Automotive weatherproof ASA material, and preparation method and application thereof

A technology of ASA resin and weather resistance, applied in the field of preparation of ASA materials, can solve the problems of late ASA and no industrialized production, and achieve the effect of promoting aging resistance, good processability and good weather resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

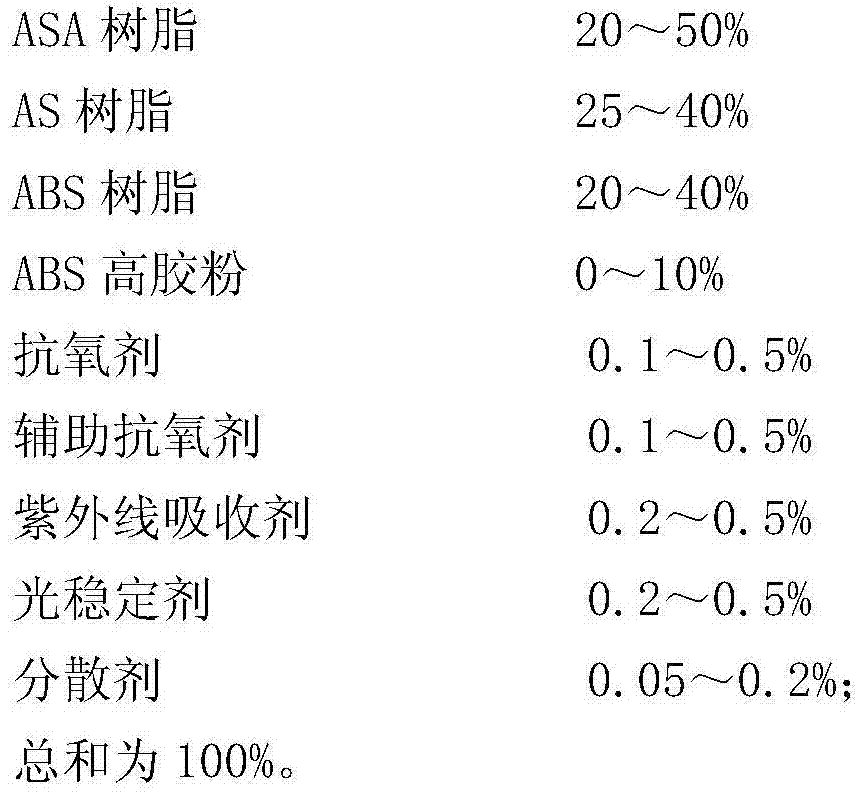

Method used

Image

Examples

Embodiment 1

[0029]

[0030] Put each component into a high-speed mixer and stir for 4 minutes according to the percentage of the quantity. The mixture is extruded, cooled, and pelletized through a co-rotating twin-screw extruder. The screw speed of the extruder is 300r / min. Set temperature (°C)- Zone 200, Zone 2 240, Zone 3 240, Zone 4 240, Zone 5 220, Zone 6 210, Zone 7 190, Zone 8 200, Zone 9 210, Machine Head 240. The feeding speed is 50r / min. The obtained ASA was dried in an oven at 85° C. for 2 hours. The performance test results are shown in Table 1.

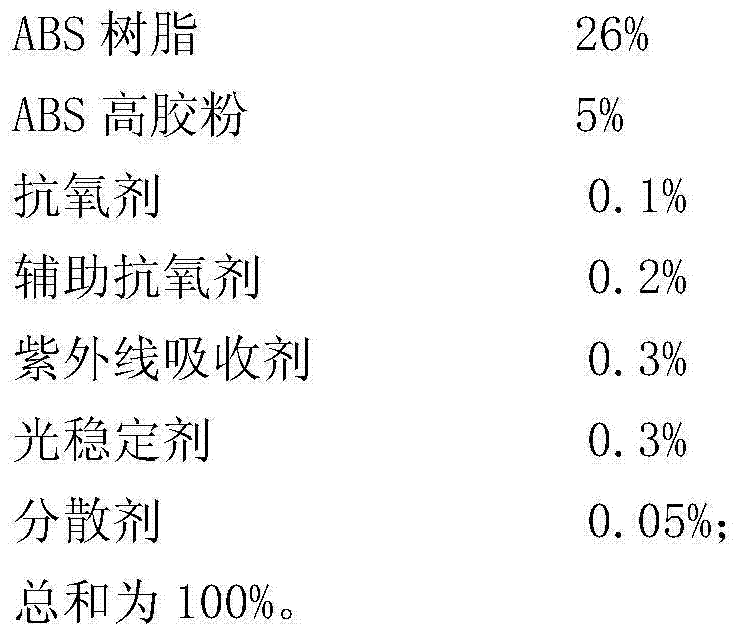

Embodiment 2

[0032]

[0033] Put each component into a high-speed mixer and stir for 4 minutes according to the percentage of the quantity. The mixture is extruded, cooled, and pelletized through a co-rotating twin-screw extruder. The screw speed of the extruder is 300r / min, and the set temperature (°C) Zone 1 200, Zone 2 240, Zone 3 240, Zone 4 240, Zone 5 220, Zone 6 210, Zone 7 190, Zone 8 200, Zone 9 210, Machine Head 240. The feeding speed is 50r / min. The obtained ASA was dried in an oven at 85° C. for 2 hours. The performance test results are shown in Table 1.

Embodiment 3

[0035]

[0036] Put each component into a high-speed mixer and stir for 4 minutes according to the percentage of the quantity. The mixture is extruded, cooled, and pelletized through a co-rotating twin-screw extruder. The screw speed of the extruder is 300r / min, and the set temperature (°C) Zone 1 200, Zone 2 240, Zone 3 240, Zone 4 240, Zone 5 220, Zone 6 210, Zone 7 190, Zone 8 200, Zone 9 210, Machine Head 240. The feeding speed is 50r / min. The obtained ASA was dried in an oven at 85° C. for 2 hours. The performance test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com