Panel sliding frame

A sliding frame and plate technology, which is applied to conveyor objects, transportation and packaging, rollers, etc., can solve the problems of leaving traces on the plate and affecting the appearance of the plate, achieve balanced heat dissipation, ensure the quality of the veneer, and reduce labor costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now in conjunction with accompanying drawing, the present invention is described in detail:

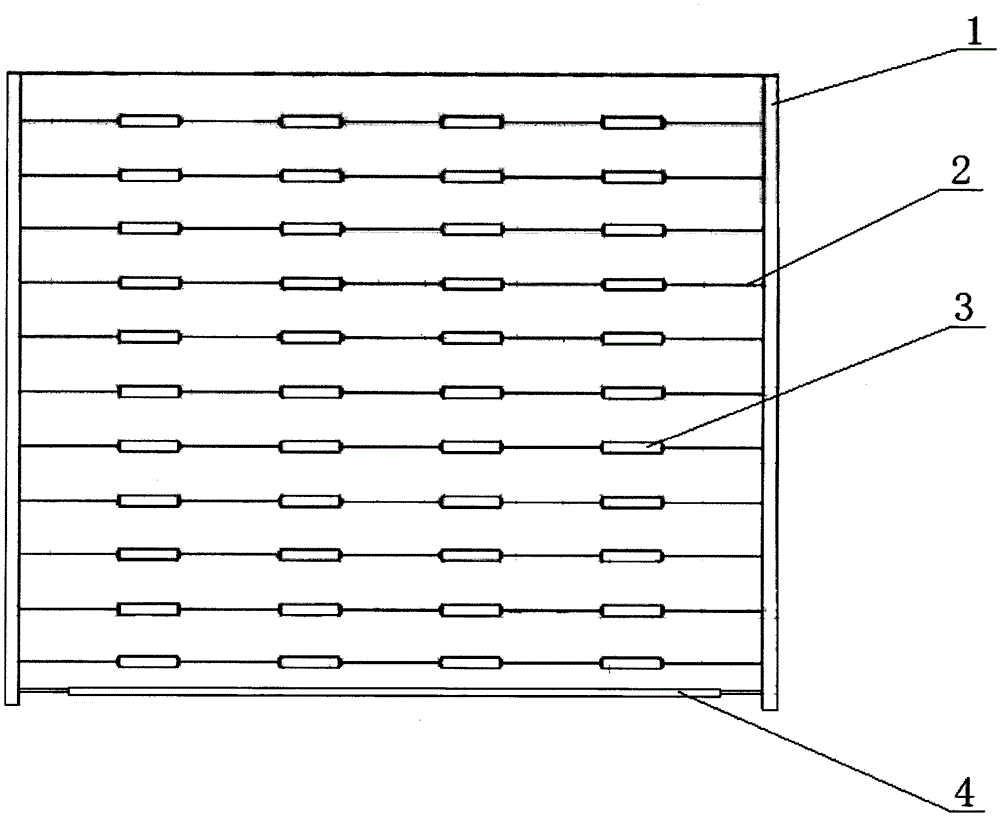

[0018] The invention is composed of a frame body (1), a rotating shaft (2), an idler roller (3) and a baffle frame (4).

[0019] figure 1 Shown is the structural representation of the present invention. The present invention is made up of frame body (1), rotating shaft (2), idler roller (3), baffle frame (4); wherein, several idler rollers (3) are arranged on rotating shaft (2), and There are several groups of rotating shafts (2) installed on the frame body (1). When installing, the rollers (3) on each group of rotating shafts (2) are in a parallel state, and the baffle frame (4) is placed on the side of the frame body (1). front, and then form a whole.

[0020] Application principle of the present invention:

[0021] The present invention is placed next to the hot press, and after the hot-pressing program of the synthetic board is completed, the board is pushed onto the sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com