Gold-coated-sliver base bonding silk thread and manufacture method thereof

A manufacturing method, silver-based gold-coated technology, applied in manufacturing tools, semiconductor/solid-state device manufacturing, furnace types, etc., can solve the problems of resource scarcity and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

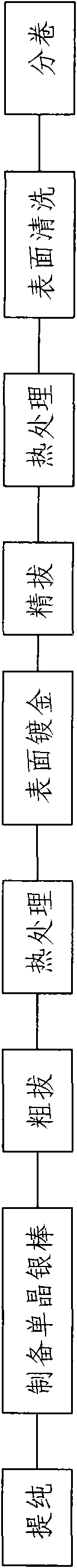

Method used

Image

Examples

Embodiment 1

[0023] ①Purification: Dilute the silver nitrate solution with high-purity water at a ratio of 1:4 to prepare an electrolyte; use the national standard No. 1 silver block as the anode to immerse in the electrolyte, and ensure that 95% of the volume ratio of the silver block is immersed in the electrolyte; Use high-purity silver foil as the cathode to immerse in the electrolyte, and also ensure that 95% of the volume ratio of high-purity silver foil is immersed in the electrolyte; input 7-9V, 2.5-3.5A DC between the anode and cathode to maintain fresh electrolyte The temperature of the electrolyte does not exceed 60°C; when the cathode accumulates high-purity silver with a purity greater than 99.9995%, replace the high-purity silver foil in time, then clean and dry it for later use.

[0024] ②Preparation of single crystal silver rods: In a continuous casting room for horizontal continuous casting of metal single crystals protected by nitrogen, add purified high-purity silver with...

Embodiment 2

[0033] Step 1. to step 4. are the same as in Embodiment 1.

[0034] ⑤Gold plating on the surface: Apply conventional electroplating equipment and technology to the annealed Silver wire electroplating pure gold anti-oxidation protective layer, the purity of gold used for electroplating is required to be greater than 99.999%; the current density is 4-4.5A / dm 2 , the silver wire speed is 3.5-4m / min, and the thickness of the coating is controlled at 3μm; the silver wire products after gold plating, according to the density of pure silver, is 10.5g / cm 3 , The density of pure gold is 19.3g / cm 3 In conversion, the weight percentage of gold is 10.0%, and the rest is silver.

[0035]⑥Precise drawing: Using conventional precision drawing equipment and technology, the aforementioned pure gold anti-oxidation protective layer is electroplated Silver thread, through multi-pass process, precision drawn into silver-based gold-clad bonding wire; for this The silver-based gold-clad bon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com