Water-based graphene flame-retardant PTC conductive paste, preparation method thereof and flexible conductive heating cloth

A water-based graphene, conductive paste technology, applied in flame-retardant fibers, textiles and papermaking, improved hand-feeling fibers, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

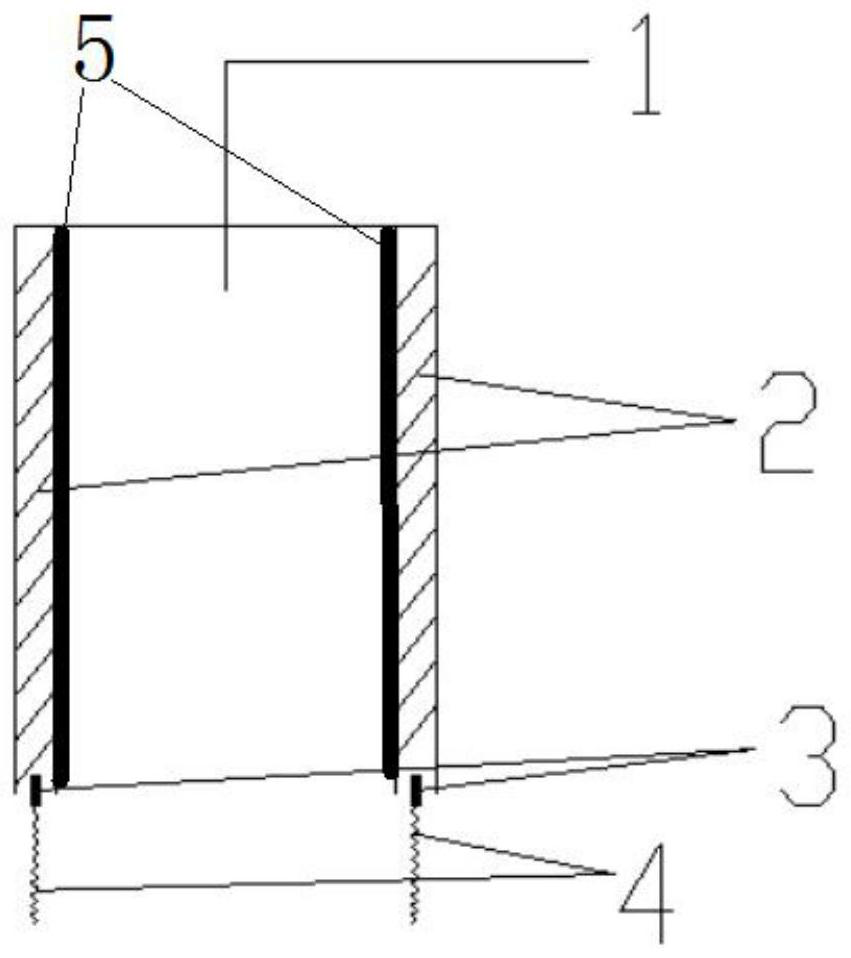

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the water-based graphene flame-retardant PTC conductive paste described in the above-mentioned technical scheme, comprising the following steps:

[0047] Mix the water-based flexible resin with water to obtain a resin solution;

[0048] mixing the resin solution, flame retardant and PTC functional components to obtain a dispersion;

[0049] The dispersion liquid, dispersant, auxiliary agent and conductive filler are mixed and ground to obtain the water-based graphene flame-retardant PTC conductive paste.

[0050] In the invention, the water-based flexible resin is mixed with water to obtain a resin solution. In the present invention, the mixing is preferably carried out under stirring conditions, the stirring speed is preferably 1000-1500 rpm, more preferably 1200-1400 rpm; the stirring time is preferably 5-10 min, more preferably 8-9 min .

[0051] After obtaining the resin solution, the present invention m...

Embodiment 1

[0069] Add 11.2g of flexible water-based acrylic resin, 3.8g of flexible water-based polyurethane and 40g of deionized water into a high-speed mixer, and stir for 8min at a speed of 1200rpm to obtain a uniform resin solution;

[0070] Add 2g of flame retardant PN-1, 0.8g of flame retardant PN-2, 5g of polycaprolactone and 5g of polyethylene into the above resin solution, stir at 1500rpm for 10min to obtain a dispersion;

[0071] Transfer the above dispersion into a sand mill, add 4.5g BYK9076, 2g anionic polyacrylamide, 0.5g leveling agent and 0.5g film-forming aid respectively, and add 12g conductive filler in 3 times, the conductive filler It consists of 2g of graphene and 10g of conductive carbon black, and is ground at a speed of 850 rpm until the average particle size is 1.5 μm to obtain a water-based graphene flame-retardant PTC conductive paste.

[0072] Arrange cotton with a size of 20cm×15cm in the water-based graphene flame-retardant PTC conductive paste, soak for 30...

Embodiment 2

[0077] Add 13.3g of flexible water-based acrylic resin, 2.7g of flexible water-based polyurethane and 40g of deionized water into a high-speed mixer, and stir for 10min at a speed of 1350rpm to obtain a uniform resin solution; mix 0.2g of dimethyl methylphosphonate, 1.8g Flame retardant PN-1, 1.2g flame retardant PN-2, 4g polyethylene, 4g maleic anhydride grafted polyethylene and 4g polypropylene were added to the above resin solution, stirred at 1650rpm for 8min to obtain a dispersion;

[0078] Transfer the above dispersion into a sand mill, add 3g of anionic polyacrylamide, 4g of BYK9076, 0.5g of defoamer 901W and 0.2g of thickener, and add 15g of conductive filler in 4 times. 3g of graphene, 10g of conductive carbon black and 2g of nano-graphite were ground at a speed of 1500 rpm until the average particle size was 0.9 μm to obtain a water-based graphene flame-retardant PTC conductive paste.

[0079]Arrange polyester with a size of 20cm×15cm in the water-based graphene flam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com