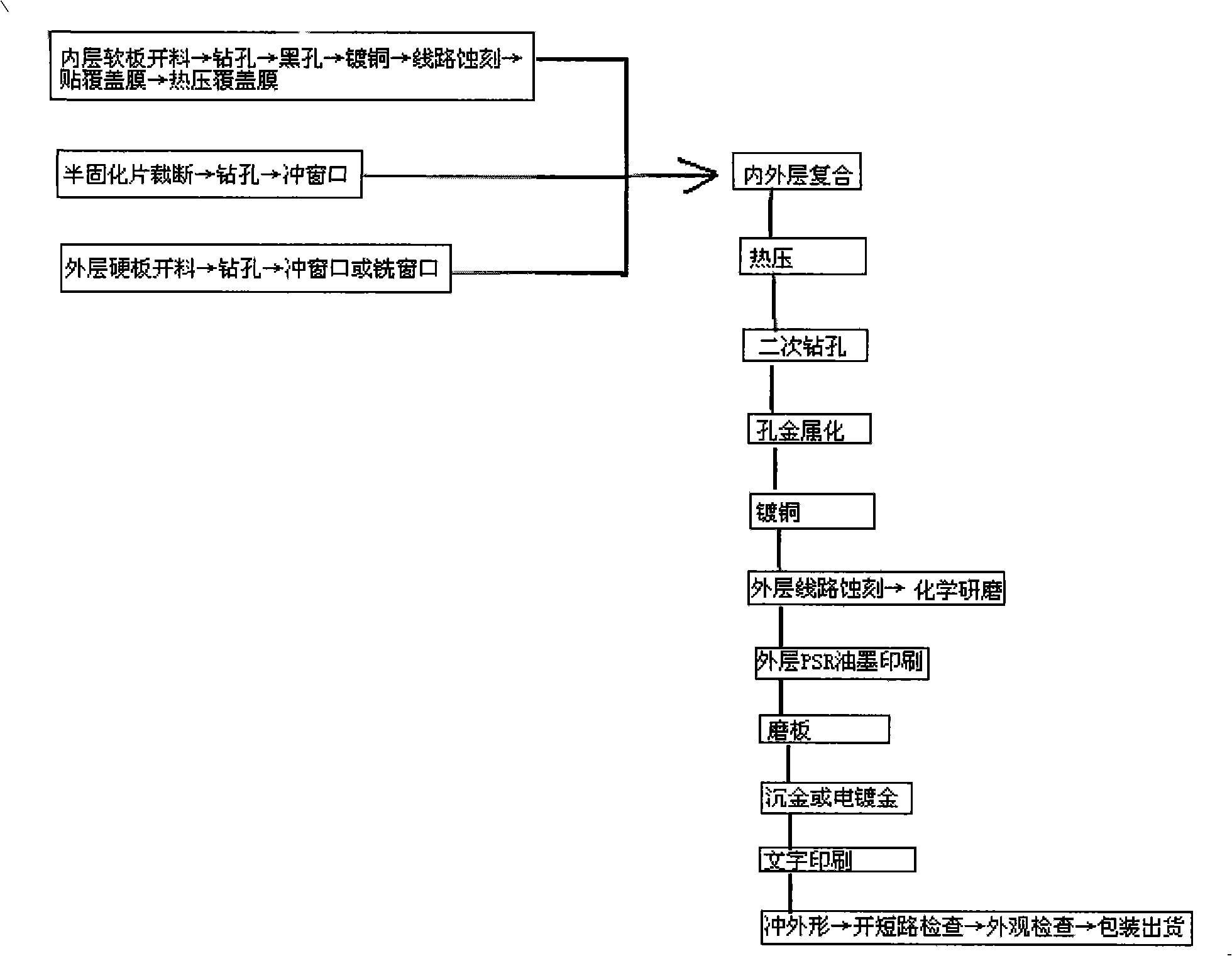

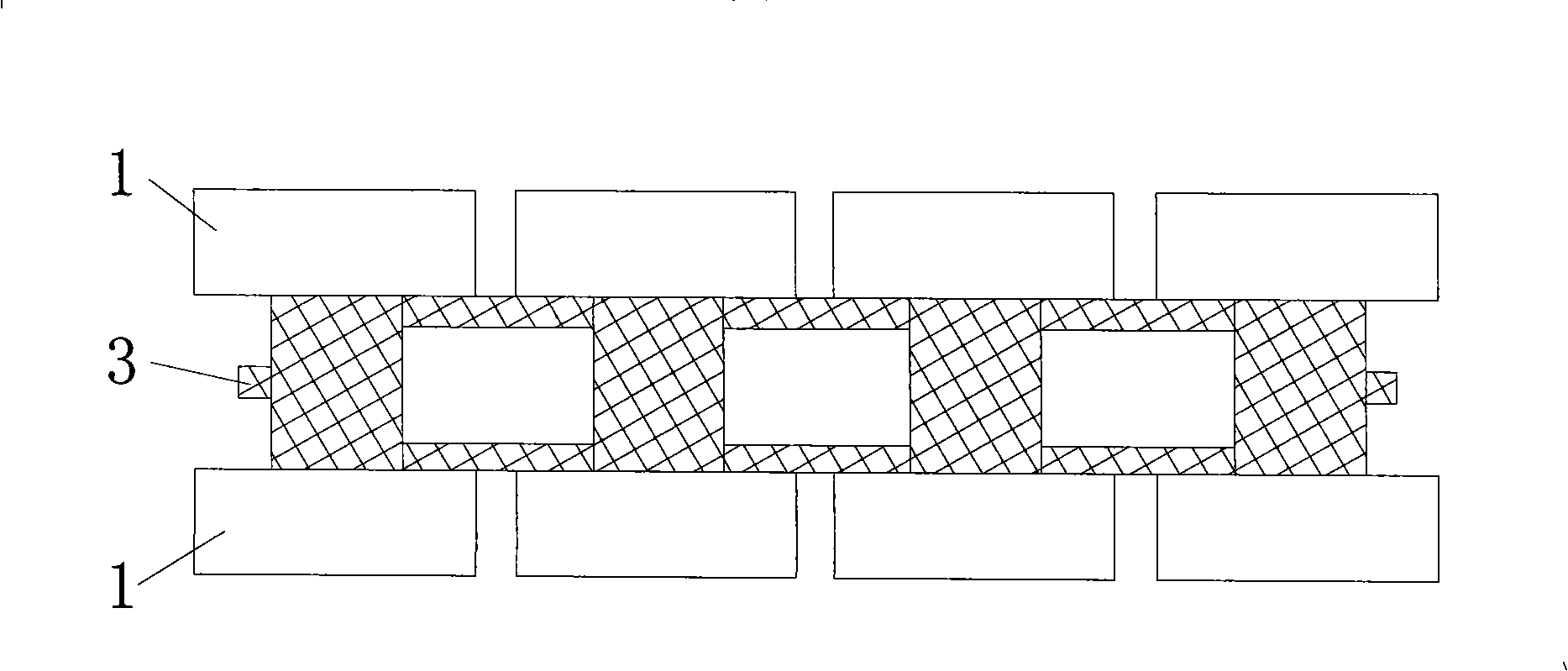

[0034] Such as Figure 7 As shown, a four-layer rigid-flex printed board of the second type includes an outer layer (layer 1 and layer 4) composed of a rigid circuit board 1, and an inner layer composed of a flexible circuit board 2 (layers 2 and 3 ), the line pad 4 on the flexible board (ie the gold finger pad). The circuit board needs to be printed with a peelable mask layer 3 during the manufacturing process of the present invention, and the peelable mask layer 3 will be torn off in the subsequent process. Such as Image 6 with Figure 8 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com