Tubular PERC two-sided solar cell, preparing method thereof and electroplating equipment special for tubular PERC two-sided solar cell

A technology for double-sided solar cells and electroplating equipment, applied in the field of solar cells, can solve the problems of poor electrode conductivity uniformity, high cost, and large shading area, and achieve the effects of increasing conductivity uniformity, avoiding corrosion, and improving uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

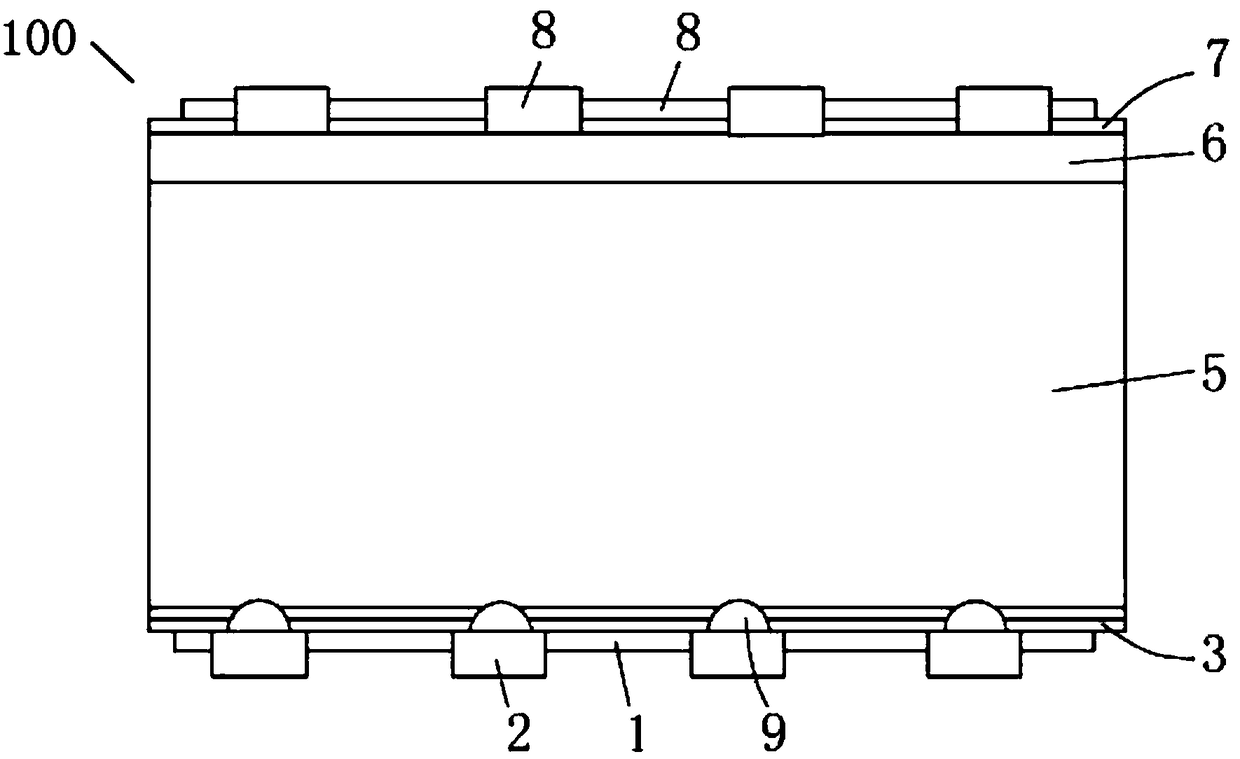

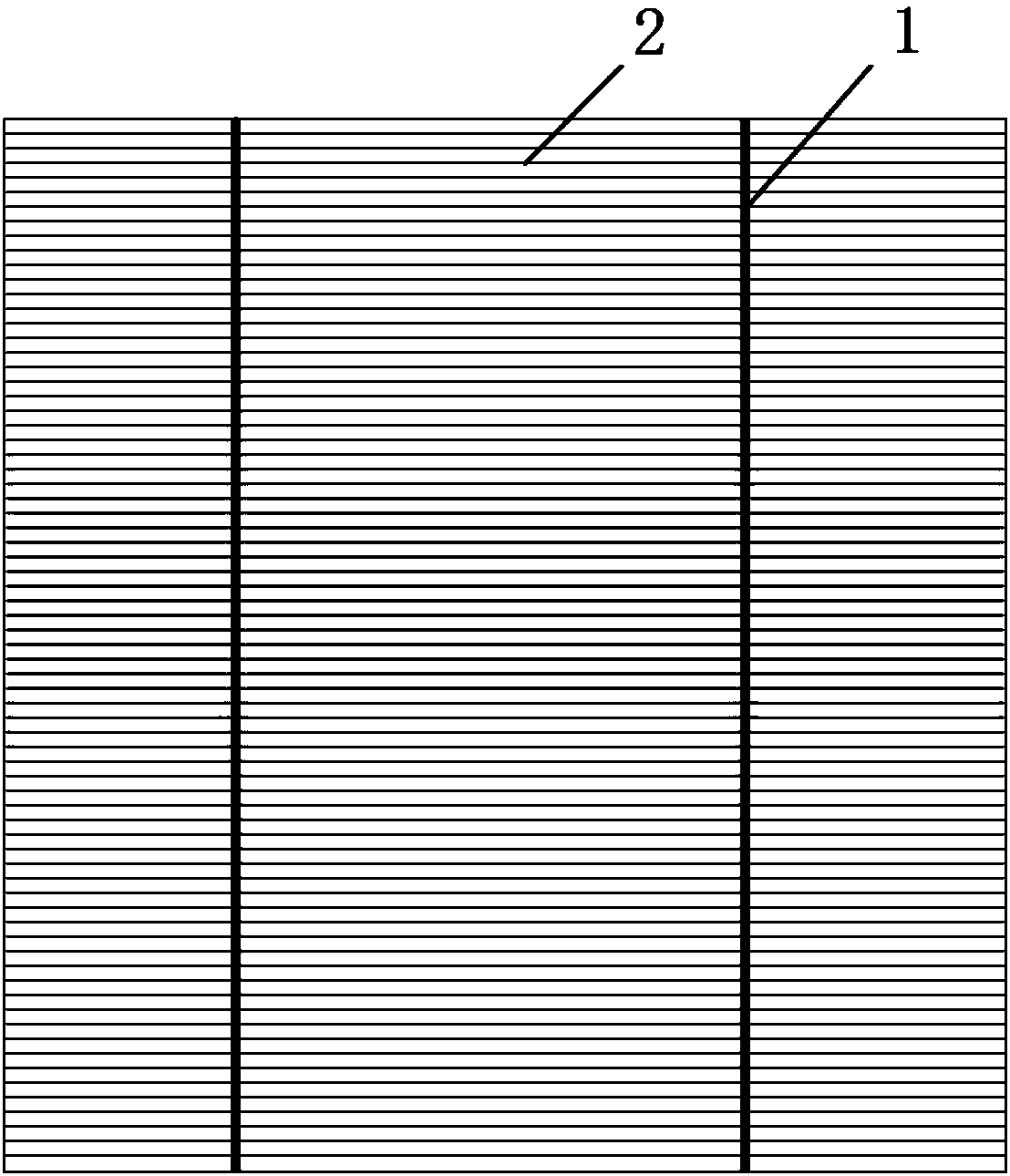

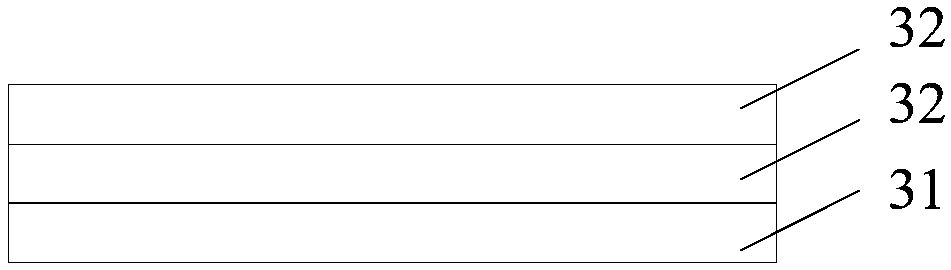

[0052] Such as figure 1 As shown, the present invention provides a tubular PERC double-sided solar cell 100, including a back silver busbar 1, a back aluminum grid line 2, a back composite film 3, a P-type silicon 5, an N-type emitter 6, and a front passivation film. 7 and positive electrode 8; the back composite film 3, P-type silicon 5, N-type emitter 6, front passivation film 7 and positive electrode 8 are sequentially stacked and connected from bottom to top;

[0053] After the back composite film 3 is laser grooved, 30-500 groups of laser grooved areas arranged in parallel are formed, and at least one group of laser grooved units 9 is arranged in each laser grooved area, and the back aluminum grid line 2 passes through the laser grooved area. The grooved are...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com