Ultrahigh temperature decomposition agent of straws and cattle manure, and preparation and application of decomposition agent

An ultra-high temperature, decomposing agent technology, applied in the field of decomposing agent, can solve the problems of poor compost quality, incomplete decomposition, low fermentation temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

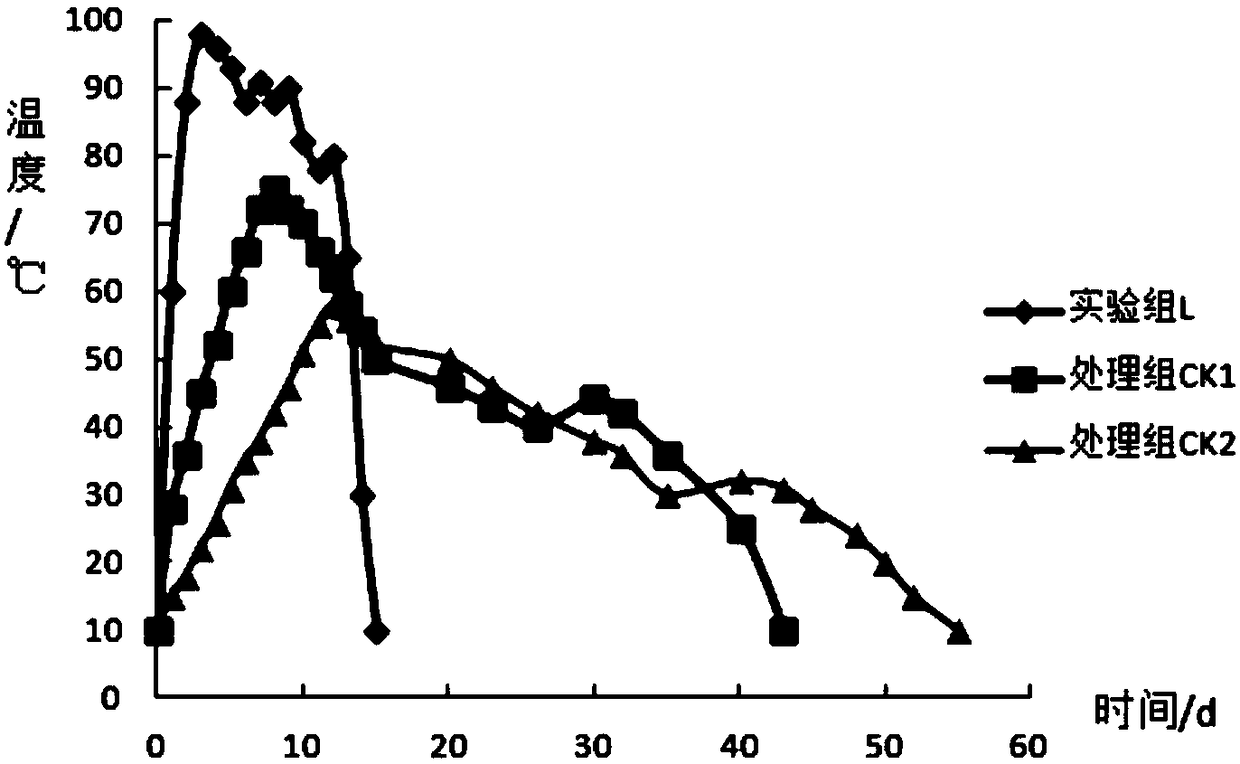

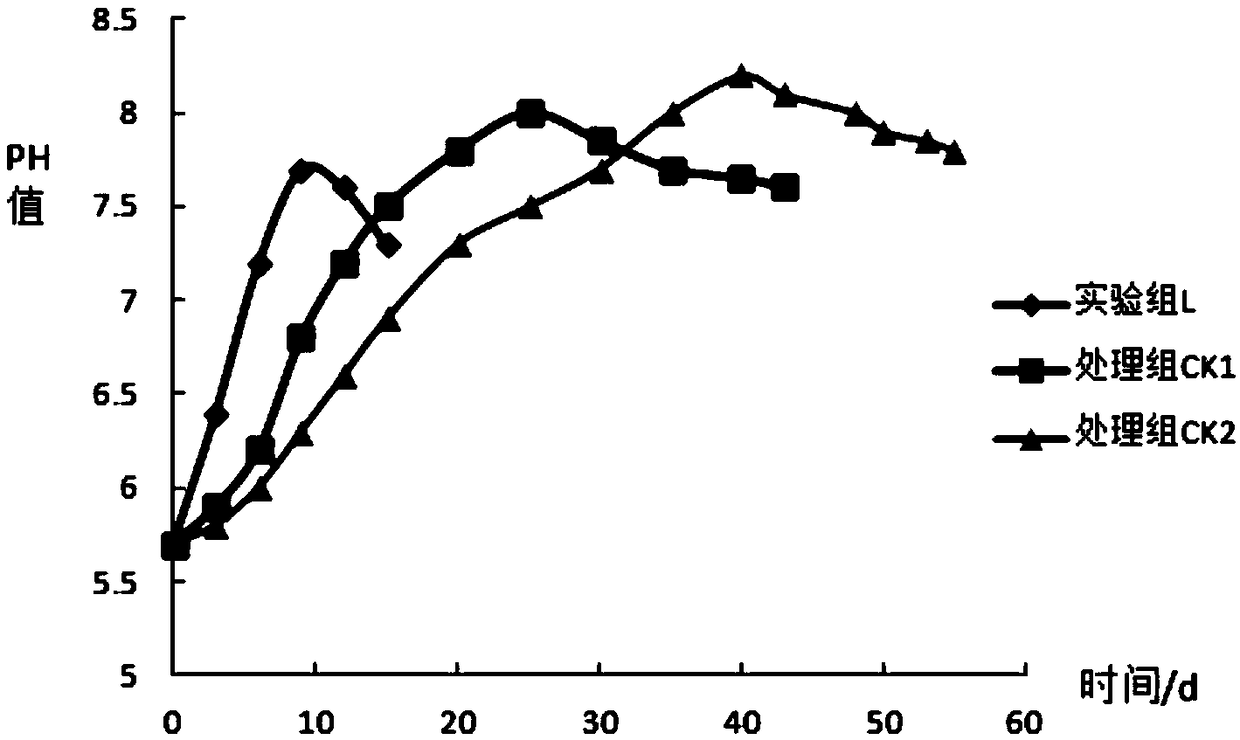

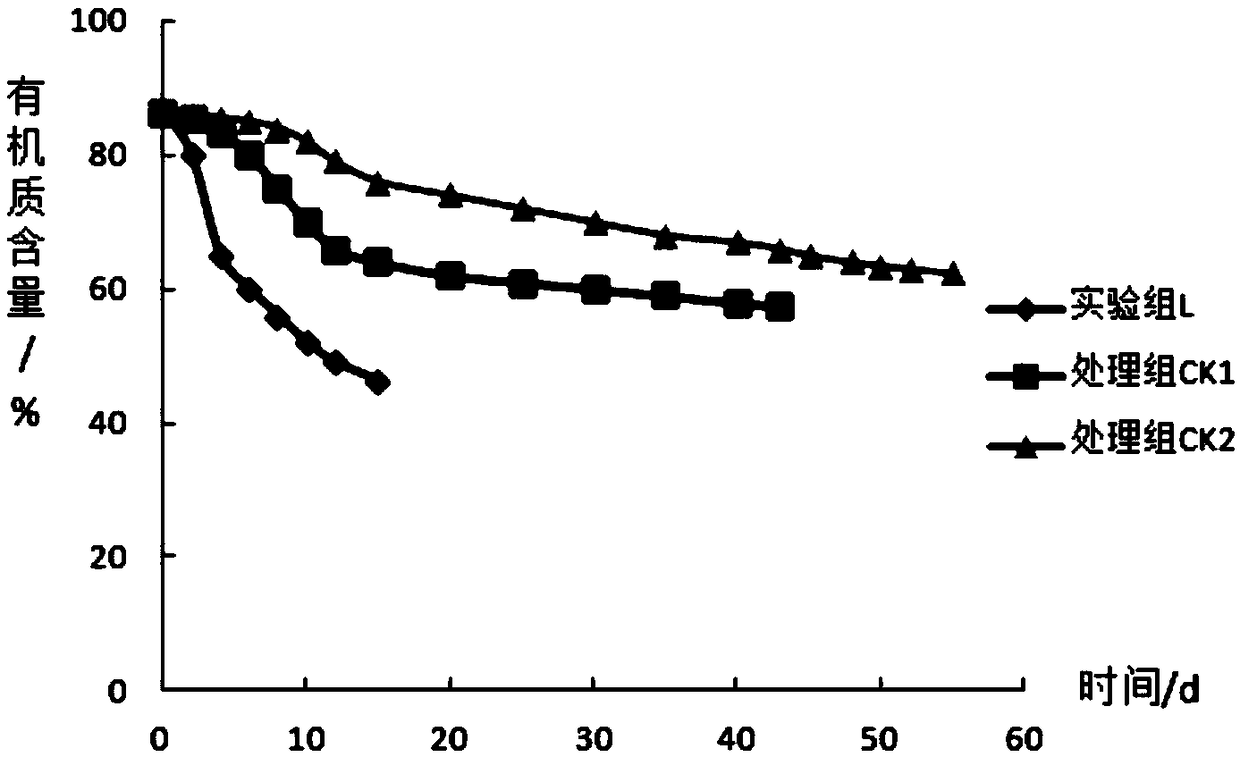

[0079] Embodiment 1 The preparation method of straw and cow dung ultra-high temperature decomposing agent

[0080] (1) Bacterial agent mixing: 6 parts of thermophilic bacterial agent, 4 parts of Bacillus licheniformis bacterial agent, 4 parts of Aspergillus oryzae bacterial agent, 4 parts of Lactobacillus plantarum bacterial agent, 4 parts of Lanxiella sugarcane bacterial agent, cold-resistant Mix 4 parts of the Brevibacterium bacterial agent, and pass through a 40-mesh sieve to obtain a decomposed compound bacterial agent;

[0081] (2) mixing fresh straw and cow dung according to a mass ratio of 5:1 to obtain a mixed pile, the water content of which is 55%-65%;

[0082] (3) Inoculate the decomposed compound bacterial agent into the mixed pile with an inoculum amount of 1‰ by mass ratio, mix and stir, and carry out decomposing treatment. Under the condition that the initial composting temperature is 10°C, compost for 13 days to obtain straw and cow dung Ultra-high temperature...

Embodiment 2

[0100] Example 2 The preparation method of straw and cow dung ultra-high temperature decomposing agent

[0101] (1) Bacterial agent mixing: 3 parts of thermophilic bacterial agent, 2 parts of Bacillus licheniformis bacterial agent, 2 parts of Aspergillus oryzae bacterial agent, 2 parts of Lactobacillus plantarum bacterial agent, 2 parts of Lanxiella sugarcane bacterial agent, cold-resistant Mix 2 parts of the Brevibacterium inoculum and pass through a 30-mesh sieve to obtain a decomposed compound inoculum;

[0102] (2) fresh straw and cow dung are mixed according to the mass ratio of 11:6 to obtain a mixed pile, and the water content of the mixed pile is 60%-65%;

[0103] (3) Inoculate the decomposed compound bacterial agent into the mixed compost with an inoculation amount of 1.5‰ by mass ratio, mix and stir, and carry out decomposing treatment under the condition that the initial composting temperature is 10°C, and compost for 10 days to obtain straw and cow dung Ultra-high...

Embodiment 3

[0112] Example 3 The preparation method of straw and cow dung ultra-high temperature decomposing agent

[0113] (1) Bacterial agent mixing: 8 parts of thermophilic bacterial agent, 5 parts of Bacillus licheniformis bacterial agent, 5 parts of Aspergillus oryzae bacterial agent, 5 parts of Lactobacillus plantarum bacterial agent, 5 parts of Lanxiella sugarcane bacterial agent, cold-resistant Mix 5 parts of Brevibacterium inoculum and pass through a 40-mesh sieve to obtain a decomposed compound inoculum;

[0114] (2) fresh straw and cow dung are mixed according to a mass ratio of 12:5 to obtain a mixed pile, and the water content of the mixed pile is 55%-65%;

[0115] (3) Inoculate the decomposed compound bacterial agent into the mixed compost with an inoculation amount of 1-2‰ by mass ratio, mix and stir, and carry out decomposing treatment under the condition that the initial composting temperature is 11° C., and compost for 12 days to obtain straw And cow dung ultra-high tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com