Conductive microfiber leather as well as preparation method and equipment thereof

A technology of microfiber leather and microfiber, applied in fiber type, fiber treatment, textiles and papermaking, etc., can solve the problems of material strength to be further improved, weak bonding force, etc., achieve simple structure, improve electrical conductivity, and enhance adsorption capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to enable those skilled in the art to clearly understand the present invention, the present invention will now be described in detail in combination with specific implementation methods and accompanying drawings.

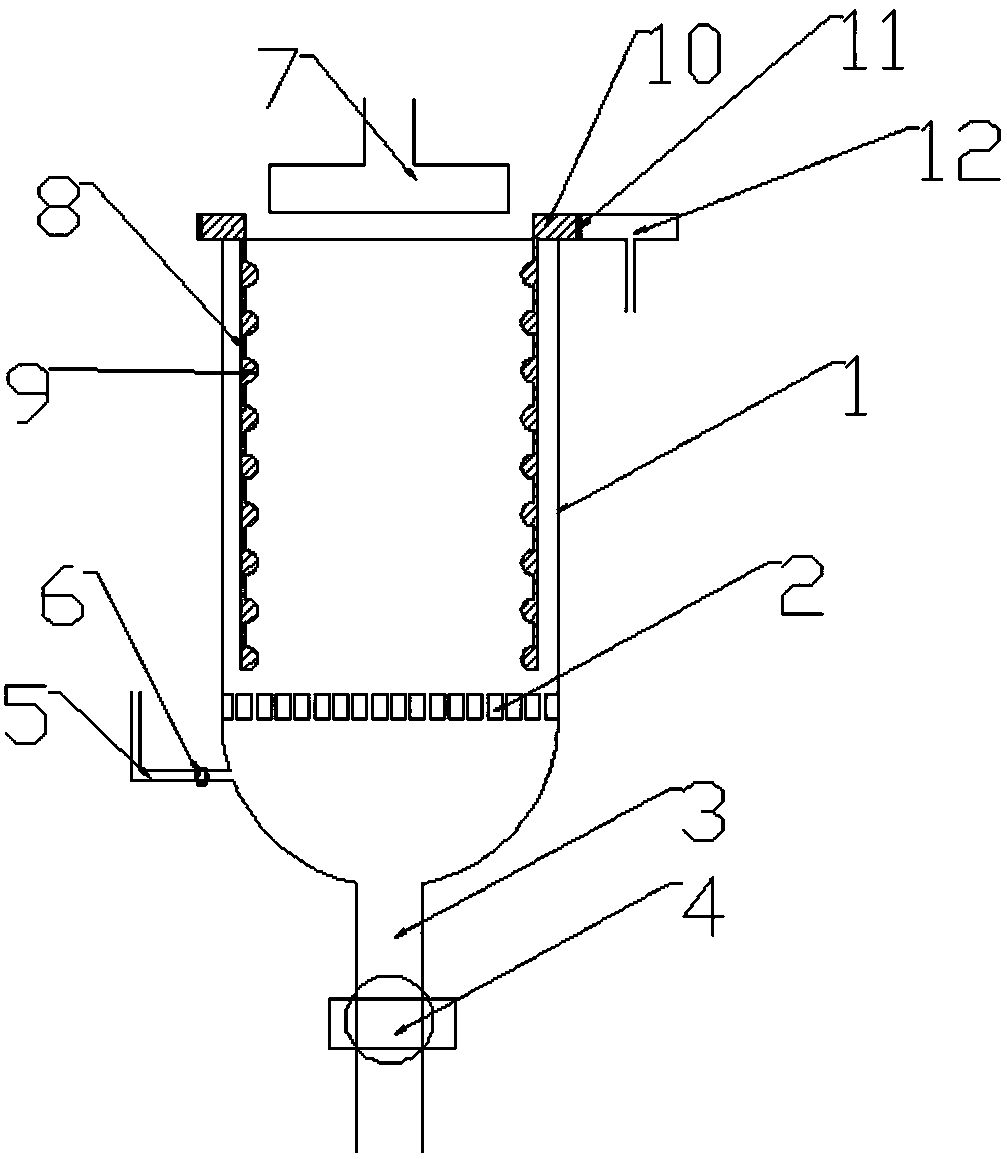

[0034] Such as figure 1 As shown, the device adopted in the present invention is based on the assembly line for preparing microfiber leather from conventional microfiber staple fibers, and also adds a microfiber staple fiber opener and a microfiber staple fiber treatment pool. Described superfiber short fiber treatment pond has funnel barrel-shaped wall 1, is provided with porous filter plate 2 at the bottom of funnel barrel-shaped wall 1, waste liquid outflow pipeline 3 and switch 4 are set below porous filter plate 2, in porous filter plate A gas inflow channel 5 and a switch 6 are arranged between the plate 2 and the waste liquid outflow pipe 3 , and a cake-shaped extruder 7 is also arranged above the barrel-shaped wall 1 of the funnel.

[0035] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com