Full-glazed porcelain tile as well as preparation method thereof

A technology for fully polished glaze and porcelain tiles, applied in the field of porcelain tile production, can solve the problems of low grade rate, high cost of screen printing and glaze process, complicated process, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The invention is a kind of fully glazed porcelain brick, which comprises a body and a surface glaze on its surface. The upper layer of the surface glaze is covered with a fully polished glaze. The body is designed to have a water absorption rate of ≤0.5%. ℃.

[0029] The following is the blank formula suitable for the production of glazed tiles, and its chemical composition is shown in Table 1.

[0030]

[0031]

[0032]

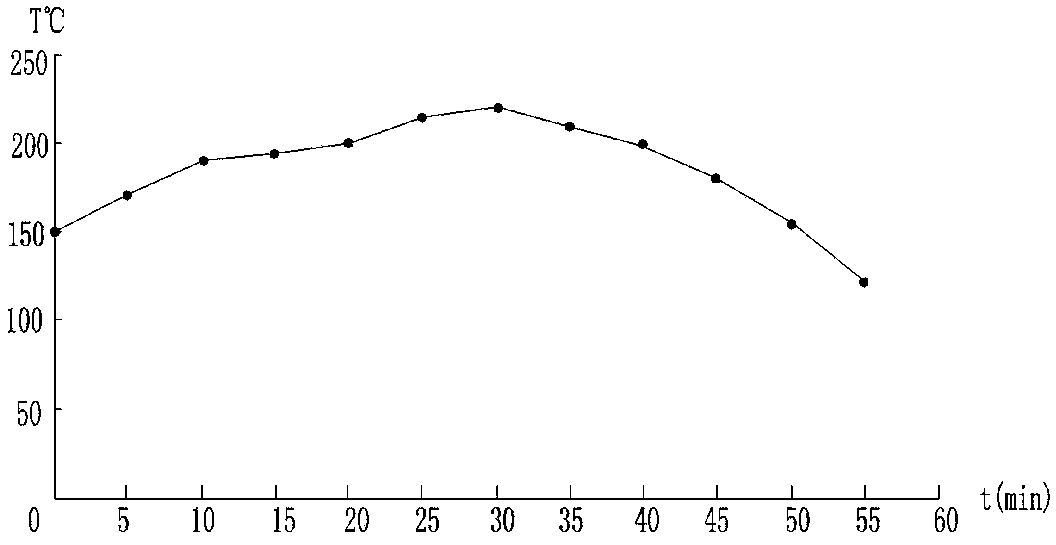

[0033] According to the commissioned billet formula, carry out accurate batching, ball milling, the fineness is controlled to be 250 mesh sieve (1.2-1.6)%, the water content is 33.5%, and it is sieved, iron-removed, sprayed and granulated into powder; at 3800T Under the machine, it is pressed under the pressure of 3250T, and the product size is 600mm×600mm. It is dried in a drying kiln at 220°C for 55 minutes, and the dried blank enters the glaze line after drying. Drying kiln drying temperature curve see figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com