Multi-resistant high-yield alcohol yeast mutant strain TT31 and screening method thereof

A technology of alcoholic yeast and screening method, which is applied in the directions of microorganism-based methods, biochemical equipment and methods, and treatment of microorganisms with electricity/wave energy, etc. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in combination with specific embodiments. The specific embodiments should be understood as illustrative only and not restrictive. The following examples cannot be used to limit the protection scope of the present invention.

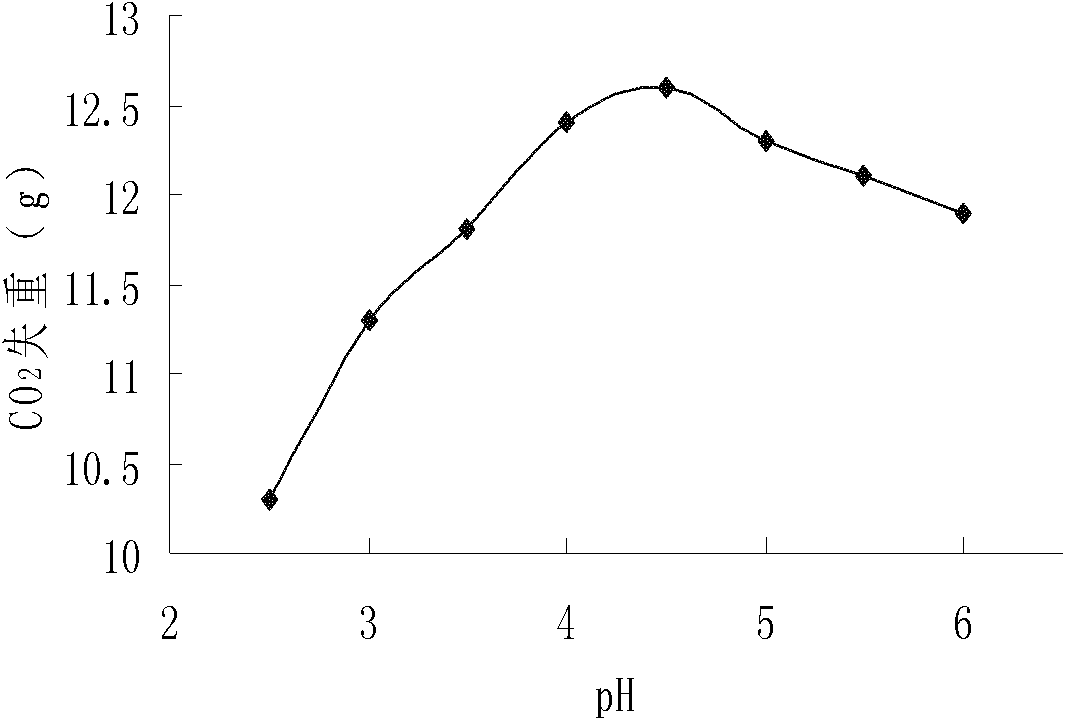

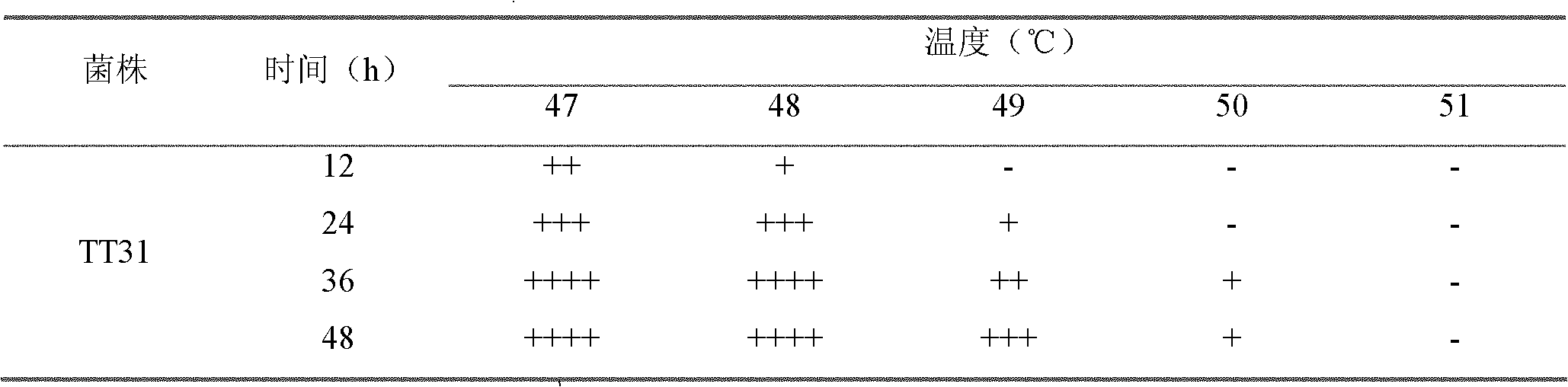

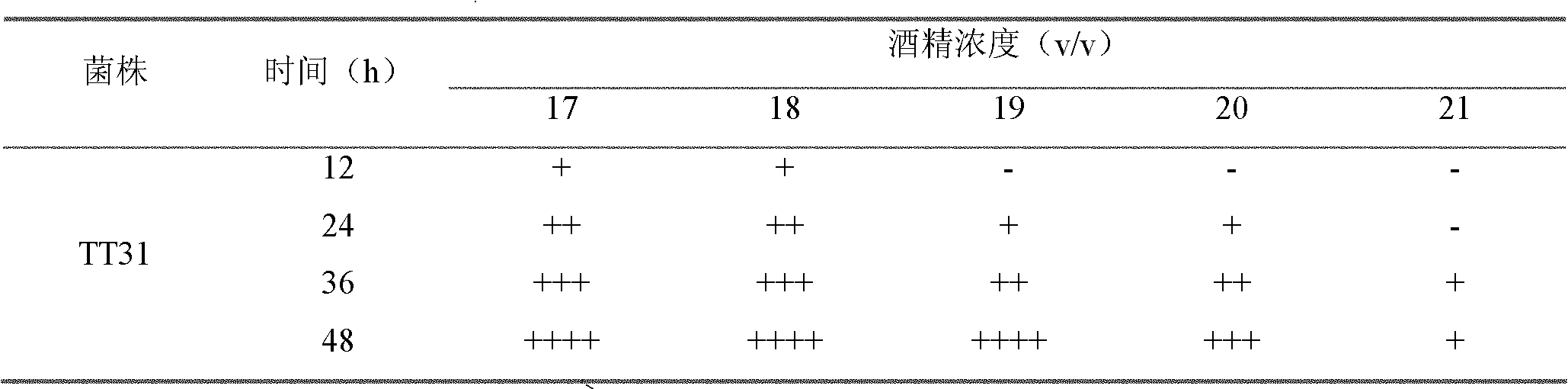

[0030] The technical route of the present invention is to perform ultraviolet mutagenesis on the starting strains, screen out the mutagenized strains that have a certain increase in tolerance and alcohol output during low pH fermentation, and then perform protoplast preparation and three rounds of genome reorganization on them, and go through TTC method one. Two-stage screening, two-stage screening by Dusley's tube fermentation, and three-stage screening by shaking flask fermentation, finally screened out yeast mutant strains with greater tolerance to acid, temperature and alcohol.

[0031] A multi-tolerant and high-yielding alcohol yeast mutant strain TT31, classified and named Saccharomyces crevisia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com