PVC plastic cement floor and production technology thereof

A technology of plastic floor and production process, applied in the direction of construction, building structure, floor, etc., can solve the problems of poor anti-skid performance and poor wear resistance, and achieve the effect of super mucous membrane performance and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

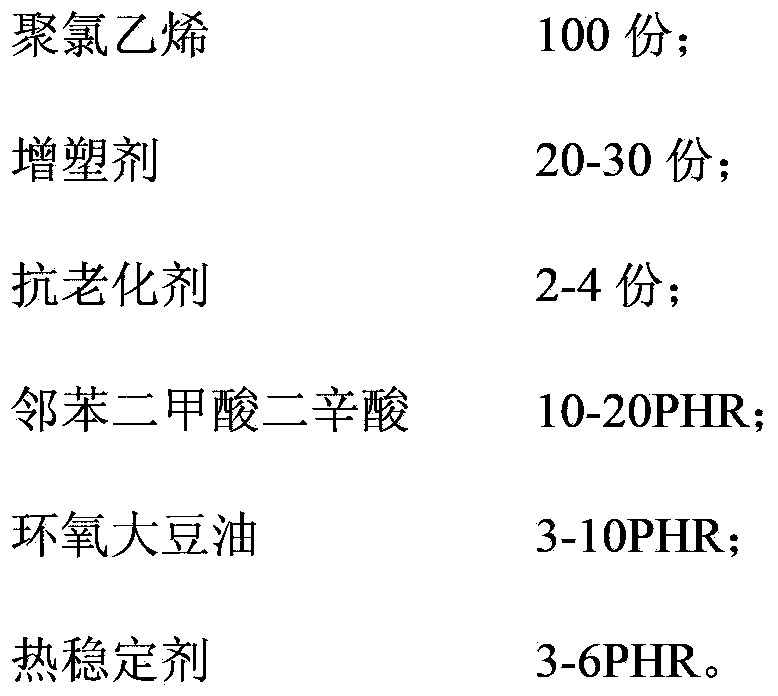

[0021] A PVC plastic floor comprising the following components mixed in parts by weight:

[0022]

Embodiment 2

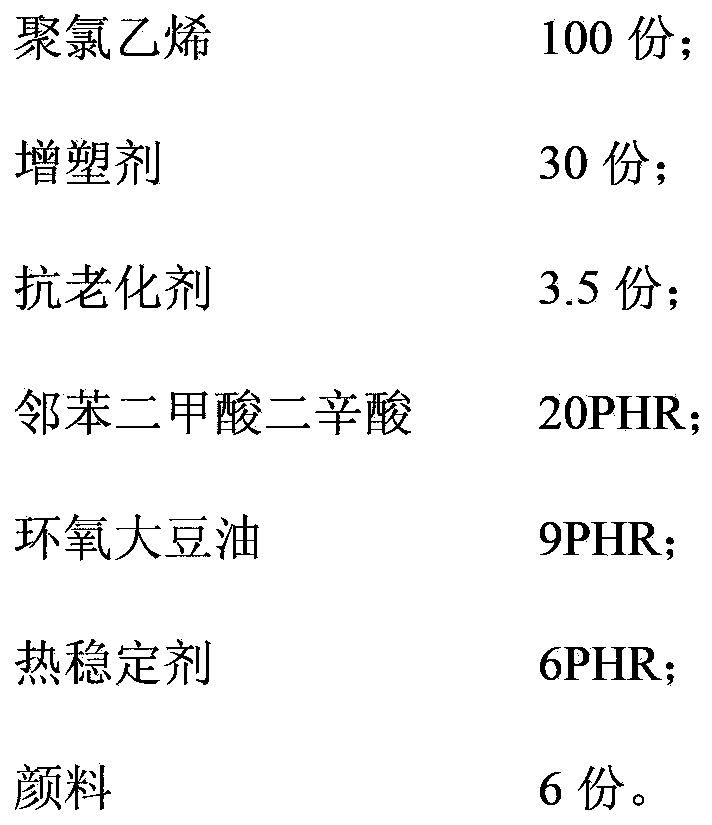

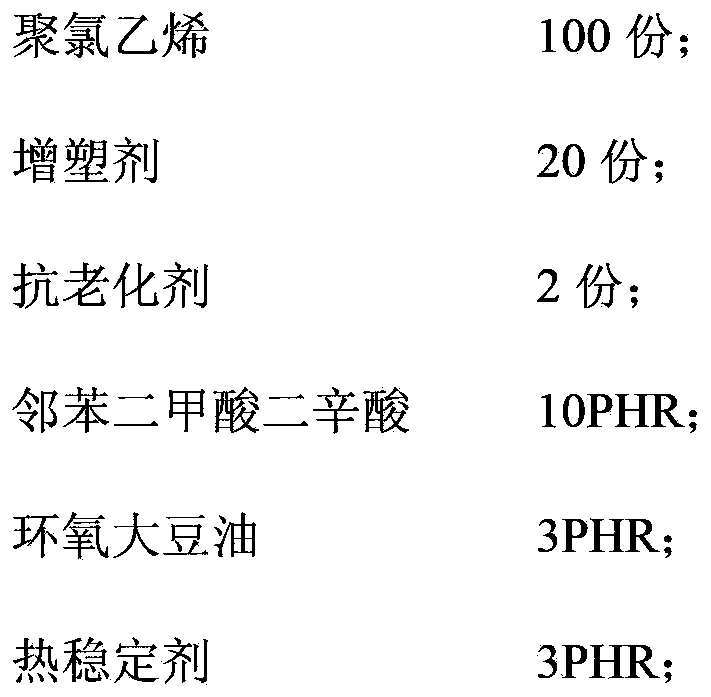

[0024] A PVC plastic floor comprising the following components mixed in parts by weight:

[0025]

[0026]

[0027] A kind of PVC plastic floor production technology, comprises the steps:

[0028] Step 1, mix the formula according to the above specific gravity and stir evenly;

[0029] Step 2, put the uniformly stirred ingredients into the plastic refining machine to pull the sheet, the temperature is 200 degrees;

[0030] Step 3, tablet pressing: temperature is 200 degrees, pressure is 210kg / cm 2 ;

[0031] Step four, extrude the finished product.

[0032] The PVC plastic floor produced by the invention has high mechanical properties, super mucous membrane properties, impact resistance, no deformation, environmental protection and reusability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com